SER 3620 Electronic-Metered Control Valve

Revision (11-05) 8 Alemite LLC

Assembly

NOTE

: Prior to assembly, certain compo-

nents require lubrication. Refer to

Table 2

for details.

Control Valve Handle

NOTE

: Refer to

Figure 6

for a section

view of the control valve handle assembly.

1. Install Roll Pin (

31

) into Body (

30

) as required.

IMPORTANT: Lubricate O-Rings (

42

)

with grease prior to installation.

2. Install O-Rings (

42

) onto Cam (

43

).

3. Install the Cam assembly into the Body.

• Make sure to orient the Cam as shown in

Figure 5

.

4. Position Lever Assembly (

40

) onto the tabs of the

Cam.

• Make sure the safety does not interfere with the

Body.

5. Install Screws (

41

) that secure the Lever Assembly

to the Cam.

• Tighten the Screws securely.

6. Install Seal (

33

) [blunt end first] onto Push Rod (

32

).

7. Install Spring Support (

35

) into the small end of

Compression Spring (

36

).

8. Install Small Compression Spring (

34

) onto the

Spring Support.

9. Install the Push Rod and Seal assembly onto the

Spring Support.

10. Install the Compression Spring (with assembled

components) into the Body.

• Make sure the Push Rod seats properly on the

Cam.

11. Install Strainer (

37

) into the Compression Spring.

12. Install O-Ring (

38

) onto Swivel Assembly (

39

).

NOTE

: Swivel Assembly is under Spring pres-

sure during installation.

13. Screw the Swivel Assembly into the Body.

• Tighten the Swivel Assembly securely.

Transmission Fluid Filter

NOTE

: Refer to

Figure 5

for component iden-

tification.

1. Install Filter Tube (

26

) into Body (

25

).

2. Install O-Ring (

28

) onto Spring and Adapter Assembly

(

29

).

3. Install the small button of Stud (

27

) into the spring of the

Spring and Adapter Assembly.

4. Screw the Spring and Adapter Assembly into the Body.

• Tighten the Spring and Adapter Assembly securely.

Non-Drip Nozzle (Automatic w/ Manual Lock)

NOTE

: Refer to

Figure 3

for component iden-

tification.

1. Install Gasket (

22

) into Angle Body (

21

).

2. Install Washer (

23

) into Screw Assembly (

24

).

3. Thread the Screw Assembly into the Angle Body.

• Tighten the Screw Assembly securely.

4. Install O-Ring (

17

) onto Nozzle (

16

).

5. Install and seat V-Block (

18

) [concave first] onto the

pointed end of Stem (

19

).

6. Install the Stem assembly [point first] into the Nozzle.

7. Install Spring (

20

) into the Stem.

8. Screw the Nozzle assembly into Angle Body.

• Tighten the Nozzle securely.

