14 Rockwell Automation Publication 2080-UM004C-EN-E - March 2015

Chapter 2 Install and Wire Your Module

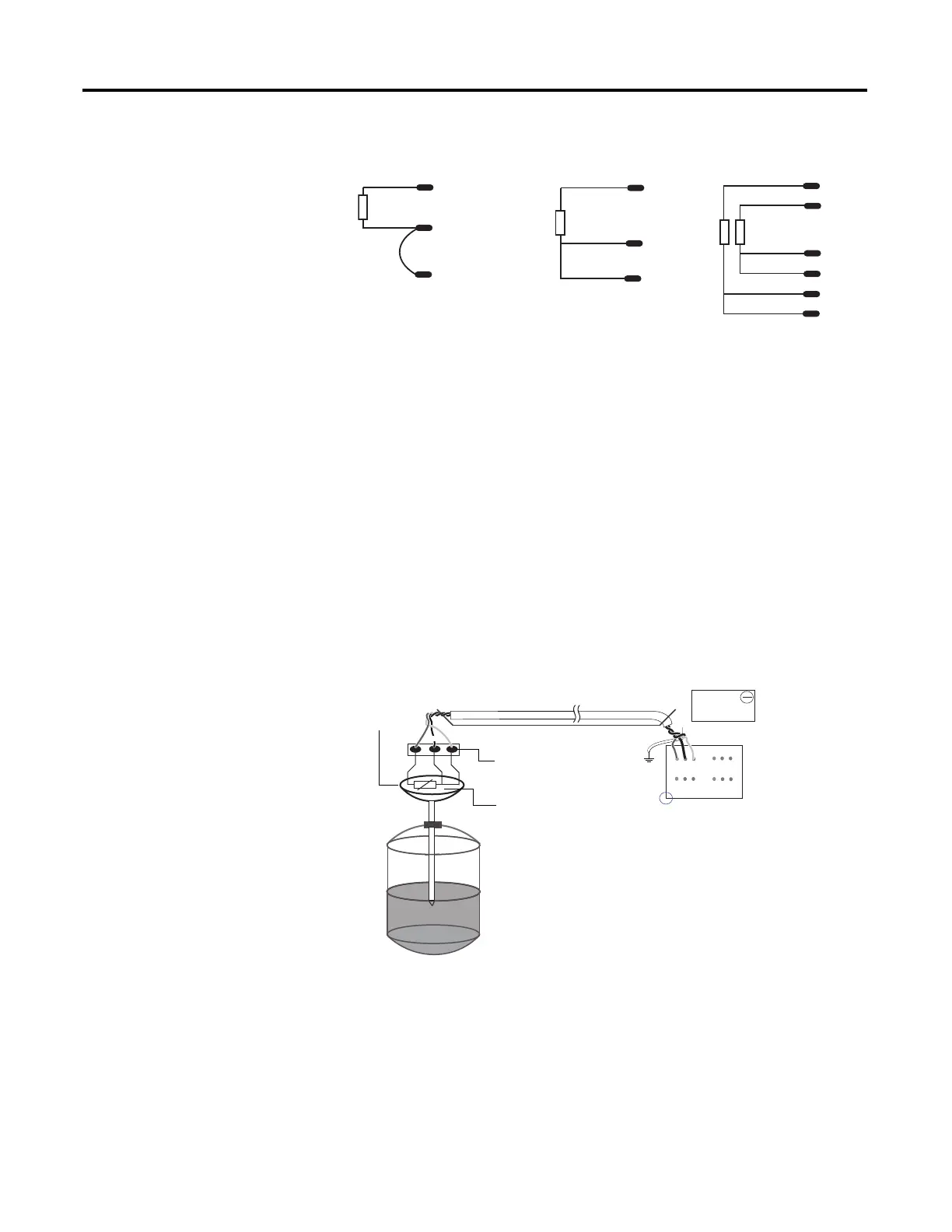

Wire the Sensors

For better accuracy in noisy industrial environments, 3- or 4-wire RTD sensors

are mostly used. While using these sensors, the resistance added by lead lengths is

compensated by an additional third wire in case of 3-wire RTD and two

additional wires, in bridge configuration, in case of 4-wire RTD. For 2-wire RTD

sensor in this module, this lead compensation is provided by using an external

50 mm 22 AWG shorting wire between terminals A2, A3 and B2, B3 for channel

0 and 1, respectively. Shielded twisted pair cables are to be utilized for remote use

of these sensors with cable shield grounded at controller end.

Wire the RTD Module and RTD Sensor in the Field

The RTD sensing element should always be connected between terminals B1(+)

and B2(-) for channel 1, and A1(+) and A2(-) for channel 0 in the module.

