12 Rockwell Automation Publication SAFETY-AT140A-EN-P - May 2015

Safety Function: Actuator Subsystems – Stop Category 1 via the PowerFlex 525 and PowerFlex 527 Drives with Safe Torque-off

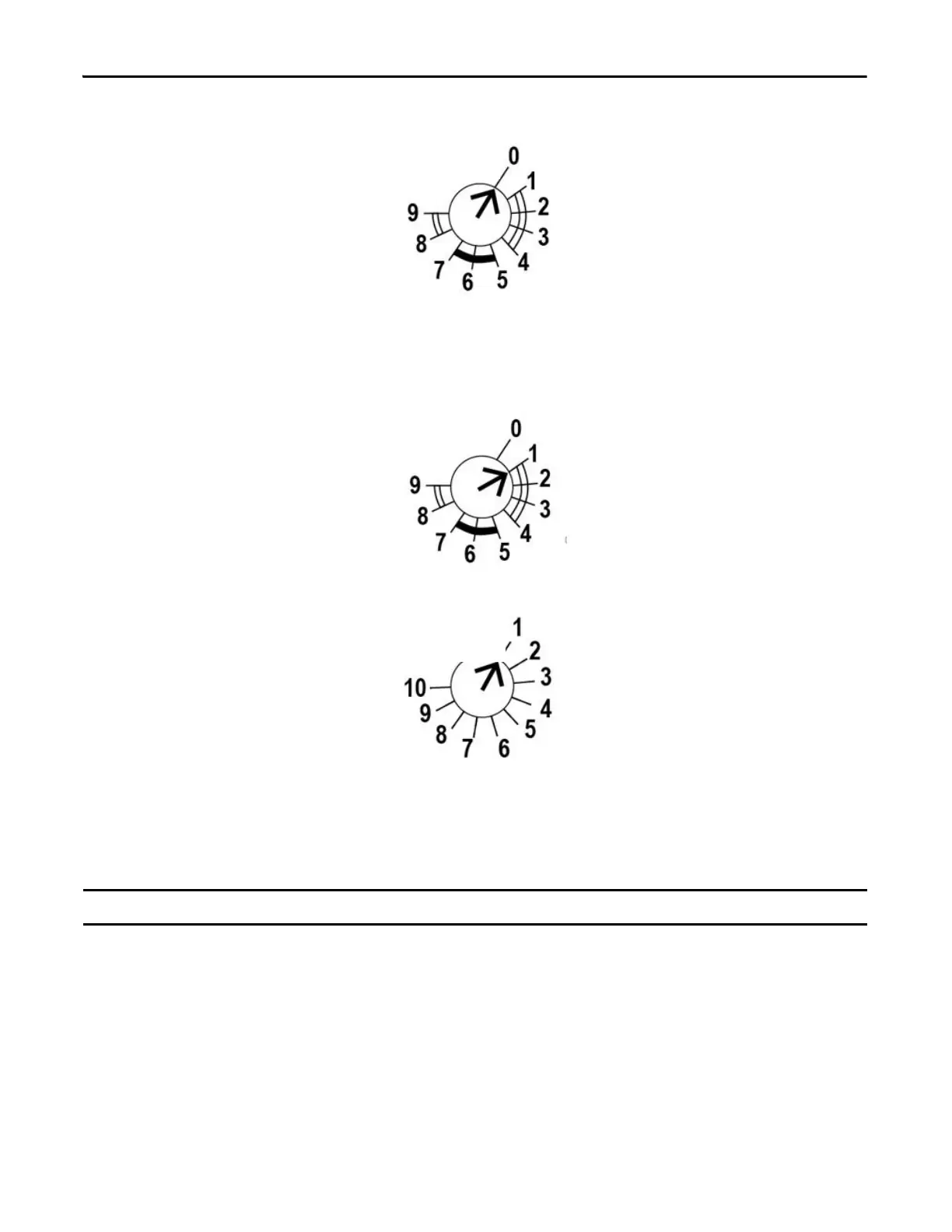

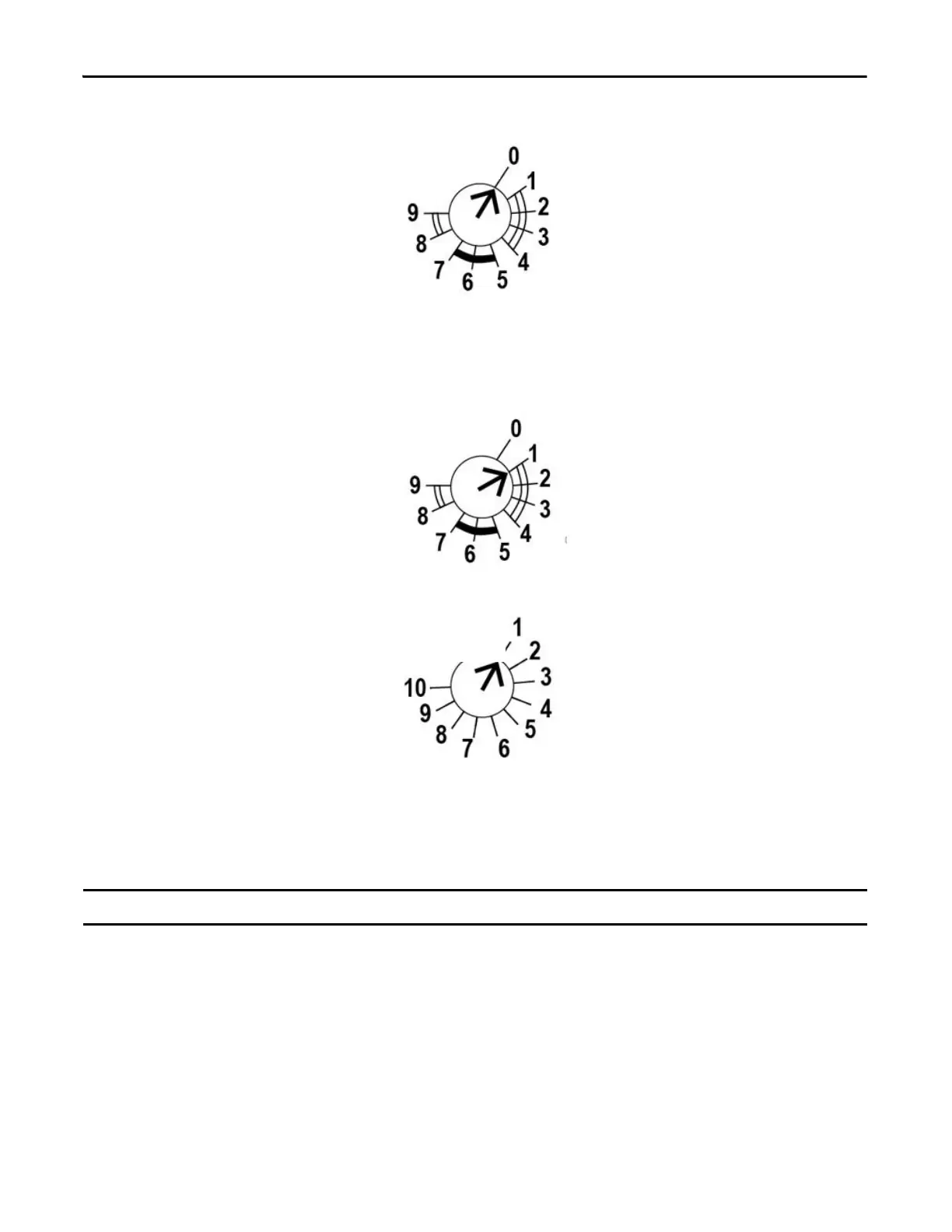

1. Start configuration/overwrite: With power off, turn the Range rotary switch to 0 and power up the unit.

After the power-up test, the PWR/Fault status indicator will flash red.

2. Set timing/mode configuration: Turn the Range rotary switch to 1 (0.1. to 1.0 second), and then turn the Time

rotary switch to 1 (10%).

The B1 and IN indicators blink the new setting. The PWR/Fault status indicator flashes steady green to indicate

that the positions are set.

3. Cycle power to the unit to store the configuration setting.

The configuration must be confirmed before operation. A white space is provided on the face of the unit to record the setting.

Loading...

Loading...