5 Maintenance

Maintain the valve regularly.

Study the instructions carefully and pay special attention to the warnings!

Always keep spare rubber seals and lip seals in stock. Always use Alfa Laval genuine spare parts.

Check the valve for smooth operation after service.

Step 4

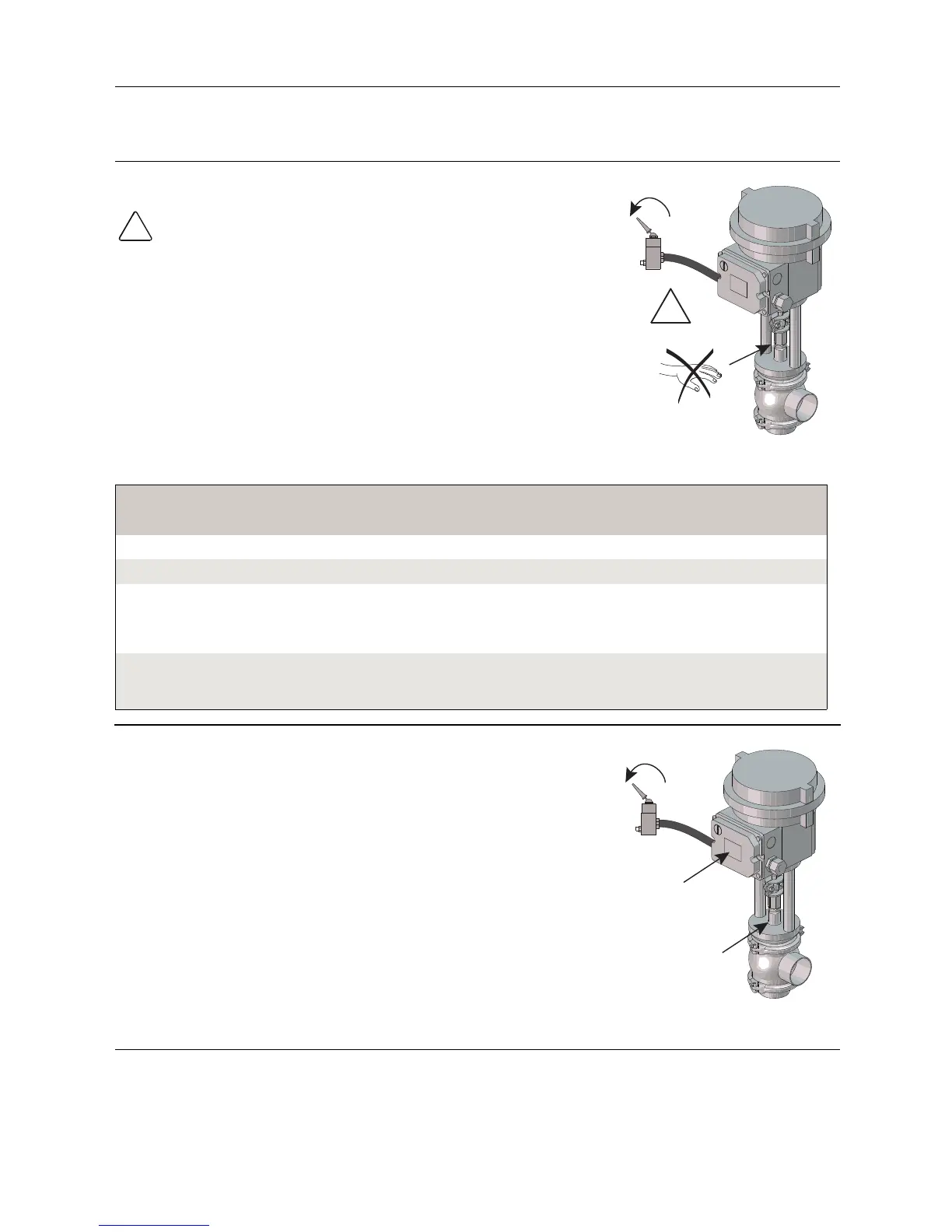

!

Never touch the moving parts if the actuator is supplied with

compressed air.

Moving parts!

2405-0005

!

Below are some guidelines for maintenance and lubrication intervals.

Please note that the guidelines are for normal working conditions in one shift.

