Do you have a question about the Alfa Laval MBPX404 and is the answer not in the manual?

Details the content and purpose of the manual for the Alfa Laval separation system.

Outlines essential safety guidelines, including protective equipment requirements and immediate stop procedures.

Covers electrical, installation, maintenance, and operation safety rules.

Details system safety, vibration, hot surfaces, transportation, lifting, and drain/vent precautions.

Covers hazardous area, disintegration, entrapment, and burn hazards with associated safety measures.

Addresses corrosion hazards from cleaning agents and cut hazards from sharp components.

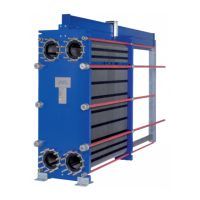

Provides general description of the separation system and specific details of the MBPX404 model.

Describes the function and components of the module for process and service liquid handling.

Explains the system's composition including control panel, pneumatic unit, and VFD for supervision.

Provides guidance on handling and inspecting the separator upon arrival, including shipping symbols.

Details procedures for safe unpacking, inspection for damage, and reporting missing items.

Outlines procedures for recycling packing materials and equipment, plus maintenance tasks.

Provides guidelines for storing the separator and precautions for its transportation.

Gives detailed instructions on safe lifting, using certified personnel, correct tools, and highlights mechanical/crush hazards.

Outlines requirements for mechanical installation, including space planning, authorized personnel, and local regulations.

Details requirements for electrical installation, emphasizing authorized personnel, local legislation, and EU guidelines.

Describes cleaning methods, agents, and warnings for electrical and disintegration hazards during cleaning.

Covers installation checks for auxiliary equipment like valve modules and pneumatic units, focusing on safety and connections.

Lists prerequisites for commissioning, including service, mechanical completion verification, and pre-commissioning checks.

Outlines final checks required before start-up, covering connections, grounding, electrical, valves, and system pressures.

Presents a diagram of the main operating sequence transitions and modes.

Explains the system's state upon power-on and the start-up process, including bowl rotation.

Details the functions of Standby, Production, CIP, and Stop operational modes.

Explains the emergency stop function, deactivating motor contactors and entering a safe state.

Step-by-step guide for powering on the system and setting it to Stand Still mode, including initial checks.

Details steps to initiate START, check resources, and the automatic transition to STANDBY.

Outlines manual discharge from STANDBY and notes on overheating hazards.

Explains how to select PRODUCTION mode, feed process, and manage concentrate discharge.

Describes the steps to select CIP mode, feed product, and manage concentrate discharge during cleaning.

Details how to select STOP, turn off the motor, apply brake, and transition to STAND STILL.

Outlines steps for activating emergency stop, acknowledging alarms, and resetting the system.

Describes the operator interface's process screen, its header, rows, and functional buttons.

Explains how to adjust process and system parameters, including login requirements and value limits.

Describes the I/O screen for viewing digital and analog input/output status, referencing the technical documentation.

Details how to set discharge time intervals, volume, and initiation logic based on time or turbidity.

Covers system information display, user access levels, alarms, and runtime administration functions.

Explains the current log screen, which displays the last ten current peaks during discharge cycles.

Describes how to view trend diagrams for current, speed, backpressure, and flow control.

Details the flow control screen, PID adjustments, and modes like Auto, Manual, and OPEN.

Explains the backpressure control screen, PID adjustments, and modes like Auto, Manual, and OPEN.

Describes the output test feature for checking system output signals individually via manual commands.

Explains current monitoring for discharge performance and bowl integrity, including breakdown hazards.

Details how the control system uses parameters to calculate control values for the VFD to manage bowl speed.

Guides on how to acknowledge new and existing alarms, reset signals, and the implications for alarm lamps.

Explains how to read the alarm diagram, understand codes, interlocks, start blocking, and overrides.

Lists and describes various VFD parameters for the separator, including default and used values.

Details speed converter settings and lists user roles with their corresponding passwords for system access.

Specifies the information required when ordering spare parts, such as machine number and article number.

Provides information on contacting Alfa Laval representatives for assistance, questions, or service requirements.

| Brand | Alfa Laval |

|---|---|

| Model | MBPX404 |

| Category | Industrial Equipment |

| Language | English |