8

1 • GENERAL WARNINGS

• The oven must be part of an equipotential bonding system.

This connection is made by attaching a conductor with a

nominal section of up to 10 mm2 to the specific terminal,

located on the rear of the oven, marked with the international

symbol IEC60417 – 5021.

The connection is made between all the adjacent devices in

the room and the dispersion system in the building.

• This device is for use up to an altitude of 2000m above sea

level. For installations at altitudes over 2000m above sea

level., please contact an authorised technical service centre.

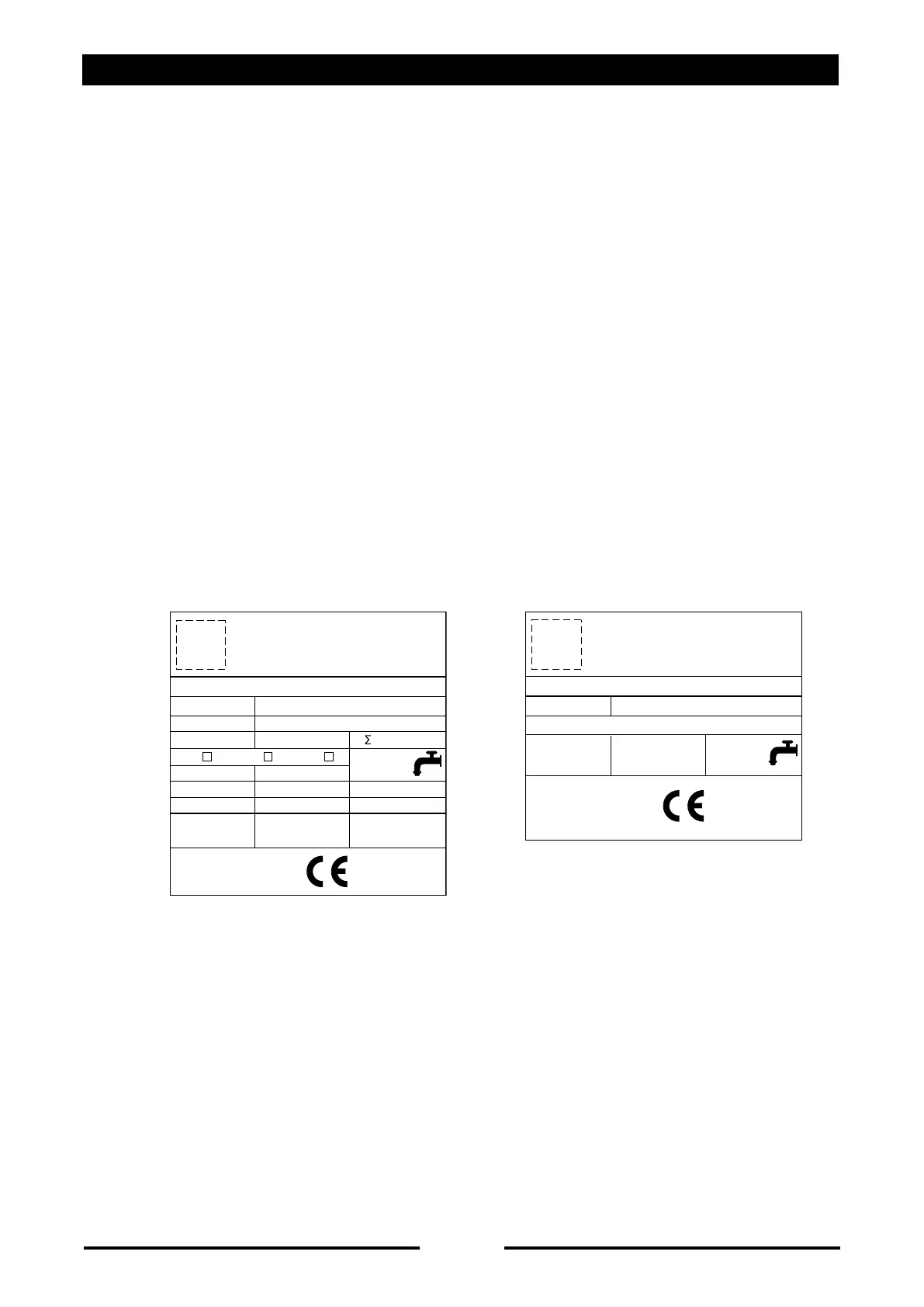

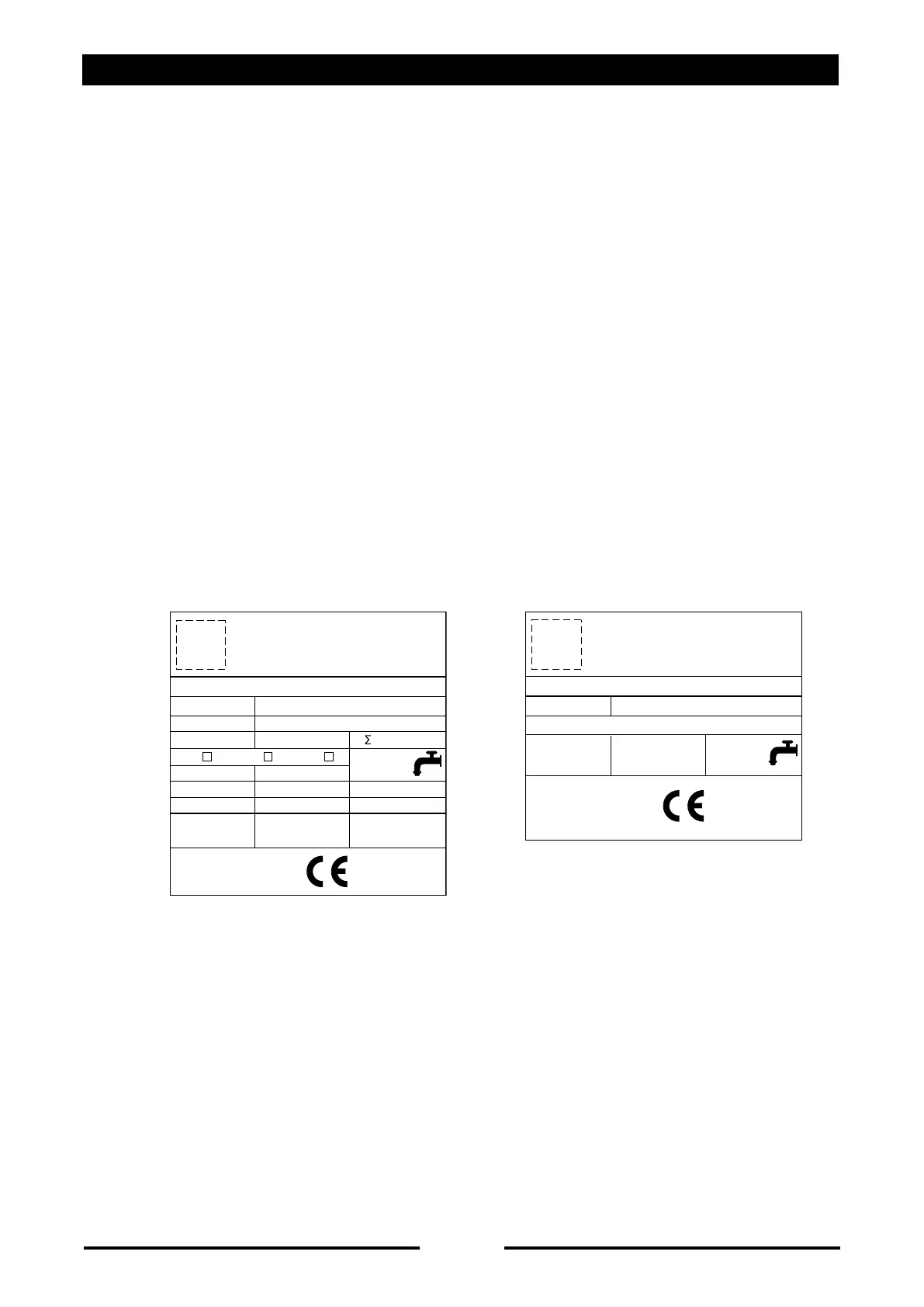

• Each oven is equipped with an ID plate that states the oven

model and its main technical features. Following is an example

of an electric oven plate and a gas oven plate.

• These appliances are intended to be used for commercial

applications, for example in kitchens of restaurants, canteens,

