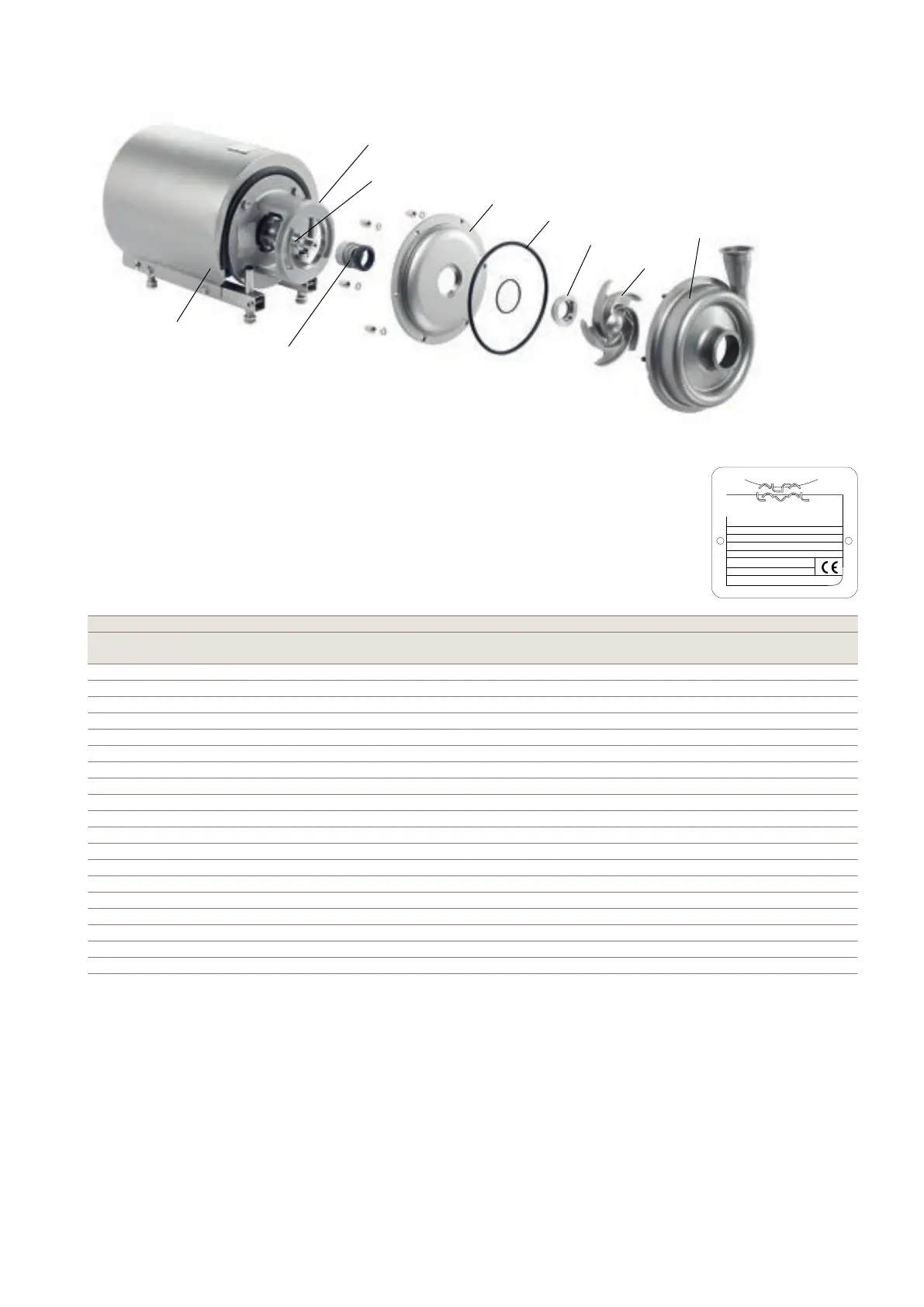

Example of exploded view - LKH Pumps

Motor adaptor

Compression ring

Back plate

Casing O-ring

Stationary seal

Rotating seal

Motor and shroud

Impeller

Casing

Inspect the pump regularly

The Alfa Laval pumps are available in various configurations to fit specific applications. To inspect the

pump you need to know the type of pump and which type of seal is used. This information is available

on the name plate of your pump. Further information can be obtained online by using the serial number.

Preventive maintenance aims to prevent failur

e of equipment by doing e.g. regular inspection and

lubrication.Based on experience and knowledge about the running conditions it is also possible to

replace wear parts before they fail. Keeping a maintenance log is a good way to build experience.

Pump Type

Serial No.

