Maintenance and Repair

Daily maintenance:

1.The vehicle should be ept clean and clean, and the vehicle should be wiped with dry cloth in time after being

drenched to avoid rusting of parts and short circuit of electrical components.

2.Always chec the air storage capacity of the tire to eep it in normal use.

3.The main transmission parts such as front ale, a roar ale, conter ale, front for, Flywheel and electric hub

should be checed and adusted freuently to eep the transmission parts eible without impact sound and

noise Chec the screws and nuts of the

bicycle, if it is found that it is loose, it should be tightened in time to

prevent the parts from being worn out or causing greater damage and fracture due to looseness.

4.The braing part should be checed and adusted freuently to mae it in a eible state, for eample, the gap

between the brae rubber and the gate core should not be too large.

5.Always chec whether the operating parts and cable are eible, and ensure that there is no stagnation, no

stagnation, and properly drip lubricating oil from one end of the hose slowly, and pull the wire rope at the same

time, feel that the wire rope slides lightly in the hose.

6.Electric bicycle moving parts should be often inected with a small amount of lubricating oil to reduce wear and

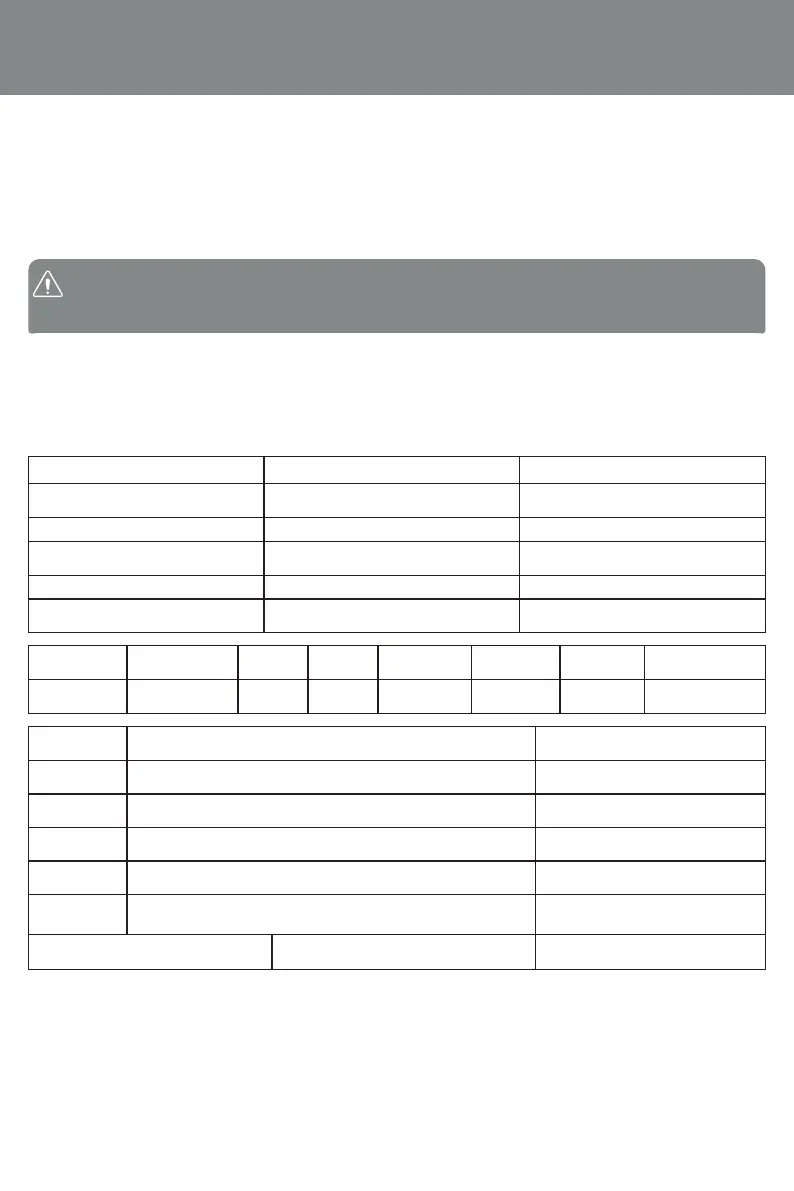

eep riding light, as shown in the following table:

Correct use and maintenance methods of motor, controller and battery:

1.The motor should be ept clean, no foreign matter, corrosive liuid, gas, etc. should enter the motor, and the

motor hell should not be noced and baed to avoid damage to the motor.

2. All wires should avoid friction and contact with sharp metal, and the wires should be tied rmly with the frame.

3.The controller is a high-tech intelligent computer memory program password. If the user opens the repair by

himself, the components will be easily damaged. If the controller fails, please go to the service department to

repair it.

4.This battery is a special battery for electric bicycles. hen the electric bicycle is not used for a long time, the

battery should be stored after sucient electricity, and the electric energy should be replenished regularly to

avoid battery vulcaniation caused by long-term under power.

