PowerFlex 750-Series Products with TotalFORCE Control 13

Rockwell Automation Publication 750-PC100A-EN-P - December 2016

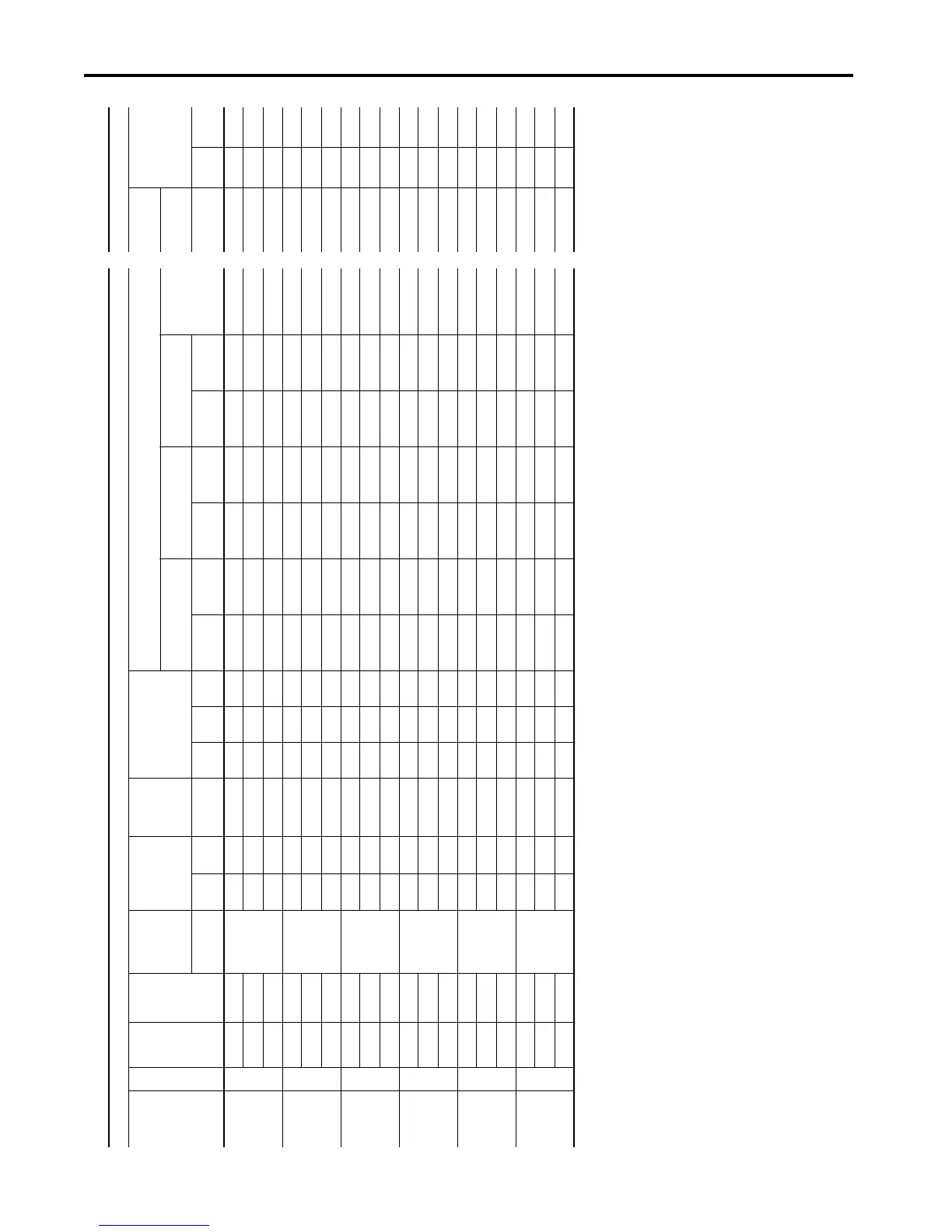

900 kW 9 1074 Light 20x…F920 1181 – 986 – 1600 – 1350 1800 1350 3000 1350 2500 1350 1183 1100 4

