Rockwell Automation Publication 1756-AT017A-EN-P - January 2013

Position-based Output Control with the MAOC Instruction 3

Product Diverting

In a product diverting application, product moves from one high-speed conveyor

to another via pneumatic or electrical drivers.

In this application, use the instruction to trigger the output when the product is

directly in front of the diverter.

This application is particularly useful for any kind of product quality rejection

system and also works well for material handling.

Operation

By itself, the MAOC instruction enables position-based output control in these

ways:

• Uses the position of any motion axis in a ControlLogix® system as the

position reference

• Uses any output or DINT

• Updates outputs based on the motion axis position at the motion group

coarse update rate, typically 1…32 ms

The instruction can update standard digital output modules at the coarse update

rate. However, some high speed applications require a higher degree of accuracy.

The 1756-OB16IS, 1756-OB16IEFS, and 1732E-OB8M8SR scheduled output

modules improve the accuracy of the MAOC instruction by supporting the

ability to schedule output On and Off times. All of the scheduling configuration

for an output’s On and Off times is completed through the MAOC instruction.

The instruction then updates values in the module’s output tags that define the

scheduled output behavior.

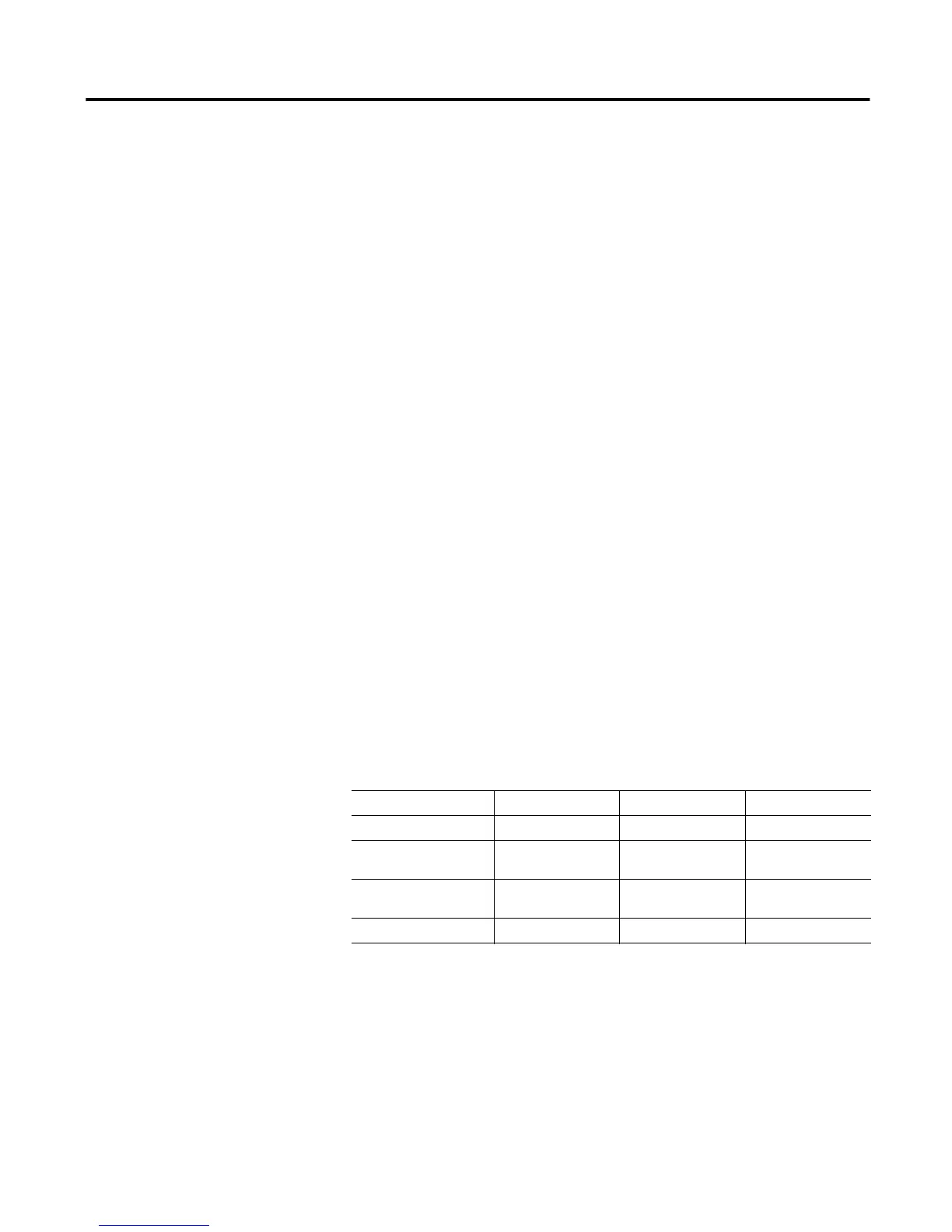

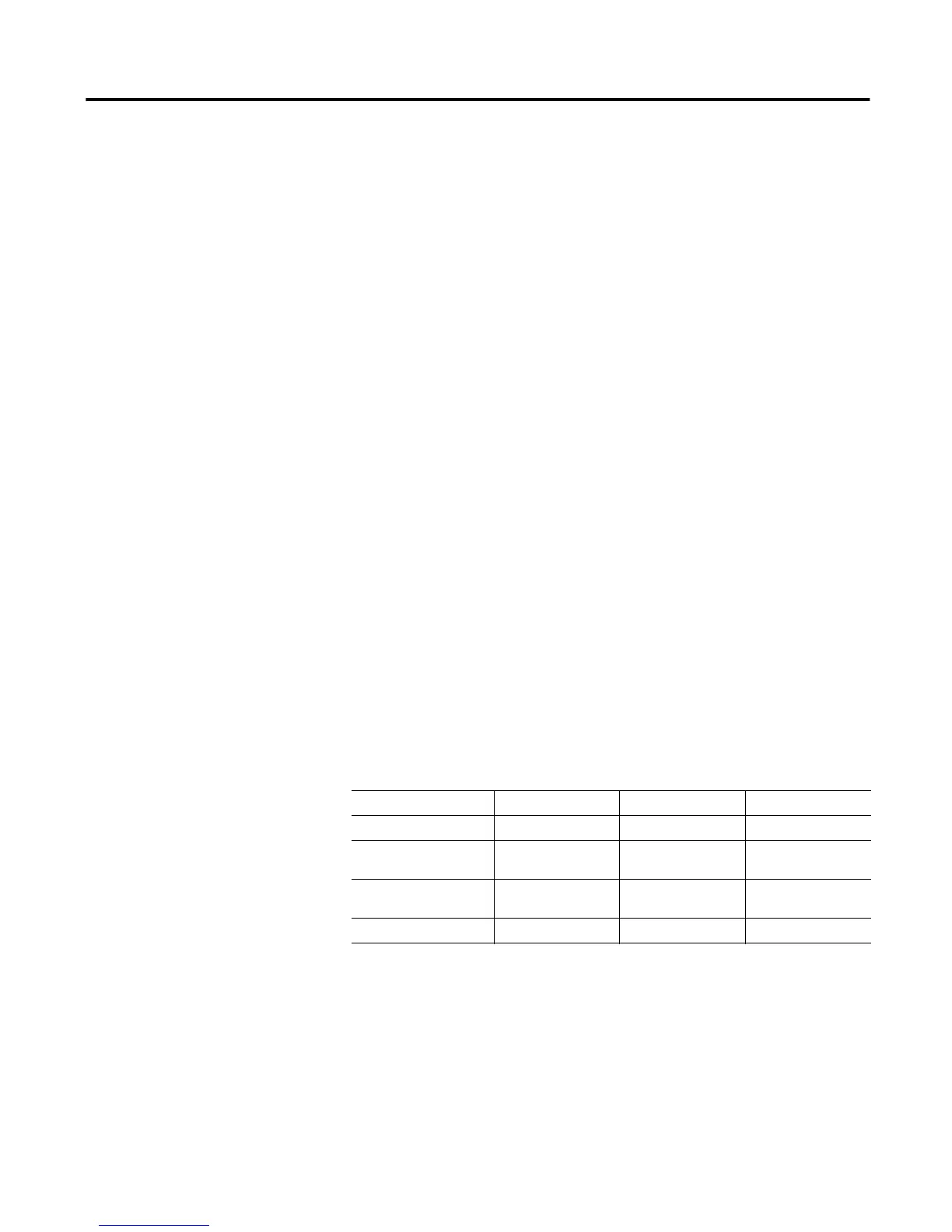

Table 1 - Scheduled Output Module Features

Feature 1756-OB16IS 1756-OB16IEFS 1732E-OB8M8SR

Number of schedules 16 32 16

Output points available

for scheduling

8 (points 0…7) 16 (points 0…15) 8 (points 0…7)

Remote operation None Remote chassis On-Machine™ over the

EtherNet/IP network

Minimum schedule interval

(1)

(1) The MAOC limits the minimum schedule interval (minimum pulse width) to 1/16 of the coarse update period.

100 μs 5 μs 100 μs

Loading...

Loading...