Product wetted seals

Preventive maintenance

Replace after 12 months depending on working conditions

Maintenance after leakage (leakage normally starts slowly) Replace at the end of the day

Planned maintenance

- Regular inspection for leakage and smooth operation

- Keep a record of the valve

- Use the statistics for inspection planning

Replace after leakage

Lubrication

Before fitting

Klüber Paraliq GTE 703 or similar USDA H1 approved

oil/grease

Pre-use check:

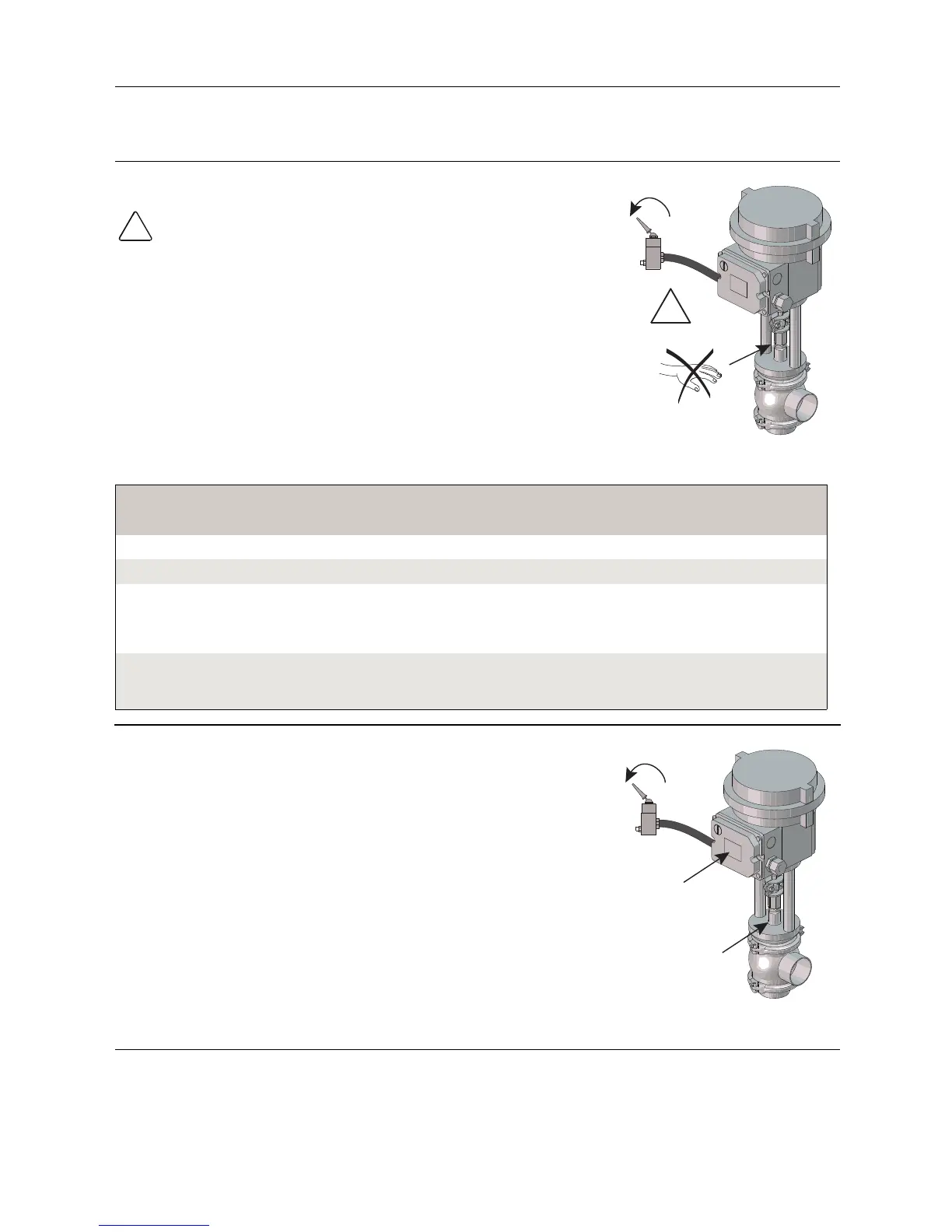

1. Supply compressed air to the actuator.

2. Activate the positioner program P15 to initialise the positioner.

Pay special attention to the warnings!

2405-0017

19

Loading...

Loading...