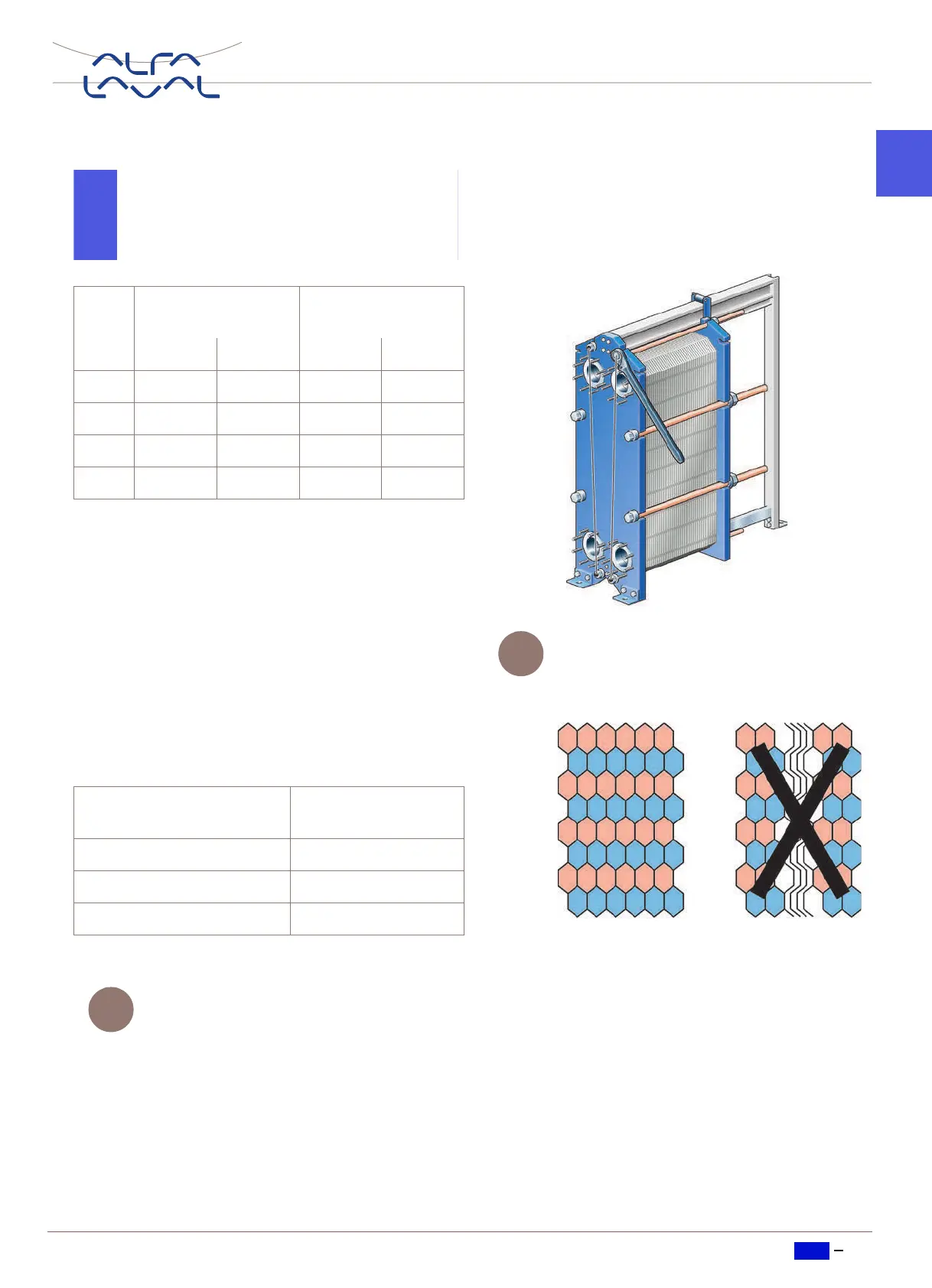

Maintenance English

Plate Heat Exchanger 15

eng

Max tightening torque

For manual tightening, the tightening torque has to

be estimated.

If dimension A cannot be reached

• Check the number of plates and the dimension A.

• Check that all the nuts and bearing boxes are

running freely. If not, clean and lubricate, or

replace.

The dimension A can be exceeded in exceptional

cases. The following plate package lengths could

then be accepted:

Place the other bolts in position.

• Inspect the washers.

• When fully tightened, the bolts should

all be equally tensioned.

• The difference between the plate pack-

age lengths (the dimension A) meas-

ured at adjacent bolts should not

exceed:

– 2 mm when A <1000 mm

– 4 mm when A >1000 mm.

• The plate package length at all bolts

must not differ more than 1 %.

