Rockwell Automation Publication 750-PC100A-EN-P - December 2016

PowerFlex 750-Series Products with TotalFORCE Control 17

Grounding Requirements

The Safety Ground-PE must be connected to system ground. Ground impedance must conform to the

requirements of national and local industrial safety regulations and/or electrical codes. The integrity of all

ground connections should be periodically checked.

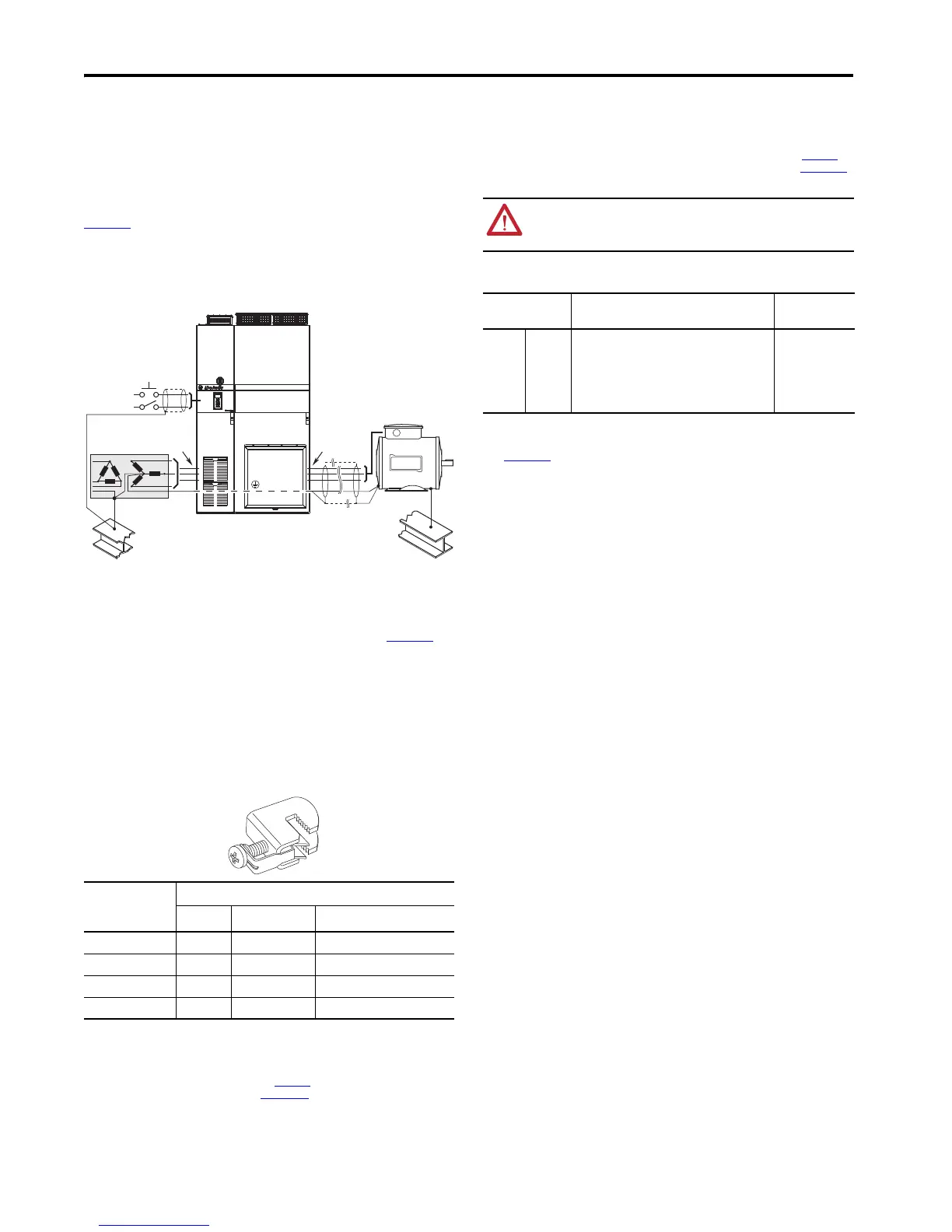

Recommended Grounding Scheme

A single point (PE only) grounding scheme should be used. Some applications may require alternate grounding

schemes, refer to Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives, publication

DRIVES-IN001

, for more information. These applications include installations with long distances between

drives or drive line-ups, which could cause large potential differences between the drive or line-up grounds.

