AirSep

®

Corporation

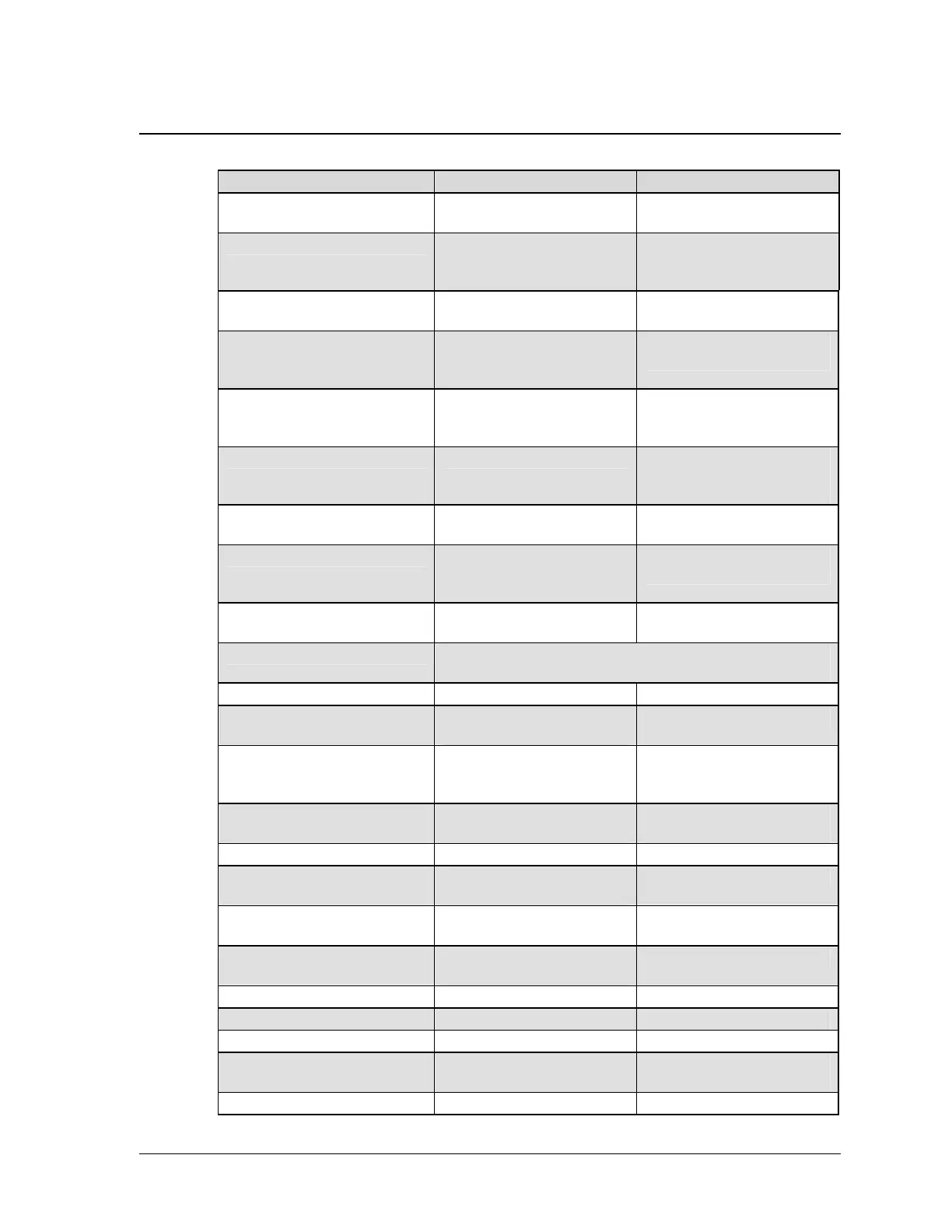

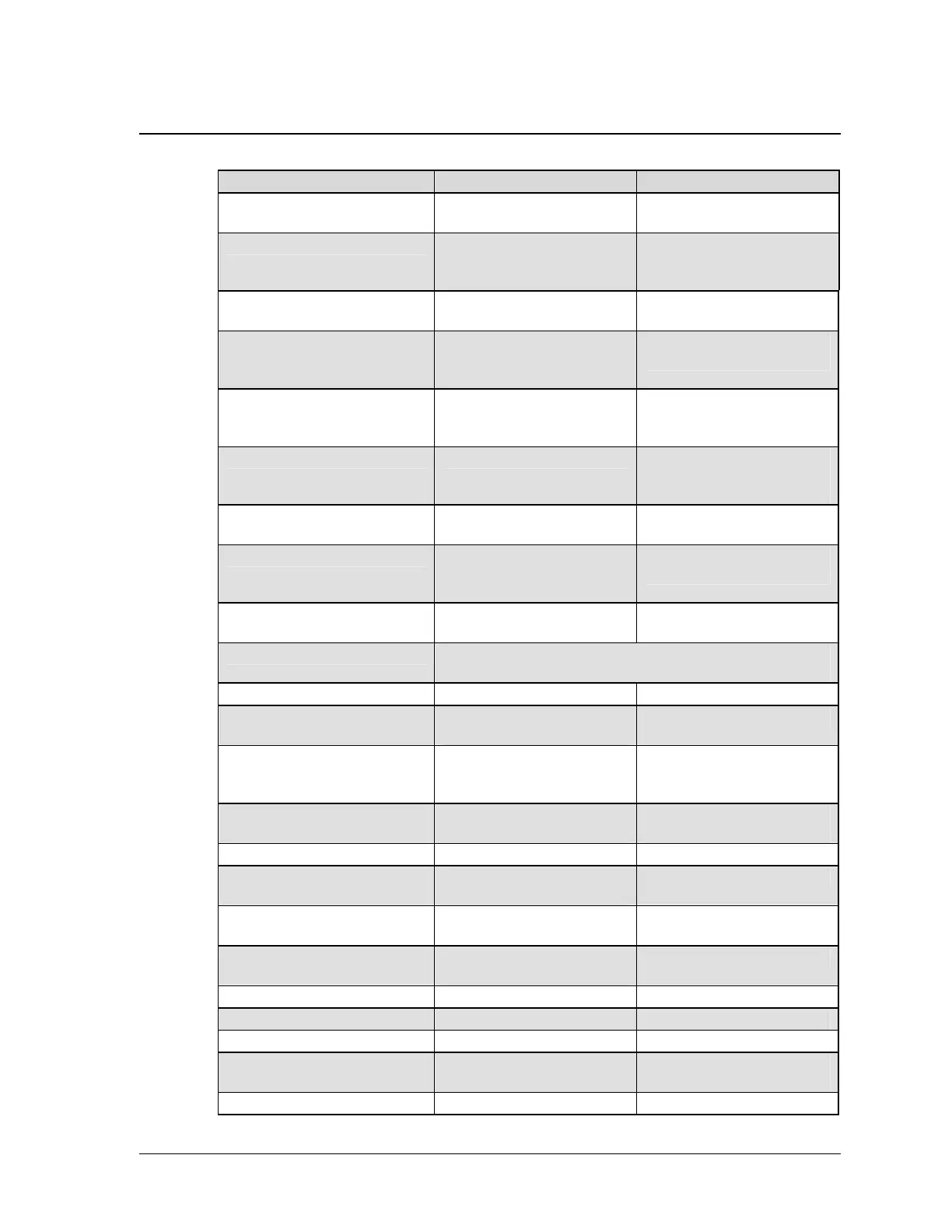

AS-A—AS-P Series Instruction Manual 8-3

Problem Probable Cause Solution

Inadequate cycle

pressure.

Adjust or replace feed air

regulator.

Oxygen demand exceeds

oxygen generator

capacity.

Check oxygen usage or

check unit and oxygen

hoses and piping for leaks.

Oxygen purity below

specified purity (50–70%).

Low purity oxygen during

initial start-up.

Start unit as described in

Chapter 6.

Unit shut down for

extended period—no

pressure in oxygen system.

Start unit as described in

Chapter 6.

Momentary power loss. Vent low purity oxygen

from system as described

in Chapter 6.

Inadequate feed air. Check air lines for

obstructions or adjust or

replace feed air regulator.

Valves not cycling

properly.

See valve sequence in

Appendix A.

Improperly wired or

defective circuit

board/PLC.

Check the wiring or

replace circuit board/PLC.

Torn valve diaphragm. Identify defective valve

and rebuild valve.

Solenoid valve not functioning properly. Check for the

following causes:

Defective coil. Replace coil.

Loose or defective wire to

valve.

Repair or replace wire.

Defective circuit

board/PLC. (No power

output to valve.)

Replace circuit board/PLC.

Valve remains energized

and open.

Check the valve or the

circuit board/PLC.

Defective valve. Rebuild valve.

Worn internal parts on

valve.

Rebuild valve.

Valve makes loud

“chattering” noise.

Low voltage. Check power supply.

Low voltage circuit

board/PLC output.

Replace circuit board/PLC.

Dirty valve. Clean or rebuild valve.

Worn valve core. Rebuild valve.

Defective EMI filter. Replace EMI filter.

Very low purity oxygen

output (21–50%).

Leaking check valves. Clean or replace check

valves.

Plugged muffler. Replace muffler.

Loading...

Loading...