Rockwell Automation Publication SAFETY-AT140A-EN-P - May 2015 21

Safety Function: Actuator Subsystems – Stop Category 1 via the PowerFlex 525 and PowerFlex 527 Drives with Safe Torque-off

5 Close the gate. Press and release the Reset button. The Guardmaster dual-input safety

relay and the Guardmaster multifunction-delay expansion module reset. The

PowerFlex drive does not respond to the Start button. The PowerFlex drive’s STO fault

remains.

6 Remove the jumper. Press the drive Start button. The drive must not respond. The STO

fault remains.

7 Cycle power to the drive. The STO fault is cleared. Press the Start button. The hazardous

motion starts.

8 While the hazardous motion continues to run, jump 0V to terminal S1 of the

PowerFlex drive. The hazardous motion coasts to a stop. The Guardmaster dual-input

safety relay and the Guardmaster multifunction-delay expansion module are not

affected. The PowerFlex drive has an STO fault.

9 Remove the jumper. Press the drive Start button. The drive must not respond. The STO

fault remains.

10 Cycle power to the drive. The STO fault is cleared. Press the Start button. The hazardous

motion starts.

11 Repeat steps 1 through 10 using the PowerFlex drive’s terminal S2 in place of terminal

S1. The system responses must be the same as before.

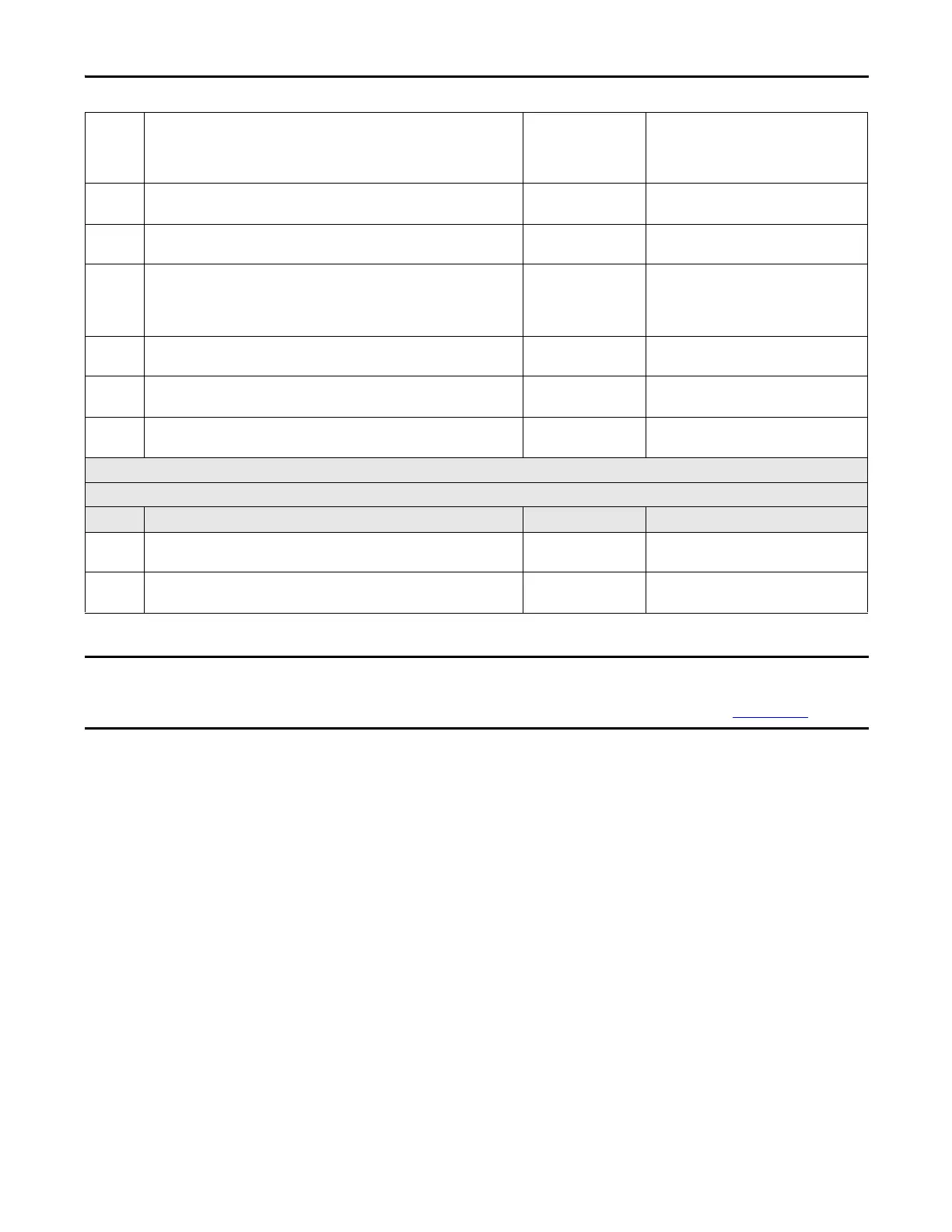

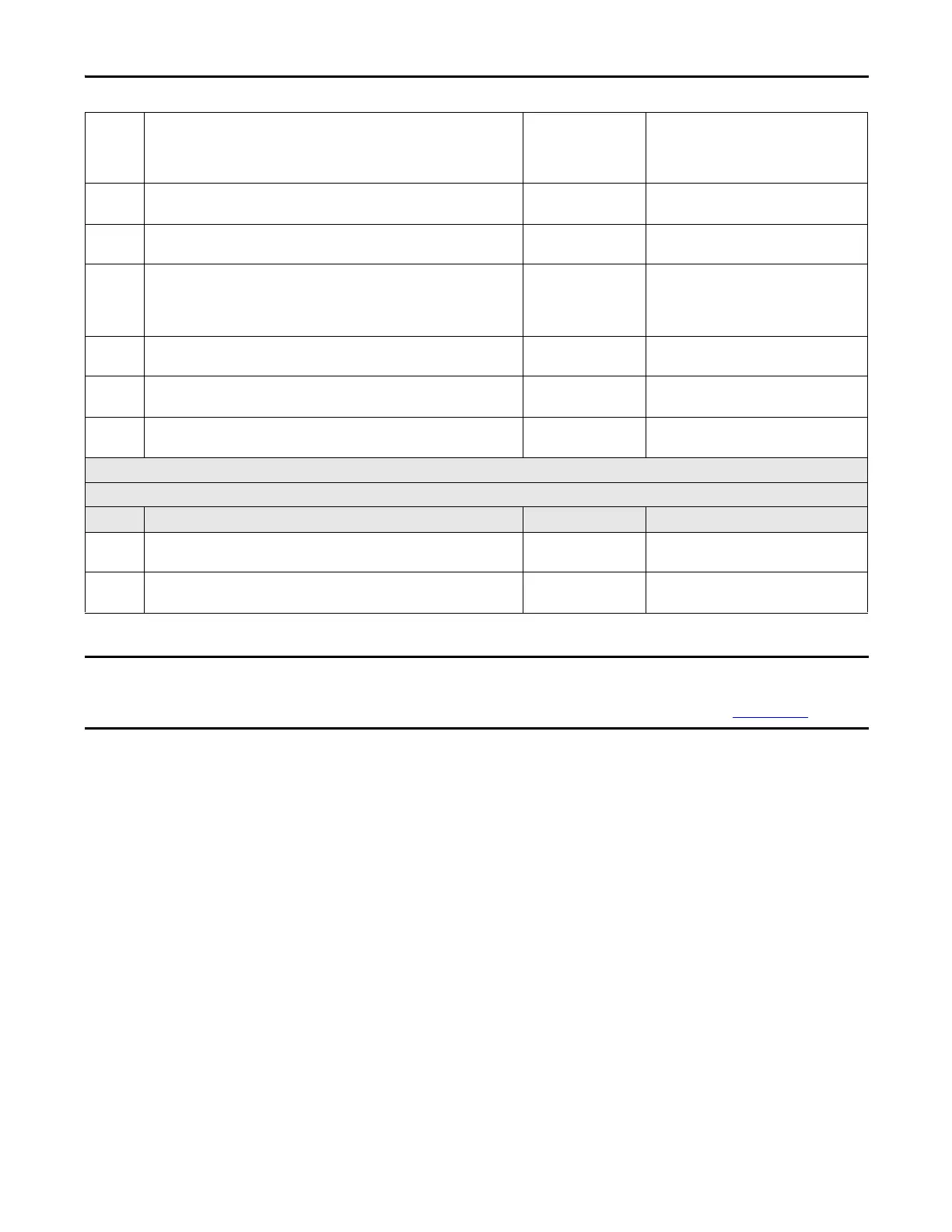

Confirmation of Performance - The overall system stopping performance does not exceed 476 ms.

SensaGuard Switch, Guardmaster Dual-input Safety Relay, Guardmaster Multifunction-delay Expansion Module, PowerFlex Drive Tests

Test Step Confirmation Pass/Fail Changes/Modifications

1 Confirm that everything runs safely in the configuration determined to yield the

maximum overall system stopping performance.

2 While the machine continues to run, open the guarded gate. Do not reach into the

guarded area. Confirm that the hazard stops within 476 ms.

In addition to the verification and validation steps provided here, consult the application technique for your input subsystem for

the steps required to validate the input device. For the input subsystem example used in this safety function application

technique, we reference Safety Function: Door Monitoring Products: SensaGuard™ / GSR DI, publication SAFETY-AT069

.

Loading...

Loading...