For installations within a cabinet, a single safety ground point or ground bus bar connected directly to building

steel should be used. All circuits including the AC input ground conductor should be grounded independently

and directly to this point/bar.

Typical Grounding

Shield Termination - SHLD

The Shield terminal provides a grounding point for the motor cable shield. It must be connected to an earth

ground by a separate continuous lead. Connect the motor cable shield to this terminal on the drive (drive end)

and the motor frame (motor end). Use a shield terminating conduit fitting to connect shield to this terminal. See

Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives, publication DRIVES-IN001

.

RFI Filter Grounding

Using an optional RFI filter may result in relatively high ground leakage currents. Therefore, the filter must

only be used in installations with grounded AC supply systems and be permanently installed and

solidly grounded (bonded) to the building power distribution ground. Be sure that the incoming supply

neutral is solidly connected (bonded) to the same building power distribution ground. Grounding must not rely

on flexible cables and should not include any form of plug or socket that would permit inadvertent

disconnection. Some local codes may require redundant ground connections. The integrity of all connections

should be periodically checked. Refer to the instructions supplied with the filter.

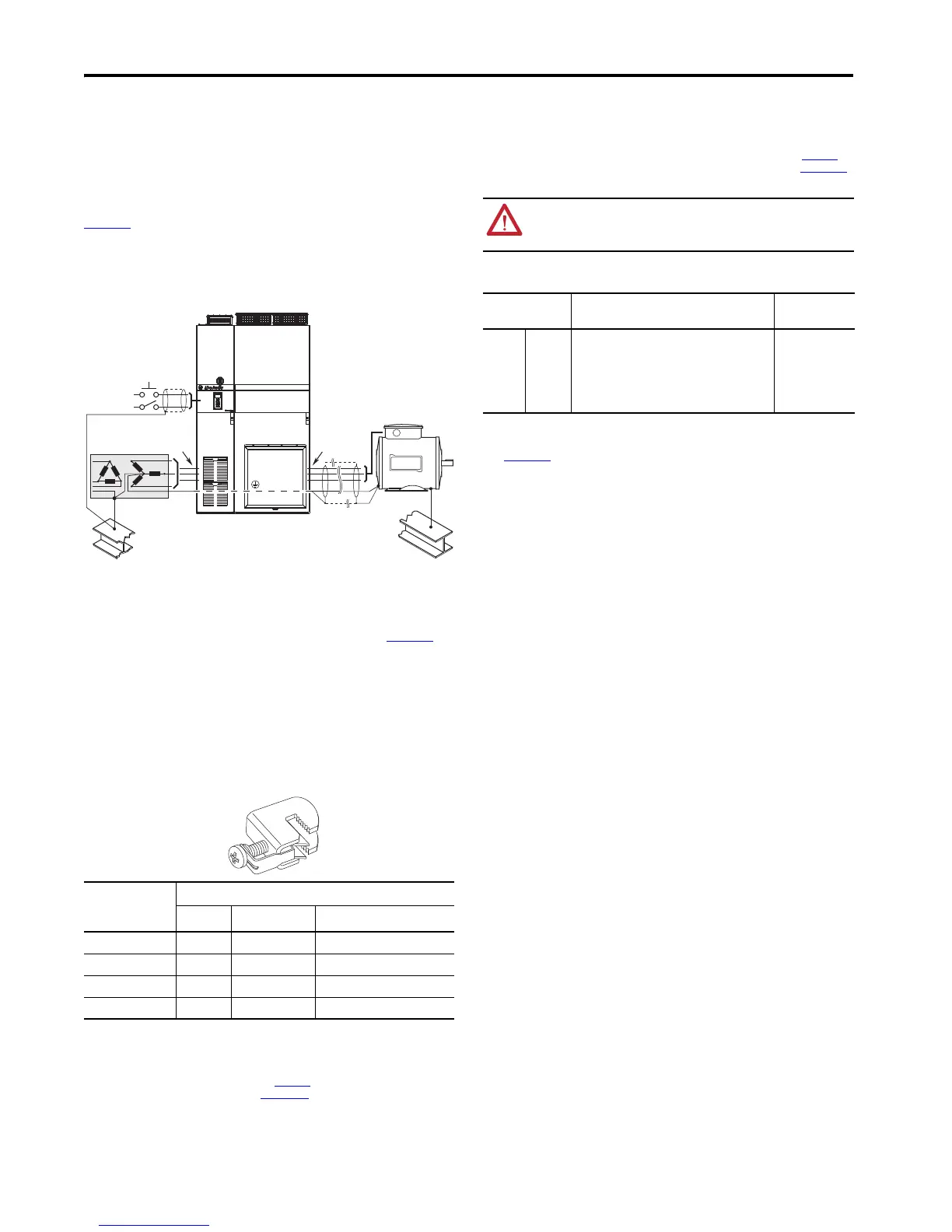

Grounding Clamps

The clamp kits listed in this table can be

used to secure round copper ground

conductors to 9.5 mm (0.37 in.) thick

ground bus bars.

The final assembly Safety Ground-PE must be connected to system ground. Ground impedance must conform to

the requirements of national and local industrial safety regulations and/or electrical codes. Periodically check

the integrity of all ground connections. For more information on grounding requirements, see PowerFlex 755TM