Terminals B3 and A3 should always be shorted to B2 and A2, respectively, to

complete the constant current loop. Mismatch in wiring can cause erroneous,

over, or underrange readings.

white

red

Ch0+

Ch0-

Ch0L

white

red

red

green

black

black

white

red

red

Ch1+

Ch1-

Ch1L

Ch0-

Ch0L

Ch0+

Ch0-

Ch0L

Ch0+

2-wire sensor

connection

3-wire single

sensor connection

3-wire dual

sensor connection

45778

NOTE: This illustration provides for channel 0 only for 2- and 3-

wire single sensor connections. The wire colors illustrate a

particular type of RTD sensor available in market.

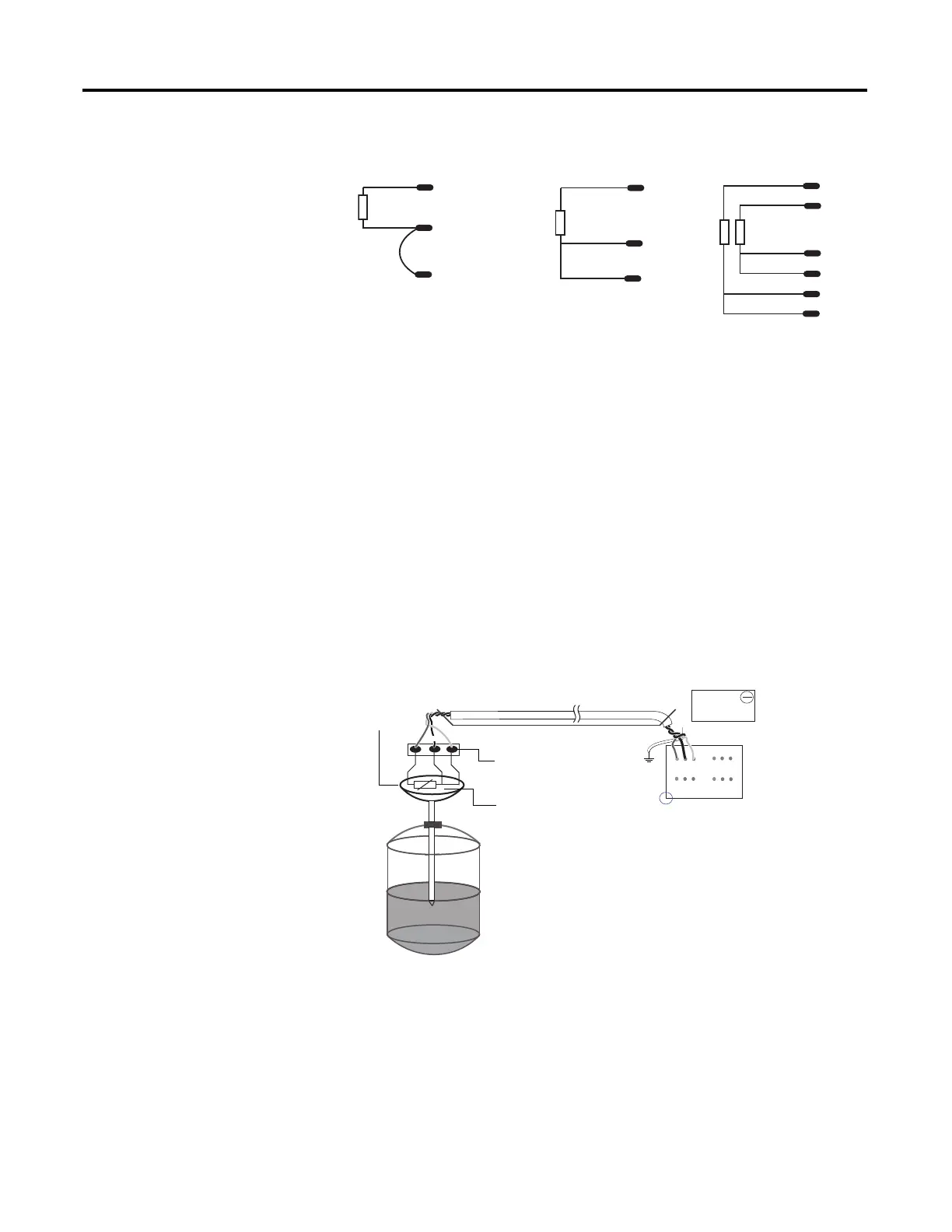

1

2

3

1 2 3 4 5 6

1 2 3 4 5 6

2080-RTD2

B

A

Red

Green

Black

Blue

Red

Blue

Black

Process

temperature

Measurement

Shielded twisted wire cable

Field screw

junction box

3-wire

RTD

Oil filled

thermowell

45779

3-wire RTD shown

Cable tray/conduit

Loading...

Loading...