920 Normal 1012 1380 845 – 1600 – 1200 1600 1200 2500 1200 2400 1200 1014 1100 4

820 Heavy 1230 1476 753 – 1600 – 1100 1400 1100 2400 1100 2000 1100 904 1100 4

1000 kW 10 1150 Light 20x…F1K0 1265 – 1056 – 1250 900 1500 2000 1500 3500 1500 3000 1500 1267 1100 6

1030 Normal 1133 1545 946 – 1250 900 1350 1800 1350 3000 1350 2500 1350 1135 1100 6

920 Heavy 1380 1656 845 – 1250 900 1200 1600 1200 2500 1200 2400 1200 1014 1100 6

1100 kW 10 1344 Light 20x…F1K1 1478 – 1234 – 1250 900 1800 2400 1800 4000 1800 3500 1800 1481 1100 6

1150 Normal 1265 1725 1056 – 1250 900 1500 2000 1500 3500 1500 3000 1500 1267 1100 6

1030 Heavy 1545 1854 946 – 1250 900 1350 1800 1350 3500 1350 2500 1350 1135 1100 6

1400 kW 10 1582 Light 20x…F1K4 1740 – 1452 – 1250 900 2000 3000 2000 4500 2000 4000 2000 1743 1100 6

1419 Normal 1561 2129 1303 – 1250 900 1800 2400 1800 4000 1800 3500 1800 1564 1100 6

1162 Heavy 1743 2092 1067 – 1250 900 1500 2000 1500 3500 1500 3000 1500 1280 1100 6

1800 kW 11 2091 Light 20x…F1K8 2300 – 1919 1600 1600 – 3000 3500 3000 6000 3000 5000 3000 2304 1100 8

1865 Normal 2052 2798 1712 1600 1600 – 2400 3500 2400 5000 2400 4500 2400 2055 1100 8

1535 Heavy 2303 2763 1409 1600 1600 – 2000 2500 2000 4500 2000 3800 2000 1692 1100 8

2300 kW 12 2599 Light 20x…F2K3 2859 – 2386 1600 1600 900 3500 4500 3500 6000 3500 6000 3500 2864 1100 10

2318 Normal 2550 3477 2128 1600 1600 900 3000 4000 3000 6000 3000 6000 3000 2554 1100 10

2020 Heavy 3030 3636 1855 1600 1600 900 3000 3500 3000 6000 3000 5000 3000 2226 1100 10

(1) ‘Applied Rating’ refers to the motor that will be connected to the drive. For example, a ‘F330’ drive can be used in Normal Duty mode on a 315 kW motor, in Heavy Duty mode on a 250 kW motor or in Light Duty mode on a 355 kW motor. The drive can be programmed for each mode. Wiring and fuses can be

sized based on the programmed mode. For any given drive catalog number, Normal Duty mode provides higher continuous current but smaller overload current with respect to Heavy Duty mode. See parameter 306 [Duty Rating].

Refer to Specifications for an explanation of Duty Ratings.

(2) These AC line fuses (with blown fuse indicators) are included in the drive to provide drive short circuit protection. AC input protection devices for branch circuit protection based on US NEC are listed in the table. Each LCL filter has one fuse per phase.

(3) Minimum protection device size is the lowest rated device that supplies maximum protection without nuisance tripping.

(4) Maximum protection device size is the highest rated device that supplies drive protection. For US NEC, minimum size is 125% of motor FLA. Ratings shown are maximum.

(5) Circuit Breaker - inverse time breaker. For US NEC, minimum size is 125% of motor FLA. Ratings shown are maximum.

(6) Recommended Motor circuit protector - Instantaneous trip circuit breaker. The trip setting should be set to the input current of the drive and should be sized for the continuous current of the system.

(7) These DC line fuses (with blown fuse indicators) are included in the drive to provide drive short circuit protection.

