INSPY. 1003. 4138305_03

12

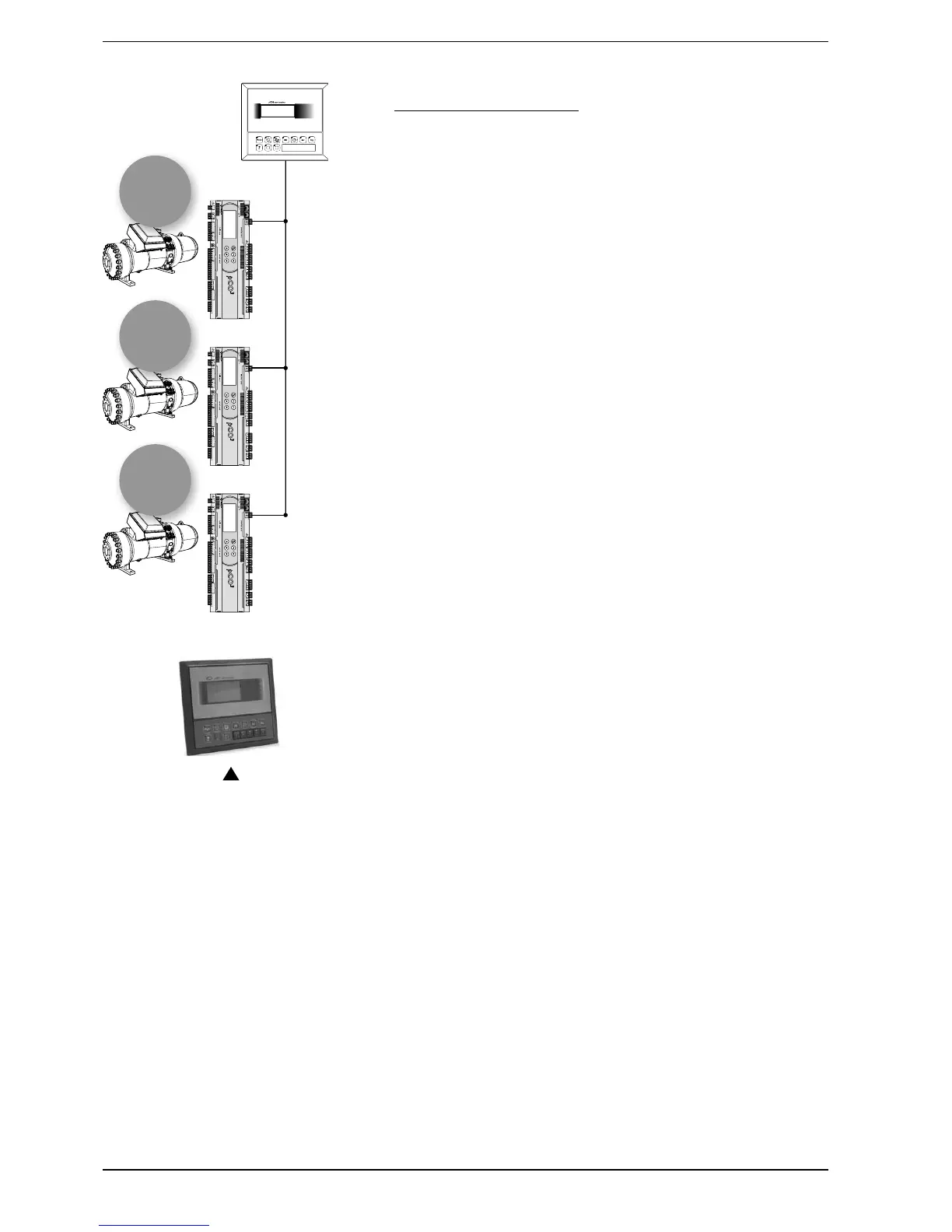

4.6. ELECTRONIC REGULATION

Electronic regulation on the NS chillers

consists of control cards for each compres-

sor connected to each other in a network

and a control panel with display, see figure.

In the case of models with more than one

compressor, the card that controls com-

pressor 1 is the “MASTER” card, while the

others are “SLAVE”. On each card, trans-

ducers, loads and alarms are connected

to the compressor that commands while

the general machine ones are connected

only on the master card. The program and

parameter pre-set are stored permanently

in the controller’s FLASH memory, to ensure

that they are kept in memory even when

the system is not powered (without the

need for an auxiliary battery).

The connection to the serial supervision as-

sistance line in accordance with the RS485

standard, is performed through the serial

card ACCESSORY RS485P1 and the com-

munication protocol.

• The terminal, which is always controlled by

microprocessor, is equipped with a display,

a keypad and a set of LEDs, and is used

for programming control parameters (Set

Points, differential band, alarm threshold)

and for fundamental user operations (ON/

OFF, display controlled values).

The terminal does not need to be con-

nected to the pCO for normal controller op-

eration, and is necessary only when initially

programming the basic parameters.

Microprocessor

−

Remote on/off with external contact

without power

− Multi-lingual menu

− Phase sequence control

− Independent control of individual

compressors

− Ammetric transformer

− Cumulative failure block signalling

− Alarm log function

− Daily/weekly programming

− Inlet/outlet water temperature display

− Alarm display

− Full proportional regulation of the out-

put water temperature

− Programmable timer function

− Function with double setting point con-

nected to an external contact

− Fan regulation

− Interfaceability with the Modbus proto-

col (accessory)

− Pump/s control

− Compressor rotation control

− Analogue input from 4 to 20 mA

− Outside air temperature sensor

− Function "Always Woking" In the case

of critical conditions (e.g. ambient tem-

perature that is too high) the machine

does not stop but is able to regulate

itself and provide the maximum power

that can be generated in those condi-

tions.

− Self adapting operating differential

“Switching Histeresys” to ensure the cor-

rect compressor functioning at all times

even in plants with a low water content

or insufficient flow rates. This system

reduces the compressor wear

− The AFFP “Anti Freezing Fan Protection”

system that turns on the fans periodi-

cally when the external temperatures

are very low

− The PDC “Pull Down Control” system

to prevent the activation of the power

steps when the water temperature is

approaching the set point quickly. It

optimises the operation of the machine

both when running normally or when

there are load variations, thereby

assuring top machine efficiency in all

situations.

For further information, refer to the user

manual.

pCO

3

MASTER

pCO

3

SLAVE

pCO

3

SLAVE

SINGLE

Compressor

BI

Compressor

TRI

COMPRESSOR

Terminal on the machine

Loading...

Loading...