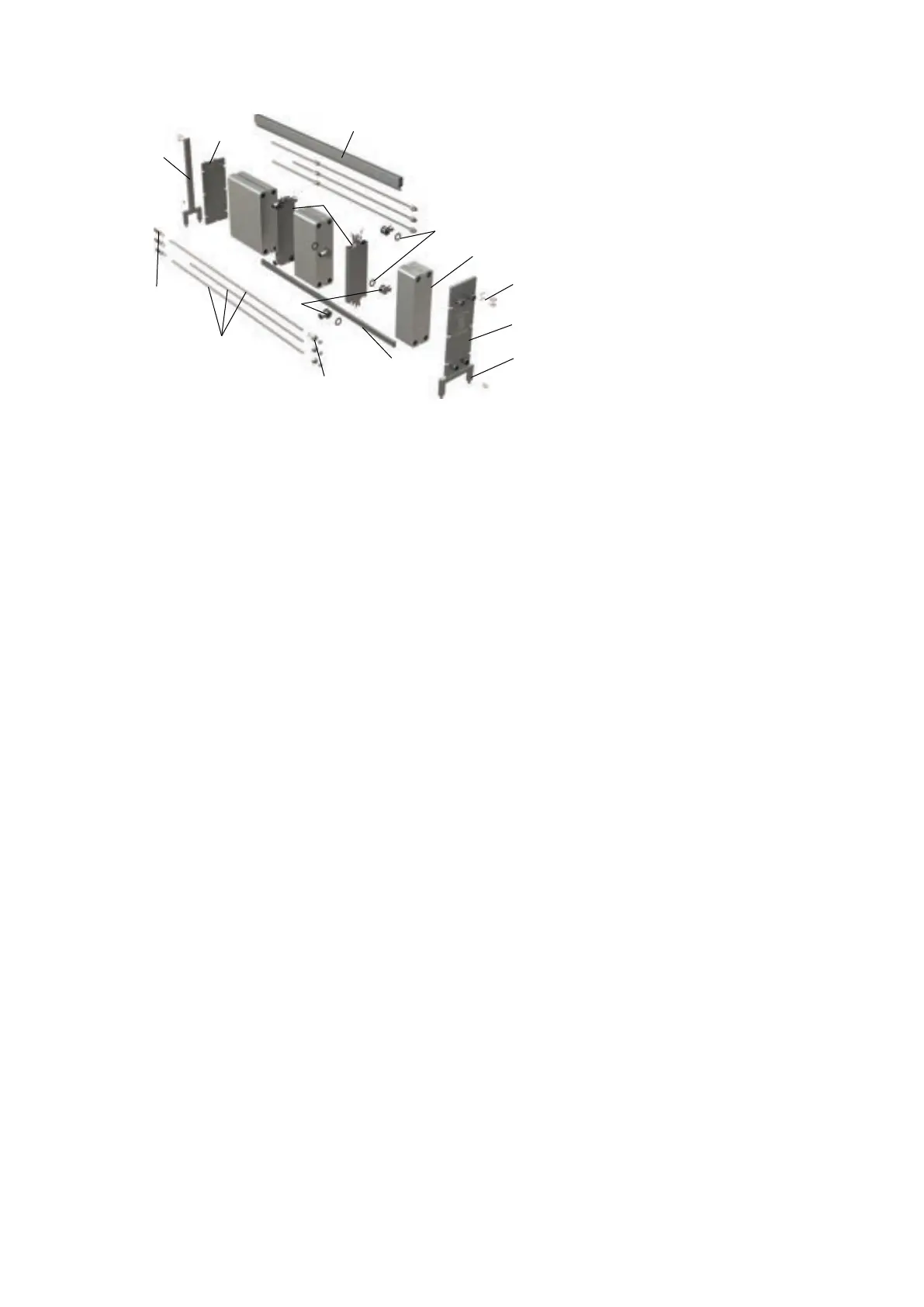

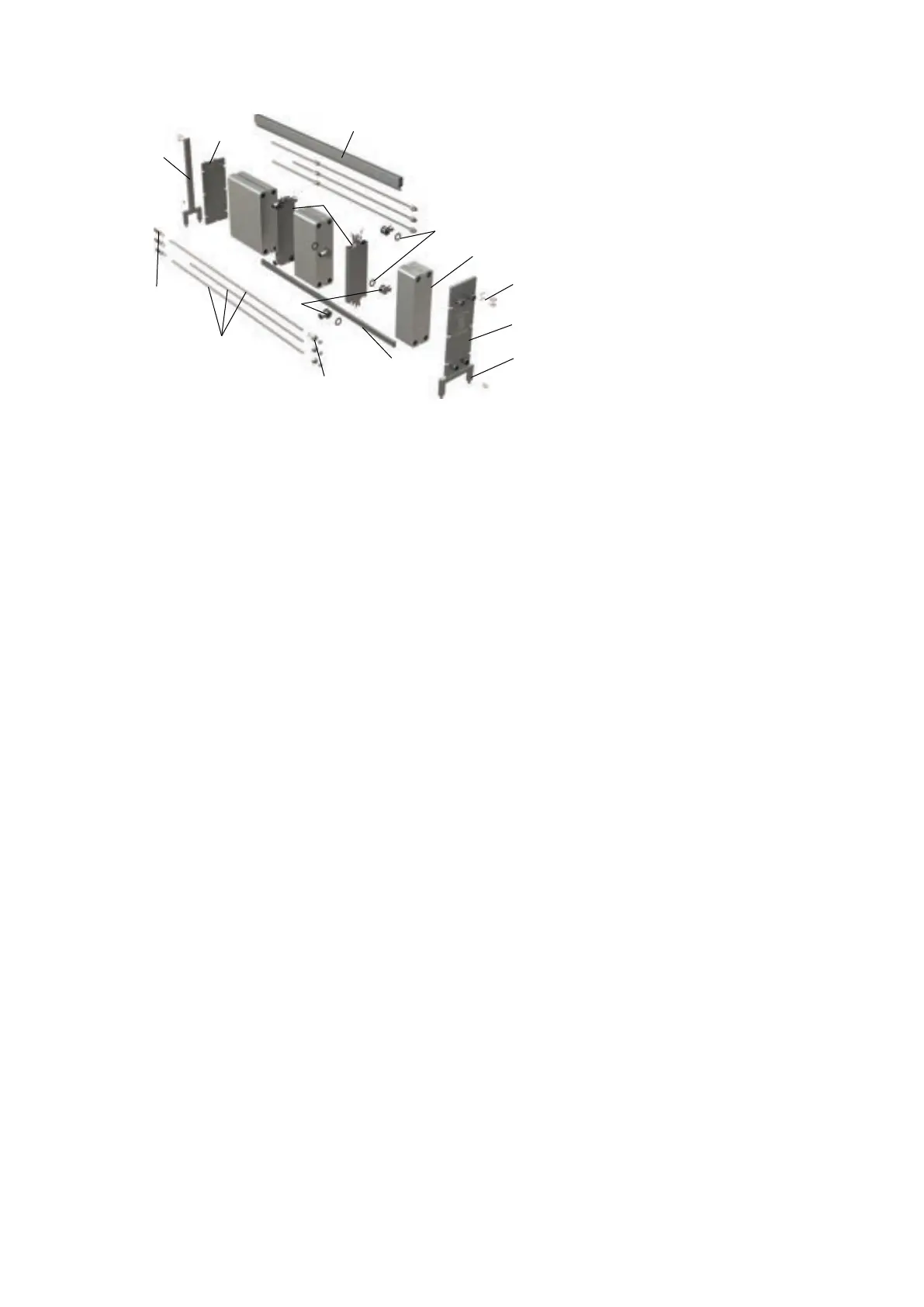

Example of explodede view — Front 8

Support column

Pressure

plate

Carrying bar

Conne

ction plat

e

Ring gasket

Plate pack

Washer/screw

Frame plate

Foot

Guiding bar

Bearing box/lock washer

Tightening bolt

Nut/washer

Corner

Factors effecting efficiency and lifetime

Maintaining heat transfer and sealing ef

ficiencies is vital to pr

oductivity

. Frequent cleaning on regular basis ensures heat transfer

efficiency as well as prevents the buildup of residual material on the plates. Barring the presence of corrosive media, clean plates

effectively limit other factors that may contribute to gasket wear.

A gasket, its material properties and its construction are specifically selected to provide optimal sealing performance for its

intended application. Knowing exactly when to replace gaskets is difficult since the timing varies, depending on the application

But over time, all gaskets wear due to natural aging as well as the temperature, pressure and stress of normal operating

conditions. In extreme cases, gaskets are also subject to blowout due to pressure shock in the system that may damage the

plates. Even despite best practices, leakage can occur.

• Compression

Gaskets are subjected to local stress from the moment you first clip them on to and tighten the plates. Subsequent opening

and closing of any heat exchanger also puts undue stress on the gaskets, causing loss of elasticity and sealing ability. To

prevent unnecessary wear, automatic cleaning procedures, such as cleaning in place (CIP), are recommended

• Cleaning in place

Carefully monitor your cleaning process since the composition of the cleaning solution can, over time, affect the rubber.

Always use the cleaning solutions recommended by your gasket supplier since using substitutes can harm the gaskets.

Some cleaning solution suppliers, for instance, add ozone to the water, which degrades the rubber in gaskets used in

sterilisation processes

• Temperature

Higher operating temperatures cause more wear and tear on the gaskets. So do the temperature swings from hot to cold

that are characteristic of dairy and other sanitary processes. Under these conditions, leakage may occur. Careful monitoring

is key to early detection. Whenever cold leakage occurs, especially at startup, it is time to replace the gaskets

• Pressure

Higher pressure also causes more wear and tear on the gaskets. Therefore, processes operating at higher pressures

generally require more frequent gasket replacement. That’s why plate heat exchangers used to pasteurise beer, for example

require gasket replacement more often than those used for dairy pasteurisation.

Loading...

Loading...