hospitals and in commercial enterprises such as bakeries,

butcheries, etc., but not for continuous mass production of

food.”

• This manual is also available in an electronic format.

Contact your help service.

0085

2010

EN 203/A1 AC 230V 50Hz

IT

IPX 5

G 25 / m

3

/h

Qn 40 kW

Cat.

II 2H3+

NR XXXXXXXXXX

kPa

200 - 500

P mbar

20; 28-30/37

TOT 1 kW1 x 0.55 kW

G 20 / m

3

/h

G 30 3.16 Kg/h

Pmax / mbar Pmax / mbar

Pmin / mbar Pmin / mbar Pmin / mbar

A3 B13 B23

2010

3N AC 400V 50Hz

IPX 5

NR XXXXXXXXXX

kPa

200 - 500

TOT 6.25 kW1 x 0.25 kW

TYP. XXXXXXXX

LOGO

0085

2010

EN 203/A1 AC 230V 50Hz

IT

IPX 5

G 25 / m

3

/h

Qn 40 kW

Cat.

II 2H3+

NR XXXXXXXXXX

kPa

200 - 500

P mbar

20; 28-30/37

TOT 1 kW1 x 0.55 kW

G 20 / m

3

/h

G 30 3.16 Kg/h

Pmax / mbar Pmax / mbar

Pmin / mbar Pmin / mbar Pmin / mbar

A3 B13 B23

2010

3N AC 400V 50Hz

IPX 5

NR XXXXXXXXXX

kPa

200 - 500

TOT 6.25 kW1 x 0.25 kW

TYP. XXXXXXXX

LOGO

90036450rev01

Loading...

Loading...