SEQUENCES OF OPERATION CONTINUED

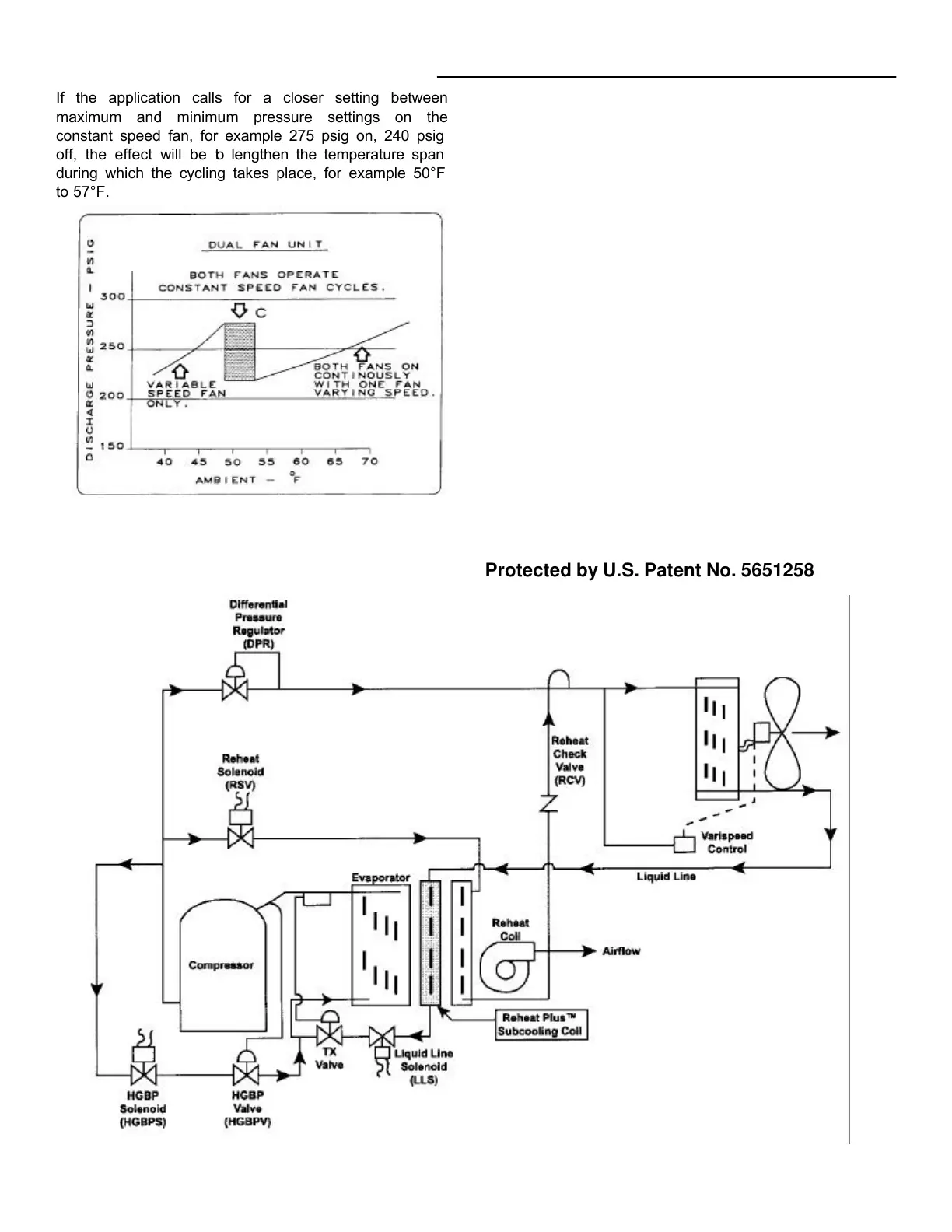

If the application calls for a closer setting between

maximum and minimum pressure settings on the

constant speed fan, for example 275 psig on, 240 psig

off, the effect will be to lengthen the temperature span

during which the cycling takes place, for example 50°F

to 57°F.

