4Operation

Pay attention to possible faults. Study the instructions carefully.

The items refer to the parts list and service kits section.

4.2 Troubleshooting

NOTE!

Study the maintenance instructions carefully before replacing worn parts - section 5.1 General maintenance.

Problem

Cause/result

Repair

External product leakage Worn or damaged lip

seal and/or O-rin

g

- Replace the seals

- Replace with seals of a

different rubber grade

Internal product leakage - Worn or product-affected

plug seal

- Replace the seal

- Replace with a seal of a

different rubber grade

- Product deposits on

the seat and/or plug

- Frequent cleaning

Water hammer The flow direc

tion is the

same as the closing direction

-Theflowdirec

tion should be

against the cl

osing direction

-Throttleair

release of solenoid in

top unit

4.3 Recommended cleaning

Step 1

Always handle lye and acid with great care.

Caustic danger!

Always use

rubber gloves!

Always use

protective goggles!

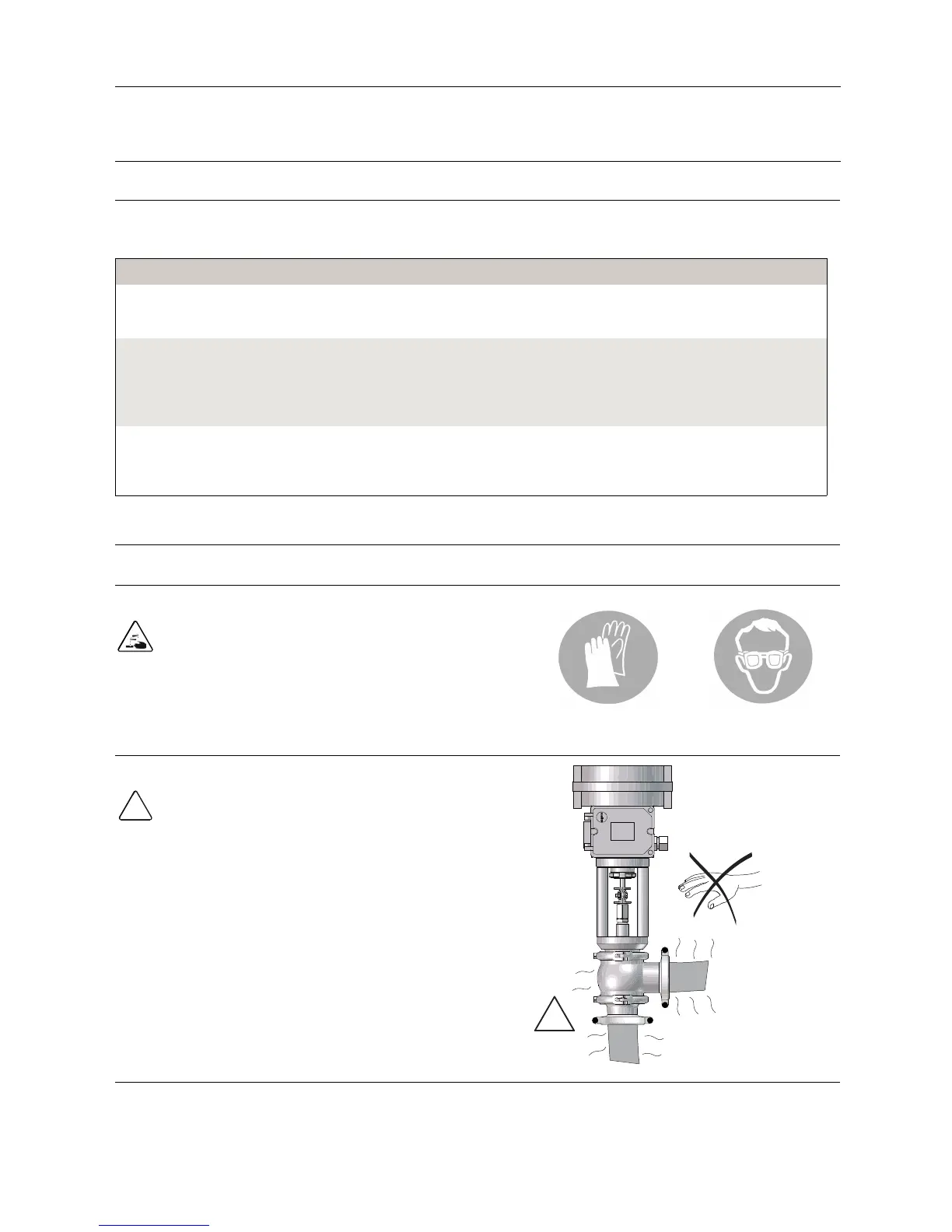

Step 2

!

Never touch the valve or the pipelines when sterilising.

Danger of burns!

2405-0011

!

16

Loading...

Loading...