Example of exploded view - Unique Mixproof

Cut-away views of

the plug and seat

design in Unique

mixproof valves.

Closed Open

Cover

Flushing tube

with o-ring

Lip seal

O-ring

Lower

valve plug

Seal ring

Clamp ring

Valve body

PTFE guide ring

PTFE

guide ring

Upper

valve plug

Upper sealing

element

Lip seal

O-ring

Clamp ring

Spray

nozzle

(spiral clean)

O-ring

O-ring

Lock

Clamp

Flushing tube

with o-ring

Spindle liner

Clamp

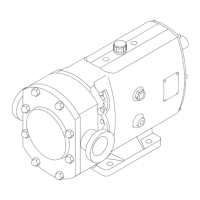

Actuator

Nozzle

Drain

Lower sealing

element

Inspect the valves regularly

The Alfa Laval valves are available in various con figurations to fit speci fic applications. To inspect the valves you need to know

the type of valves and which seals ar

e used. This information can be obtained online by using the serial number no which along

with year of manufacturing is laser marked on to the actuator. Preventive maintenance aims to prevent failure of equipment by

doing e.g. regular inspection of seals, lubrication and/or adjustments of surrounding equipment without prior knowledge of

equipment failure. Based on experience and knowledge about the running conditions, it is also possible to replace wear parts

before they fail. Keeping a record of the valve is a good way to build experience for inspection planning.

This Preventive Maintenance Guideline is applicable to most types of valves. Below are show some examples:

Mixproof valves Single seat valves

Buttery valves

Regulating valves

Ball valves Safety

valves

Sample

valves

Shutter

valves

Diaphragm

valves

Unique

Mixproof

SMP-BCAseptic

Mixproof

Unique

Mixproof

Tank Outlet

Unique

SSV

Unique SSV

Tank Outlet

LKAP

Air-Operated

LKB

LKB

UltraPure

LKB-F

Unique

RV-ST

Unique

RV-P

CPM-2 SBV Sanitary Unique Sampling

Valve

MH Shutter Unique DV-ST

UltraPure

Safety Valve

Suggested scheduled maintenance intervals

Several factors in fluence the maintenance cycle. The number of activations is important but even with few activations the rubber

materials will harden over time and need replacement. The time depends on the product contents, concentration and type of

CIP, SIP, differential pressure and processing temperatures. To ensure that your valves operate efficiently, it is essential to follow a

simple preventive maintenance programme. Good maintenance requires careful attention at regular intervals. For lubrication

please always refer to the manual for specific information on oil/grease types and required maintenance. Alfa Laval recommend:

• Always carefully follow the instruction manual for the speci fic valve.

• Lubricate relevant rubber parts with the lubricant supplied with the service kit before fitting.

• Service kit for valves actuator parts: Replace after 5 years or depending on working conditions.

• Service kit for valves product wetted parts: Replace every 12 months or depending on working conditions.

• Service kit for Unique sampling valves: Replace after 500-1000 samples depending on working conditions

The guidelines may not apply in all working conditions. Please contact Alfa Laval for information relating to specific applications.

Loading...

Loading...