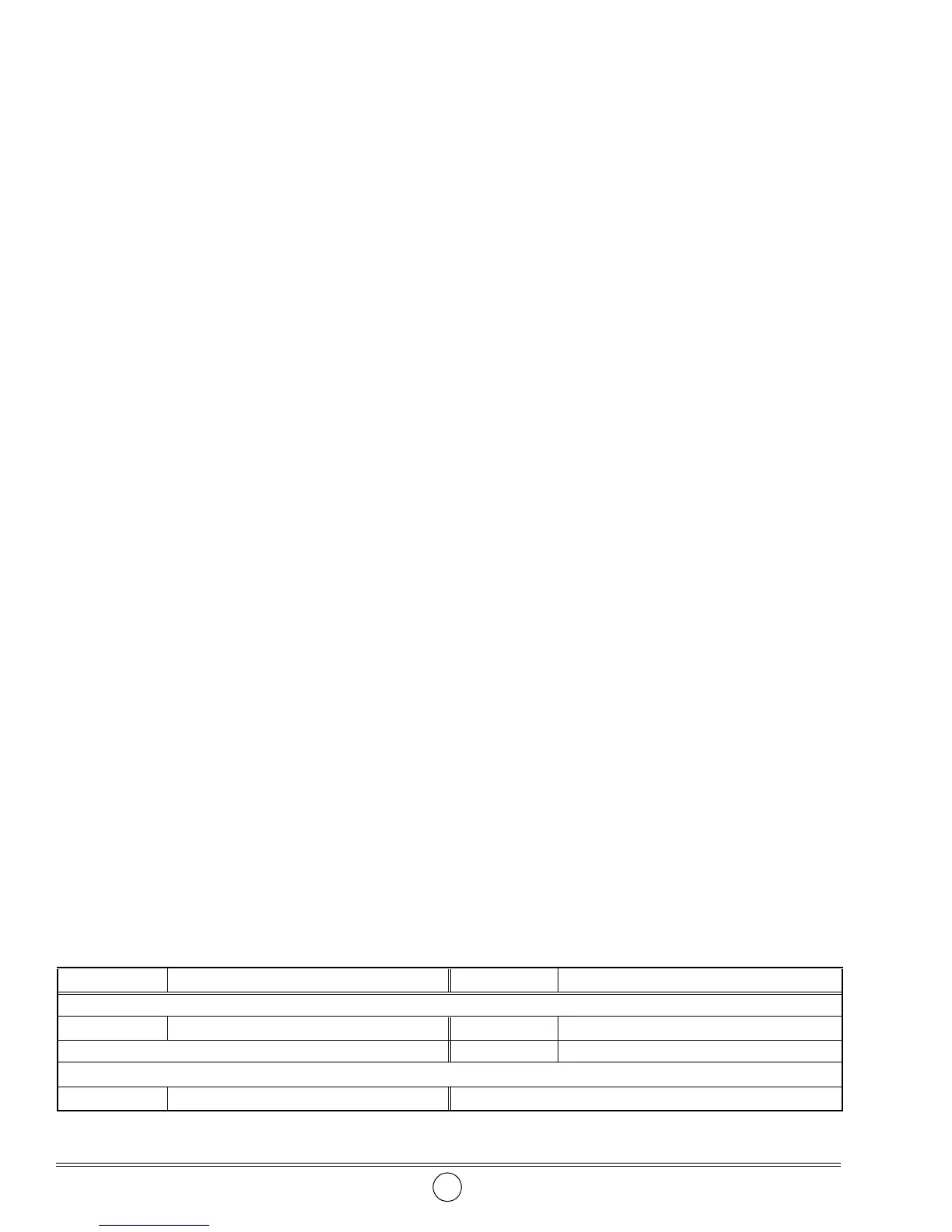

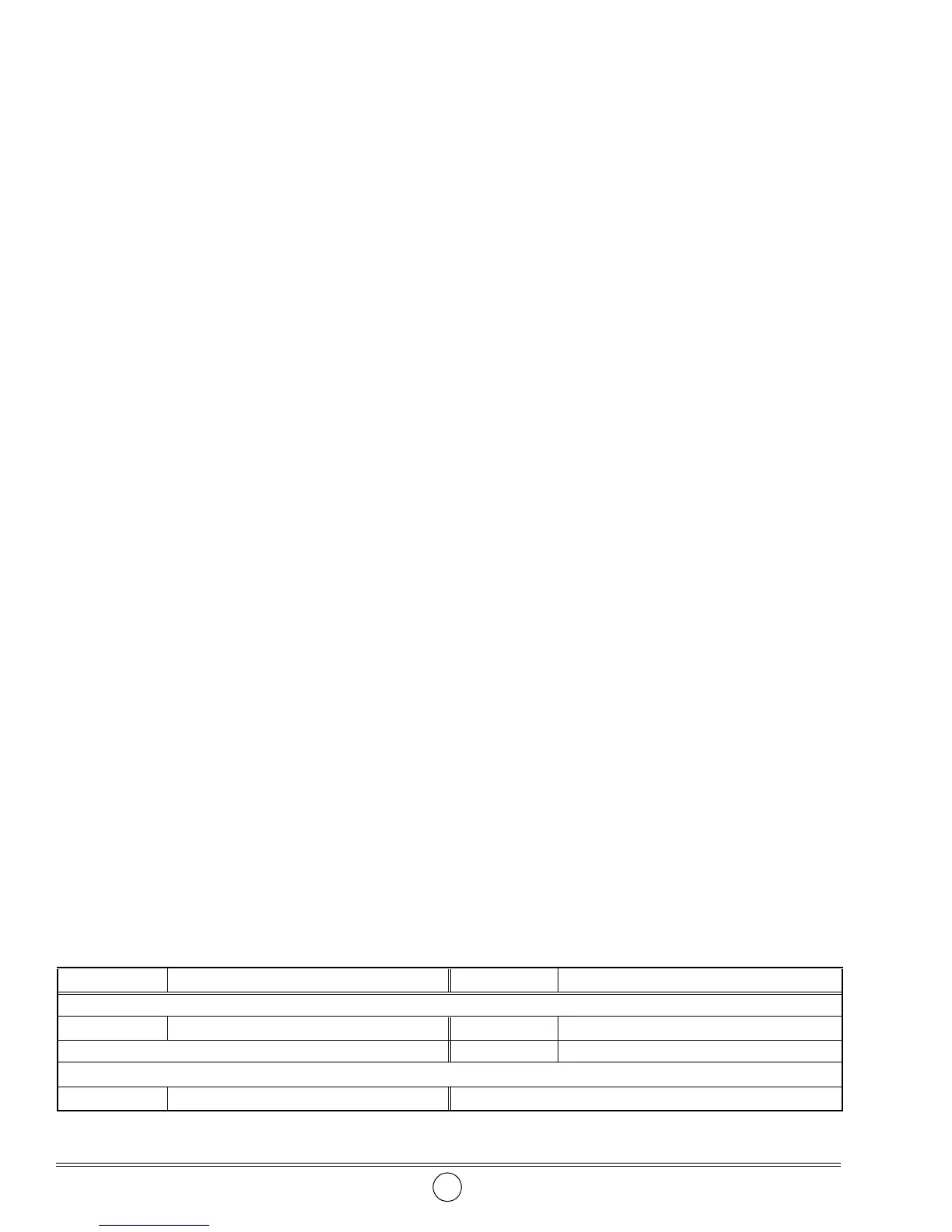

Item No. Description Item No. Description

Clean Oil

17 O-Ring, 1/2 " ID x 5/8 " OD 28

O-Ring, 3/4 " ID x 15/16 " OD

38 O-Ring, 13/16 " ID x 1 " OD

Multi-Purpose Grease

42 O-Ring, 1/2 " ID x 11/16 " OD

Table 2

Lubricated Components

1-800-548-1191-http://www.partdeal.com-info@partdeal.com

Loading...

Loading...