Malfunctions Not Indicated by a Fault 3-11

Encoder Device Malfunction

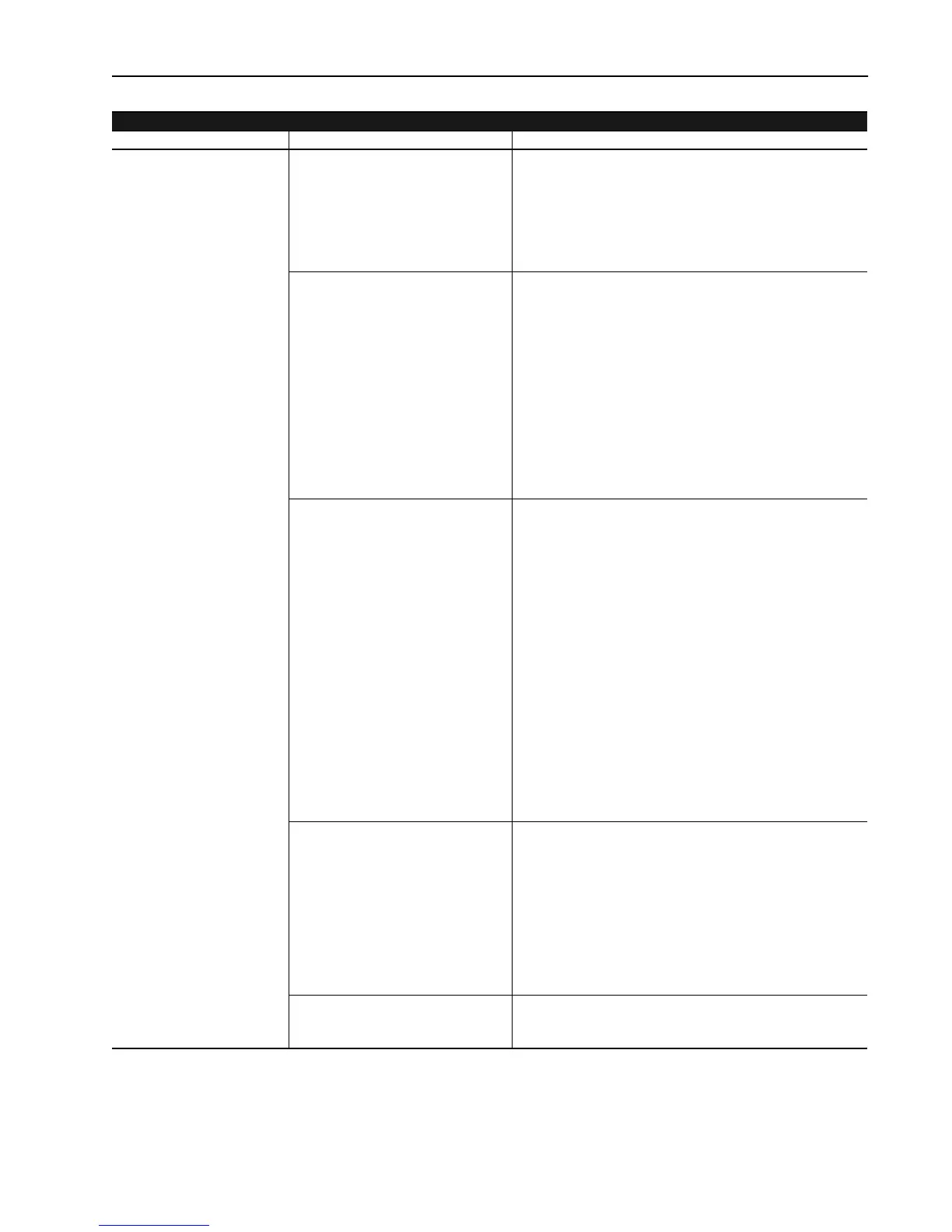

Malfunction Symptom Solution

The drive faults on “VP-10

Feedback Loss”. This indicates

that the measured velocity from

the encoder is less than the

level programmed in parameter

732 “Tach Loss Vel” and the

velocity calculated from the

CEMF of the motor is greater

than the level programmed in

parameter 731 “Tach Loss

CEMF”.

The velocity feedback is not being

registered because jumpers on the Main

Control Board are selected incorrectly

for the encoder in use. Verify that the

jumper selection for the encoder output

voltage on the Main Control Board is

correct.

• For 5V differential encoders J8, J9, and J10 should be in

position 1-2. For 12V differential encoders J8-J10 should be in

position 2-3.

The encoder feedback device is

inoperative due to lack of encoder power

supply. Measure the encoder power

supply from the 1395 drive by measuring

from TB3-13 (+) to TB3-14 (-) with a

DVM. The voltage level should be +12V,

10%.

• If the supply is near zero remove all power to the drive.

Disconnect the encoder supply connections at TB3-13 and

TB3-14. Apply power and repeat the measurement. If the

supply is restored to its proper level the encoder power supply

foldback circuit was activated. Remove all power to the drive

and connect the supply connections to the encoder. If upon

applying power, the supply again folds back, excessive current

draw is occurring. This could be due to shorted supply

connections or a damaged encoder. Check all wiring between

the 1395 terminal strip and the encoder. If the wiring is

functional, replace the encoder.

If the supply remains low even after the encoder is disconnected,

replace the Main Control Board.

The encoder output signals are lost due

to a malfunction of the line drivers in the

encoder device.

• Measure the encoder output signals at the 1395 terminal strip.

Place a scope probe at TB3-17 and at TB3-18 and reference

them to TE. These signals represent the differential channel

outputs for phase B. TB3-17 is inverted and TB3-18 is

non-inverted. Rotate the shaft of the motor, either by

mechanical means or under armature voltage feedback

control. The resulting waveform should be similar to Waveform

3. If the proper signal is not observed, replace the encoder.

• Note: If using armature voltage feedback to troubleshoot the

encoder, the set-up procedure for armature voltage feedback

must be performed first for proper operation.

• Use the same method to check phase A of the encoder output.

Place a scope probe at TB3-19 and TB3-20 and reference

them to TE. TB3-19 is inverted and TB3-20 is non-inverted.

Rotate the shaft of the motor, either by mechanical means or

under armature voltage feedback control. The resulting

waveform should be similar to Waveform 3. If the proper signal

is not observed, replace the encoder.

The encoder output signals are present

at TB3, but the quadrature relationship is

incorrect between phases A and B.

• Open the drive door and lower the Main Control Board

assembly. Locate test points TP12 and TP15 on the left side of

the board near U13. TP12 is the phase B signal and TP15 is

the phase A. Verify that proper quadrature exists between A

and B. Rotate the motor in the CCW direction, as viewed from

the commutator. The resulting waveform should be similar to

Waveform 1 shown in Figure 3-1. If the encoder signals are in

phase or 180 Deg out of phase, check the wiring to ensure that

the signal lines are not shorted. If the wiring is functional

replace the encoder.

Encoder output signals present at TB3,

not present on Main Control Board.

Encoder interface failure.

• Replace the Main Control board.

Aotewell Ltd industry-mall.net

Loading...

Loading...