Water/Methanol Injection V2

13

© 2020 AEM Performance Electronics

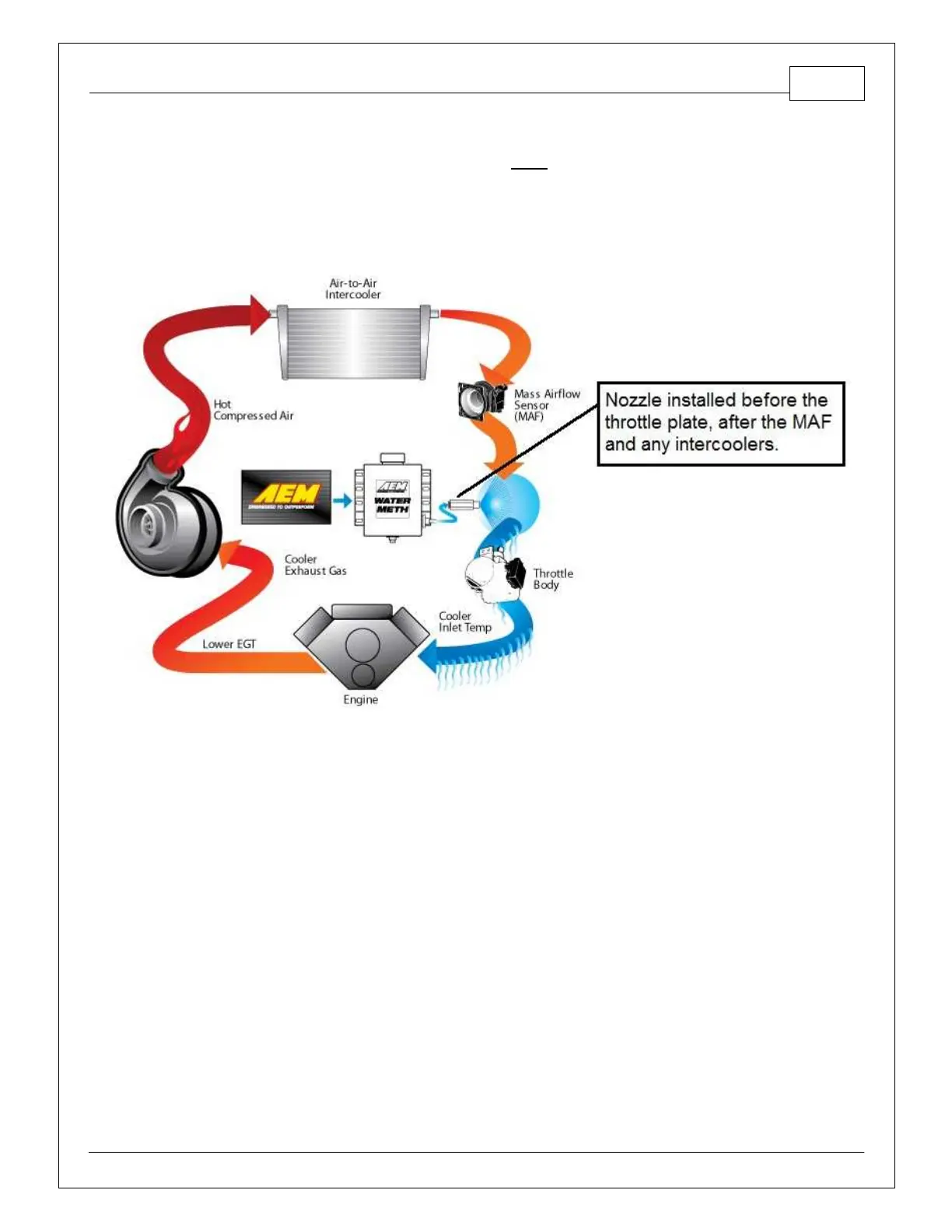

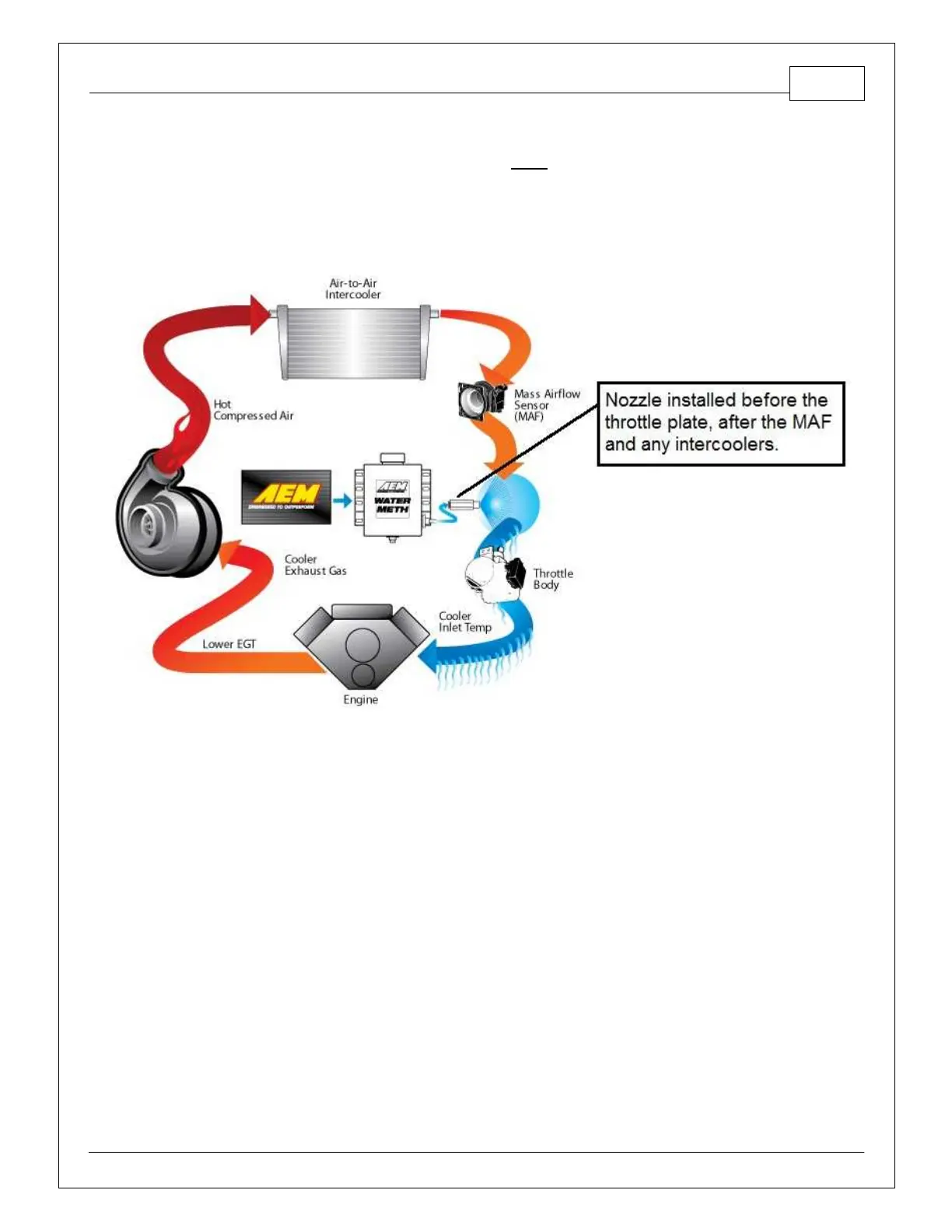

Nozzle Mounting

Select the location where the nozzle will be installed. Nozzle must be mounted such that it is higher than

the tank. Failure to do so may lead to fluid leaking into the intake tract due to gravity or siphoning,

which may result in engine damage. Nozzle must be mounted before the throttle plate. Nozzle should also

be mounted after the MAF sensor, if present. Nozzle must also be mounted after any intercoolers. In most

instances, mounting the nozzle 6–8” ahead of the throttle body provides an excellent combination of air charge

cooling and combustion control.

In most instances, the air charge piping can be drilled and tapped for 1/8” NPT to directly mount the nozzle. If

using thin walled tubing it’s suggested that a bung be welded to the piping. Mounting hole should be tapped

deep enough to allow the end of the nozzle to be nearly flush with the interior of the intake once the nozzle is

fully installed.

Pump/System Check

The TEST push button on the controller module can be used to test the system. Press and hold the button to

activate the pump. The pump speed will gradually increase from zero to full speed within 3 seconds and then

remain full for another 3 seconds before stopping. When the button is released the controller will return to

normal operation.

Add water to the tank and, with the nozzle pointed into a container, press and hold the TEST button. The flow

will start gradually and increase to a steady amount. If this happens, then your system is connected properly.

Check and repair any leaks. Drain the water out of the tank and install the nozzle.

Fluid Compatibility

Under NO circumstances should any hydrocarbon based fuel ever be used with this system. Water and

methanol are the ONLY fluids to be used.

Loading...

Loading...