Alfa Laval, Albuen 31, Kolding, DK-6000

LKH-20

Specification

123456

Year 2017

163 11.0kW 50Hz SSS

Manufacturer:

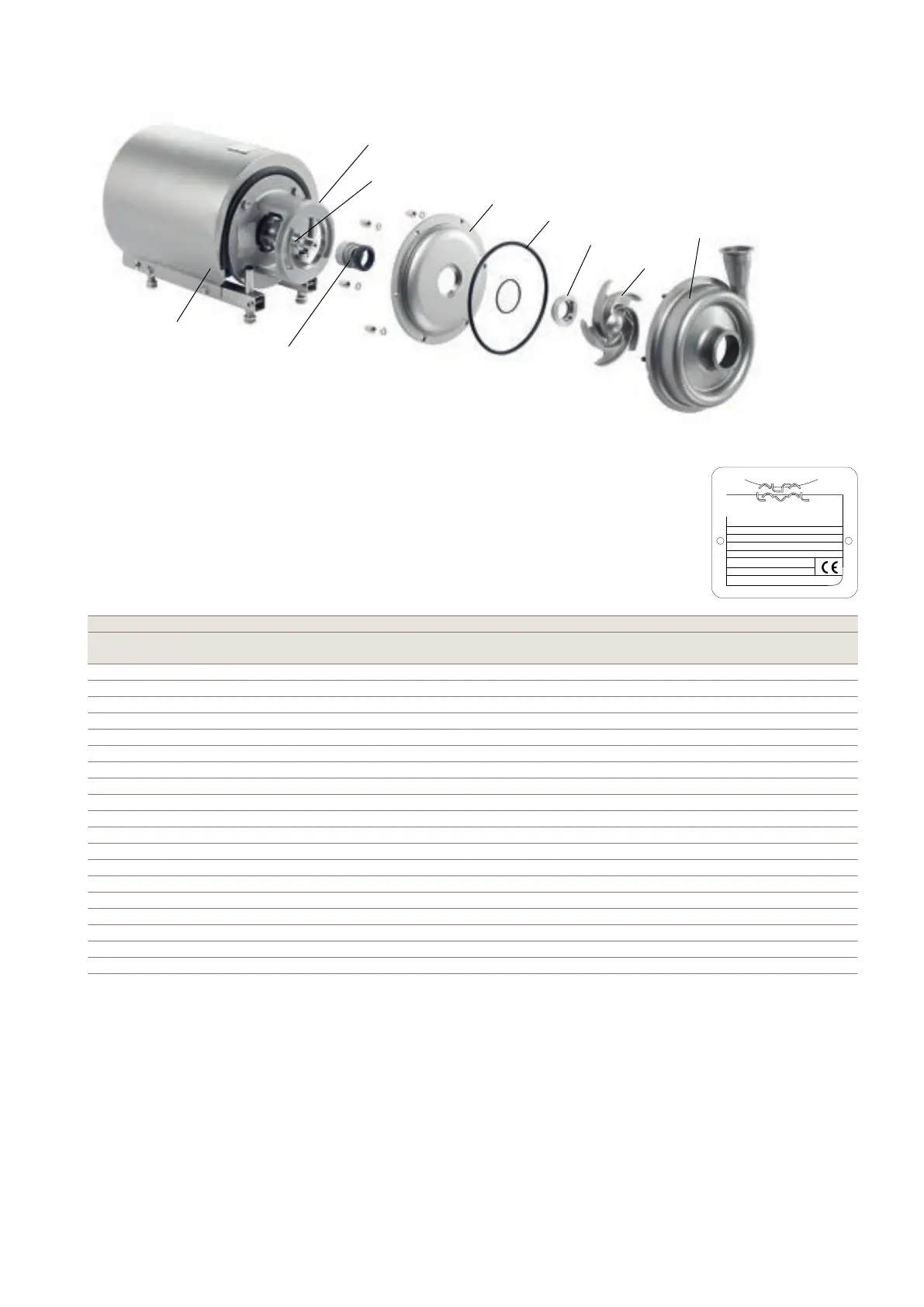

Keep a record of the pump, use the statistics for inspection planning Inspect / Clean / Lubricate

LKH, LKH Evap, LKHI, LKHPF, LKHM, LKHex, SolidC, i-CP, FM-OS, GM,

LKH Prime, MR

Supplier

instruction

Weekly Monthly Half-yearly

Over all pump

Keep pump clean and protected from environment X

Listen for unusual noise X

Keep a record of the pump X

Use the statistics for inspection planning

Shaft seal

Inspection for leakage (* SSS; FSS; DMSS/DSS) X

Flow rate of flushing (* FSS, DMSS/DSS) X

Motor

X

Motor surface temperature X

Bearing temperatures X

Bearing vibration X

Inspection Motor bearings X

Pump head

Check pump head and flow rate X

Check for internal wear and pitting X

* SSS=Single shaft seal, FSS= Flushed single shaft seal, DMSS/DSS= Double mechanical shaft seal.

** During r

eplacing shaft seals, service kit contains all necessary parts.

Scheduled maintenance intervals

T

o ensur

e that your pumps operate ef

ficiently, it is essential to follow a simple preventive maintenance programme, which will

keep your machine in good working condition. Good maintenance requires careful attention at regular intervals. For pump

lubrication please always refer to the manual for specific information on oil/grease types and required maintenance. Alfa Laval

recommend:

• Service kit should be replaced after 12 months. Always replace shaft seal and o-rings at the same time.

• Inspect motor bearings yearly, replace complete bearing if worn, ensure that the bearing is axially locked (See motor

instructions)

Loading...

Loading...