5.The battery cannot be near open ame or high temperature heat source, and the battery cannot be thrown

into the re. Direct eposure to the sun is strictly prohibited in hot and hot weather.

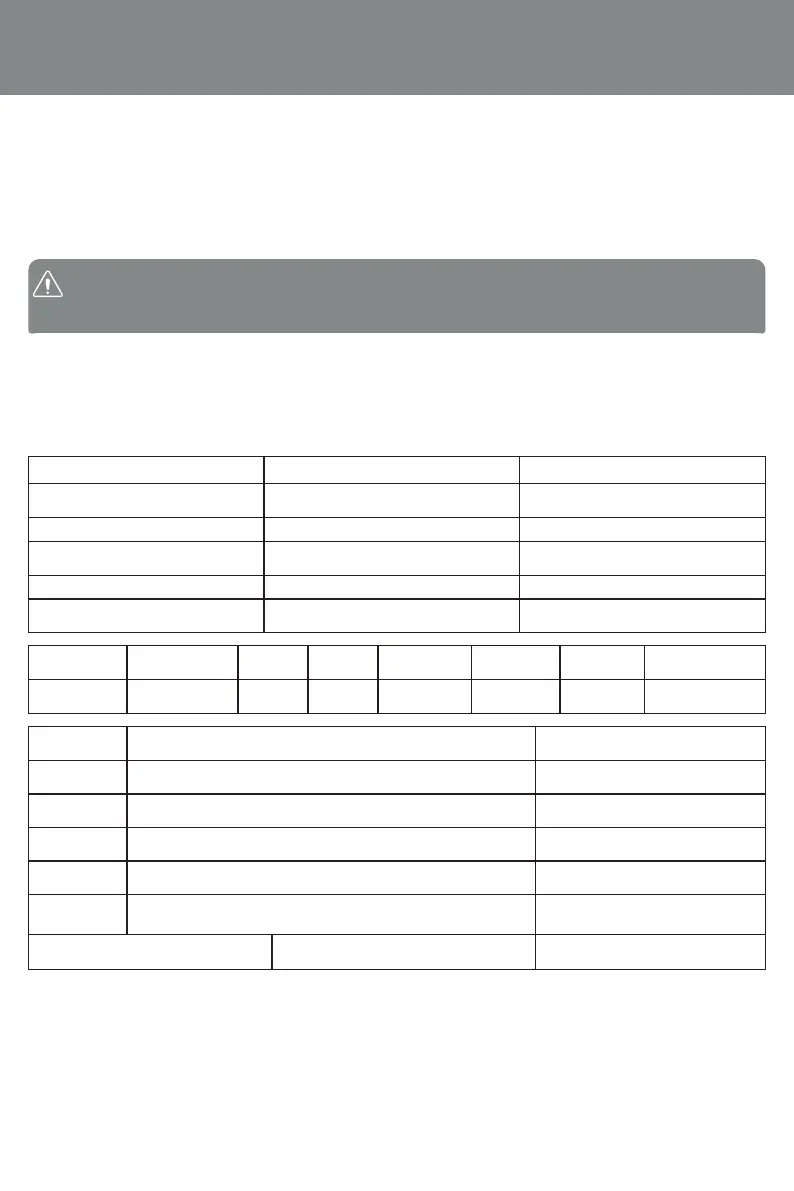

Note that the tightening torue of front wheel, handlebar core screw rod, saddle pipe clamping Bolt and

saddle clamping Bolt shall not be less than18N.mThe tightening torue of rear wheel, bottom bracet Cup

and bottom bracet Cup loc nut shall not be less than 30N.m

Front ale, center ale, a rear

ale bearing

3 calcium-based lubricating oil

i months to one year

alf a year

alf a year

alf a month

alf a month

3 calcium-based lubricating oil

3 pieces of calcium-base

lubricating oil

30 mechanical oil

30 and mechanical oil

front fork headset

edal bearing

Chain

Double support locking plate side

support and transmission parts

Name

andle

horizontal tube

stem Saddle Saddle pipe front ale rear ale Center shaft nut

Running torque 18N. m 18N. m 18N. m 18N. m 18N. m 30N. m 30N. m

Lubrication part Lubricant Lubrication cycle

Location Method Time

Center shaft

Front and

rear wheels

brake cable

brake handle

Chain

Front and rear nut, handlebar

core screw, saddle clamping screw

Chec whether the bottom bracet Cup is loose/disassemble

the central shaft, wash and change oil, and chec the parts.

Chec the wheel swing, spoe tension, spoes, mother spoe

for damage Adust the wheel

If there is a steel wire at the root of the rolling head,

replace the new brae line.

If there is a steel wire at the root of the rolling head,

replace the new brae line.

Chec whether the pin shaft is loose or bulging, and

whether the etension of the chain is too large.

Chec for looseness

Chec freuently /once every year

The rst month/year after the

rst new car

nce every month

nce every three months

nce every si months

nce every si months

12

Loading...

Loading...