IP00/Open Type Kits Installation Instructions, publication 750-IN101

, and Wiring and Grounding Guidelines for

Pulse Width Modulated (PWM) AC Drives, publication DRIVES-IN001

.

Power Wiring

The following section describes the cabling recommendations for three-phase power and motor connections.

For detailed installation instructions including cable entry and exit and customer connections options, refer to

the PowerFlex 750-Series Products with TotalFORCE Control Installation Instructions, publication 750-IN100

. see

also Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives, publication DRIVES-IN001

,

for more information on grounding.

Kit Catalog Number Conductor Cross-sections

ISO (mm

2

)

AWG/MCM Tightening Torque N•m (lb•in)

SK-RM-GRNDCLMP-16 2.5…16 14…6 AWG 3 (27)

SK-RM-GRNDCLMP-50 16…50 6…0 AWG 8 (71)

SK-RM-GRNDCLMP-75 35…75 2…00 AWG 12 (106)

SK-RM-GRNDCLMP-185 70…185 00 AWG …350 MCM 15 (133)

U (T1)

V (T2)

W (T3)

R (L1)

S (L2)

T (L3)

SHLD

PE

ATTENTION: National codes and standards (NEC, BSI, and so forth) and local codes outline

provisions for safely installing electrical equipment. Installation must comply with specifications

regarding wire types, conductor sizes, branch circuit protection, and disconnect devices. Failure to

do so can result in personal injury and/or equipment damage.

Cable Recommendations

Type Cable Description Minimum

Insulation Rating

Power

(1)

(2)

(3)

(1) Control and signal wires should be separated from power cables by at least 0.3 meters (1 foot).

(2) The use of shielded cable for AC input power may not be necessary but is always recommended.

(3) See Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives, publication

DRIVES-IN001

.

Standard • Three tinned copper conductors with XLPE insulation.

• Maximum 500 MCM conductors.

• Copper braid/aluminum foil combination shield and

tinned copper drain wire, three drain wires per cable

assembly.

•PVC jacket.

600V,

75 °C (167 °F)

Loading...

Loading...