Do you have a question about the Alfa Laval PHE and is the answer not in the manual?

Essential safety guidelines and user responsibilities for safe operation and maintenance.

Details on warranty terms, coverage, and procedures for claims or issues.

Information on definitions, drawings, and general advice for using the PHE.

Guidelines for storing the Plate Heat Exchanger in an indoor environment.

Precautions and checks required for outdoor storage of the unit.

Procedures to ensure proper function after the PHE has been stored for over a year.

Guidelines for recycling or disposing of packing materials.

Procedures for recycling metal parts and handling non-metal wear parts.

Regulations and methods for recycling equipment at end-of-use.

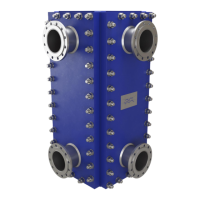

Identification and basic function of the primary parts of the Plate Heat Exchanger.

Details found on the unit's name plate, including specifications and warnings.

Explanation of how heat is transferred between fluids within the PHE.

How to configure the PHE for heating and cooling stages using connection plates.

Creating multi-pass sections by using turning plates for flow direction control.

How to identify different plate types using markings like -1 and -2.

Essential checks and considerations before connecting the PHE to the system.

Requirements for a stable foundation and adequate space for installation and maintenance.

Instructions and warnings for safely lifting the PHE using straps and a hook.

Step-by-step instructions for mounting the support stands onto the PHE.

Steps to ensure safe and correct start-up of the Plate Heat Exchanger.

Checks to perform during normal operation to maintain performance and safety.

Safe steps for shutting down the PHE, including draining and rinsing if necessary.

Procedures for cleaning the fluid-contacting surfaces of the PHE.

Recommended methods for sterilising the PHE before the next production cycle.

Specific cleaning routines for products with high protein content.

Cleaning procedures for products like beer and wine with low insoluble components.

Description of various cleaning agents used in Cleaning-In-Place (CIP) systems.

Information on selecting appropriate CIP equipment for cleaning.

Considerations for using chlorine and its effect on stainless steel.

Step-by-step guide for safely opening the PHE for maintenance or inspection.

Method for cleaning deposits using water and a soft brush without removing plates.

Instructions for correctly reassembling the PHE after maintenance.

Procedure for performing a pressure test to confirm sealing after repairs or gasket changes.

Detailed instructions for replacing gaskets on the PHE plates.

| Type | Plate Heat Exchanger (PHE) |

|---|---|

| Plate Material | Stainless steel, titanium, nickel |

| Gasket Material | Nitrile, EPDM, Viton |

| Frame Material | Carbon Steel, Stainless Steel |

| Operating Pressure | Up to 25 bar (varies by model) |

| Flow Rate | Varies by model and application |

| Plate Thickness | 0.4 mm to 0.8 mm (varies by material and model) |

| Connections | Flanged, Threaded (depending on model) |

Loading...

Loading...