Scheduled maintenance intervals for Gamajet tank cleaning

The Alfa Laval Gamajet should be washed out with clean water after each use to remove any foreign material or soft substances

left in the machine that may har

den during storage and cause the Alfa Laval Gamajet to seize or lock up. A clean water rinse

through the Alfa Laval Gamajet will also wash out any residues of chemical cleaners or recirculated wash water that could

adversely affect the O-rings during prolonged contact in storage.

The best position to store the machine is to stand it up with the inlet connection facing down. This preventive maintenance

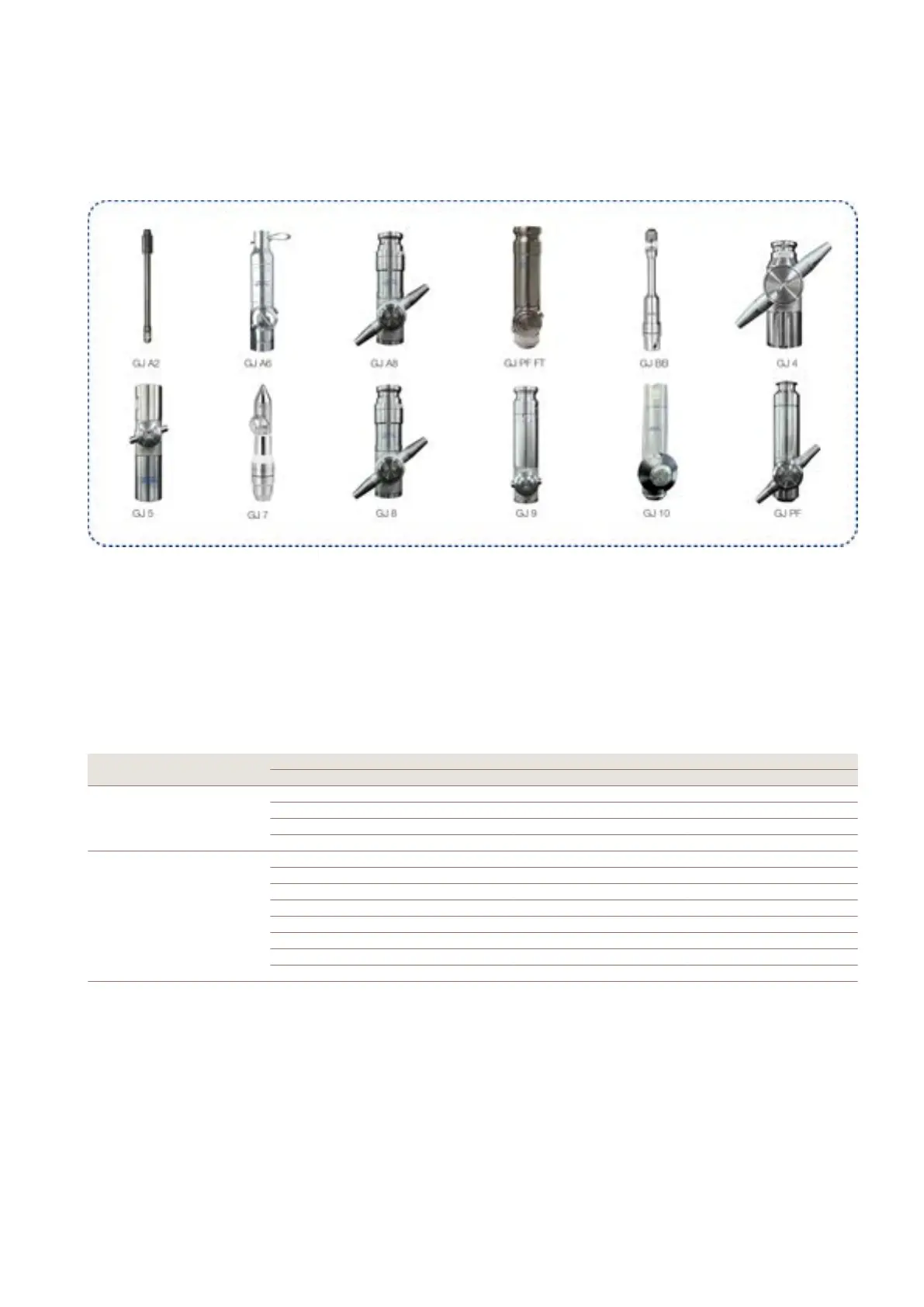

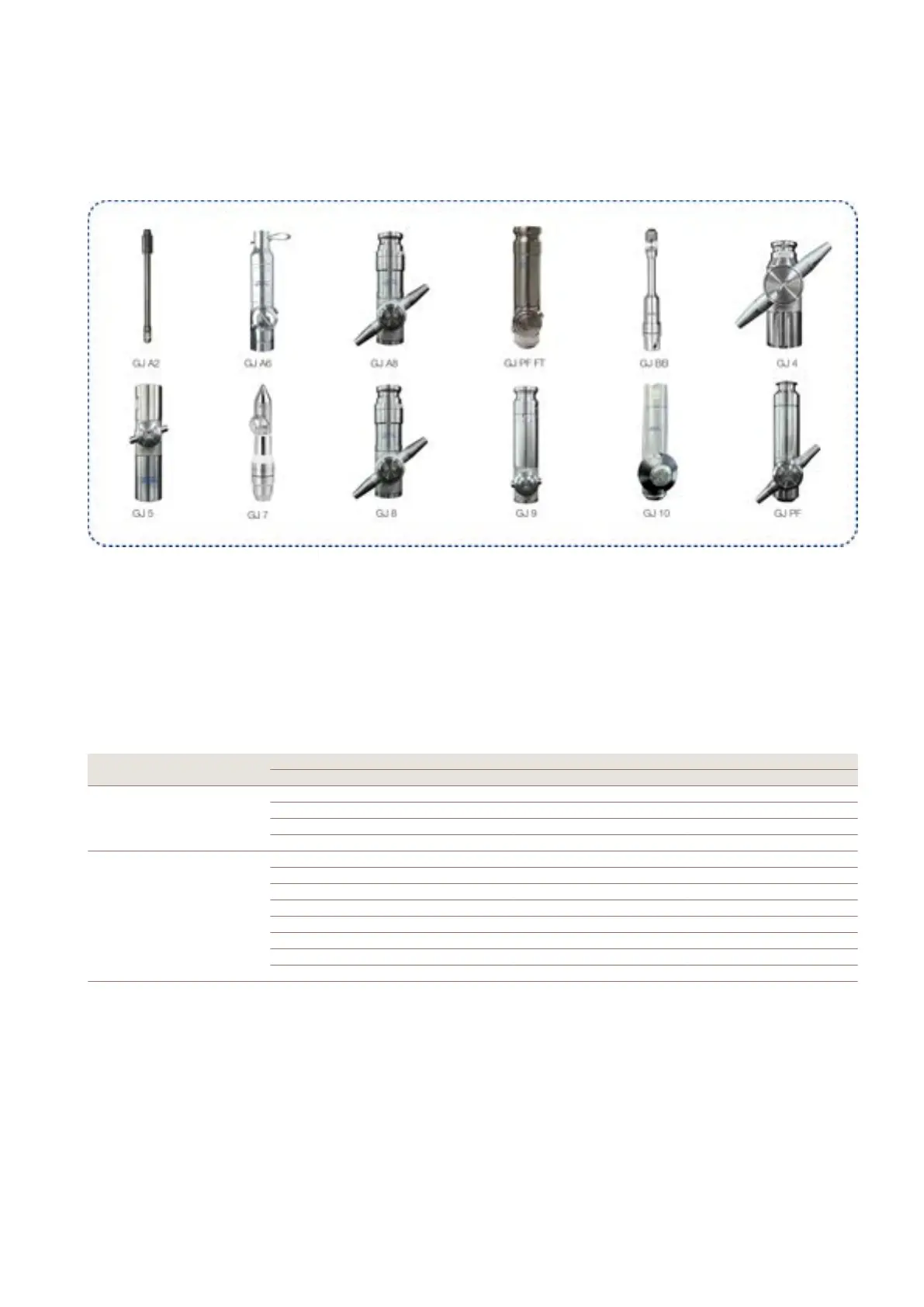

guidelines cover Gamajet rotary jet heads:

An interval of 100 hours is recommended initially

. If all of the components are found to be in acceptable condition after the first

100 hours, the Alfa Laval Gamajet may then be inspected and routine preventive maintenance should be performed

recommended hours of operation, depending on the severity of use.

All the bearings, bushings, seals and O-rings are wear parts. Ideally, they should all be replaced, as a group, If just one bearing

or seal is worn or damaged, replace both it and its mate, not just the worn or damaged part. Gamajet recommended

maintenance hours shown as below:

Application

Replace service kit every x working hours or y years:

Type 100 hours 100–200 h 300–500 h 400–600 h 500–700 h 600–800 h

Food, Dairy & Beverage

GJ A2 X X

GJ A6 X X

GJ A8 X X X

GJ PF FT X X

Fine chemical & industry

GJ BB X X

GJ 4 X X

GJ 5 X X

GJ 7 X X

GJ 8 X X

GJ 9 X X

GJ 10 X X

GJ PF X X

All recommended service kits are found in the manual for the specific machine.

The above guidelines may not apply in all working conditions.

Please contact Alfa Laval for information relating to specific applications.

Loading...

Loading...