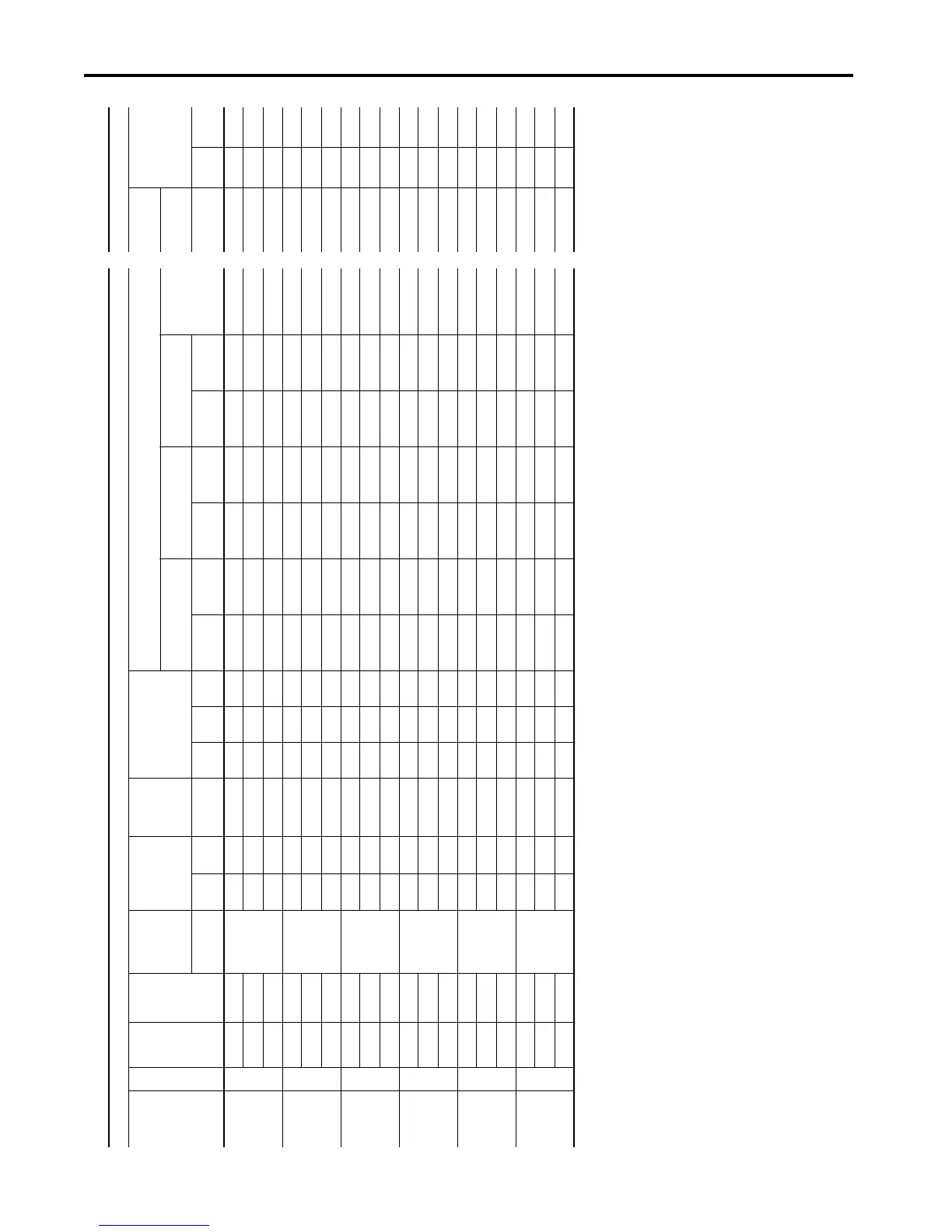

690 Volt AC and 932 Volt DC Input Protection Devices - Frames 8…12 (continued)

690 Volt AC Input 932 Volt DC Input

Applied

Rating

(1)

Frame

Cont.

Output

Amps

Duty

Catalog

Number

Output

Overload Amps

Continuous

AC Input

AC Input Integral

Semiconductor Fuse

Size

(170M Type)

(2)

AC Input Protection Devices

Input

Quantities

DC Input

Integral

Semiconductor

Fuse Kit

(7)

Dual Element Time

Delay Fuse

Non-Time Delay Fuse Circuit Breaker

(5)

Motor Circuit

Protector

(6)

Continuous

DC Input

(x = G or J) 1 min 3 sec Amps 2xLCL

Amps

2xLCL

Amps

1xLCL

Amps

1/Phase

Min

(3)

Max

(4)

1/Phase

Min

(3)

Max

(4)

Min Max Amps Amps Qty.

Loading...

Loading...