• If the unit does not seal fully, it can be

tightened to give dimension A – 1 %.

The maximum tightening torque must

not, however, be exceeded.

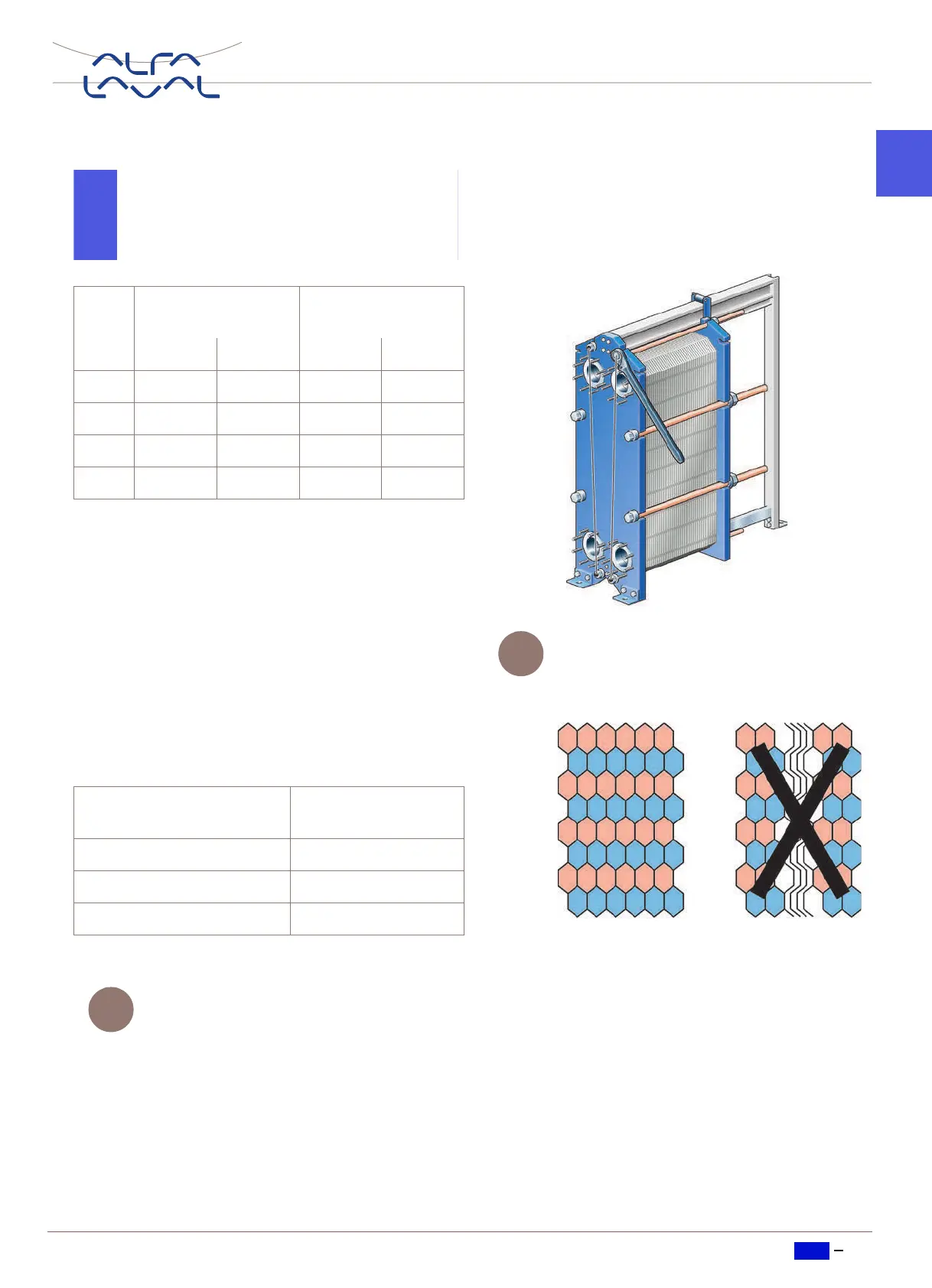

If the plates are correctly assembled, the

edges form a “honeycomb” pattern, see

picture below.

Bolt

size

Bolt with bearing

box

Bolt with washers

N·mkpmN·mkpm

M24 450 45

M30 900 90

M39 1300 130 2000 200

M48 2100 210 3300 330

Plate package length/plate Plate package

length (dimension A)

>4 mm A + 1 %

3–4 mm A + 1,5 %

<3 mm A + 2 %

Note!

When a pneumatic tightening device is used,

see table below for maximum torque. Meas-

ure dimension A during tightening.

Loading...

Loading...