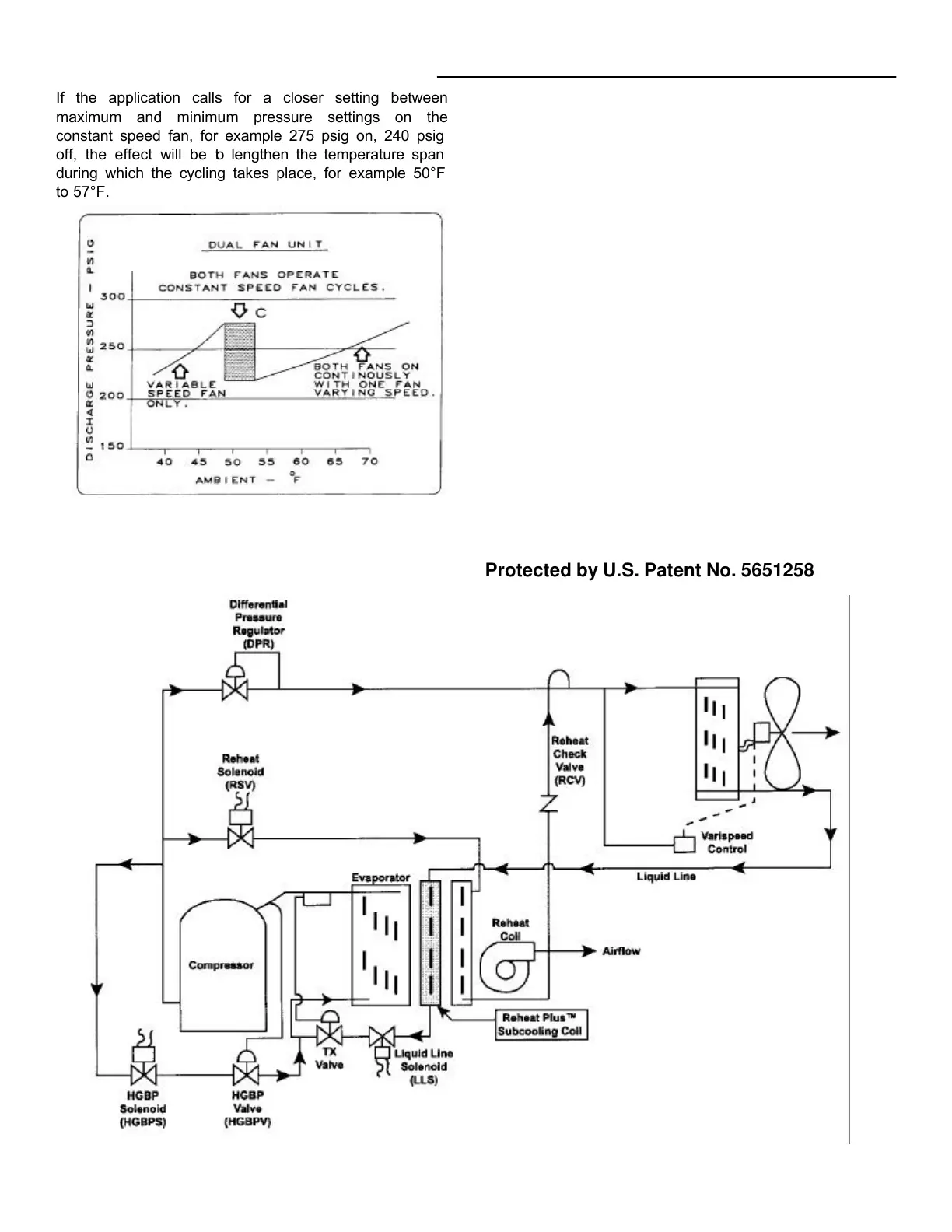

Optional Hot Gas Reheat

Factory installed hot gas reheat circuit includes outlet

regulator valve, check valves, hot gas solenoid operated

control valve, variable speed condenser head pressure

control, one stage sensor, and one row heat reclaim coil.

The coil is equal to the evaporator face area and

installed in the reheat position. The sensor is factory

mounted. Hot gas reheat may not be operated below

60°F. ambient temperature.

Optional Reheat Plus

To lower relative humidity (RH) in the supply air stream,

a one row subcooling coil, generally equal to the

evaporator face area may be specified. The refrigerant

liquid passes through the tube side, adding up to 40°F.

of subcooling. For every two degrees of subcooling, the

compressor capacity is increased one percent. This is

also reflected as an increase in efficiency. The resulting

heat is passed into the air stream as reheat, usually 8°F

to 10° F. at 200 cfm/ton, thus the lower discharge air

relative humidity.

Reheat Plus™ Subcooling Reheat System Protected by U.S. Patent No. 5651258

Loading...

Loading...