Water/Methanol Injection V2

19

© 2020 AEM Performance Electronics

ENGINE TUNING

Water/methanol injection is generally not considered a bolt-on power adder for forced induction gasoline

applications. Engine tuning is usually required in order to maximize potential power gain. Water/methanol

injection allows for a more aggressive tune to be used while still using pump gas as your base fuel.

Using a 50/50 mix of water/methanol is recommended for the best combination of air charge cooling and

detonation control. With conservative boost and timing, establish a base AFR that is one point higher than your

final target AFR. For example, if your final target AFR with water/methanol injection is 11.0:1, set your base AFR

to 12.0:1. Once the base AFR has been set, start injecting water/methanol and adjust the injection flow rate to

achieve your final target AFR. For example, if before injection your base AFR is 12.0:1 and then during injection

your AFR drops to 10.5:1, reduce the water/methanol flow rate until your final target AFR is reached. It is

generally recommended that the flow rate of the injection system be changed in order to reach your target AFR

and NOT your primary fueling. Injection flow rate adjustments can be made by changing your nozzle selection

or by adjusting the “Start PSI” and “Full PSI” settings.

Once the injection flow rate is set to deliver your desired final AFR, boost and ignition timing can be increased to

take advantage of the additional air charge cooling and detonation control. When injecting the correct amount, a

50/50 mix of water/methanol has been shown to provide an effective octane of over 110 when using a base fuel

of 91–93 octane pump gas. A properly tuned water/methanol injection system will usually support a typical “race

gas” engine tune.

COLD WEATHER OPERATION

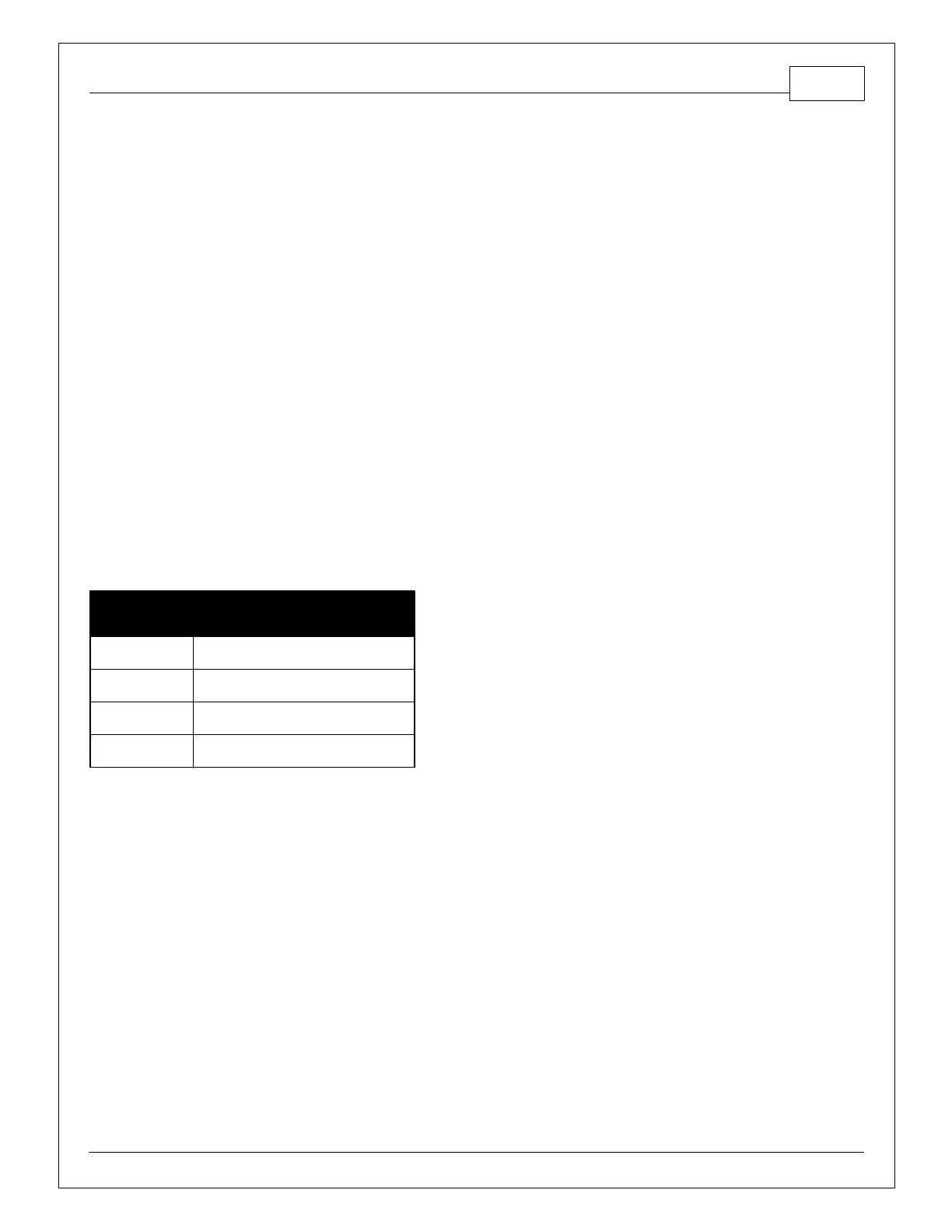

A water/methanol mix will also lower the freezing point of the fluid. Below is a chart with freezing points for

different percentages of water/methanol mixtures.

Methanol Concentration % by

Volume

MAINTENANCE

The injector nozzle should be cleaned periodically. Disassemble the nozzle and clean it with a suitable cleaner

until all debris is removed. If excessive contamination is found, check the rest of the system for the source.

Loading...

Loading...