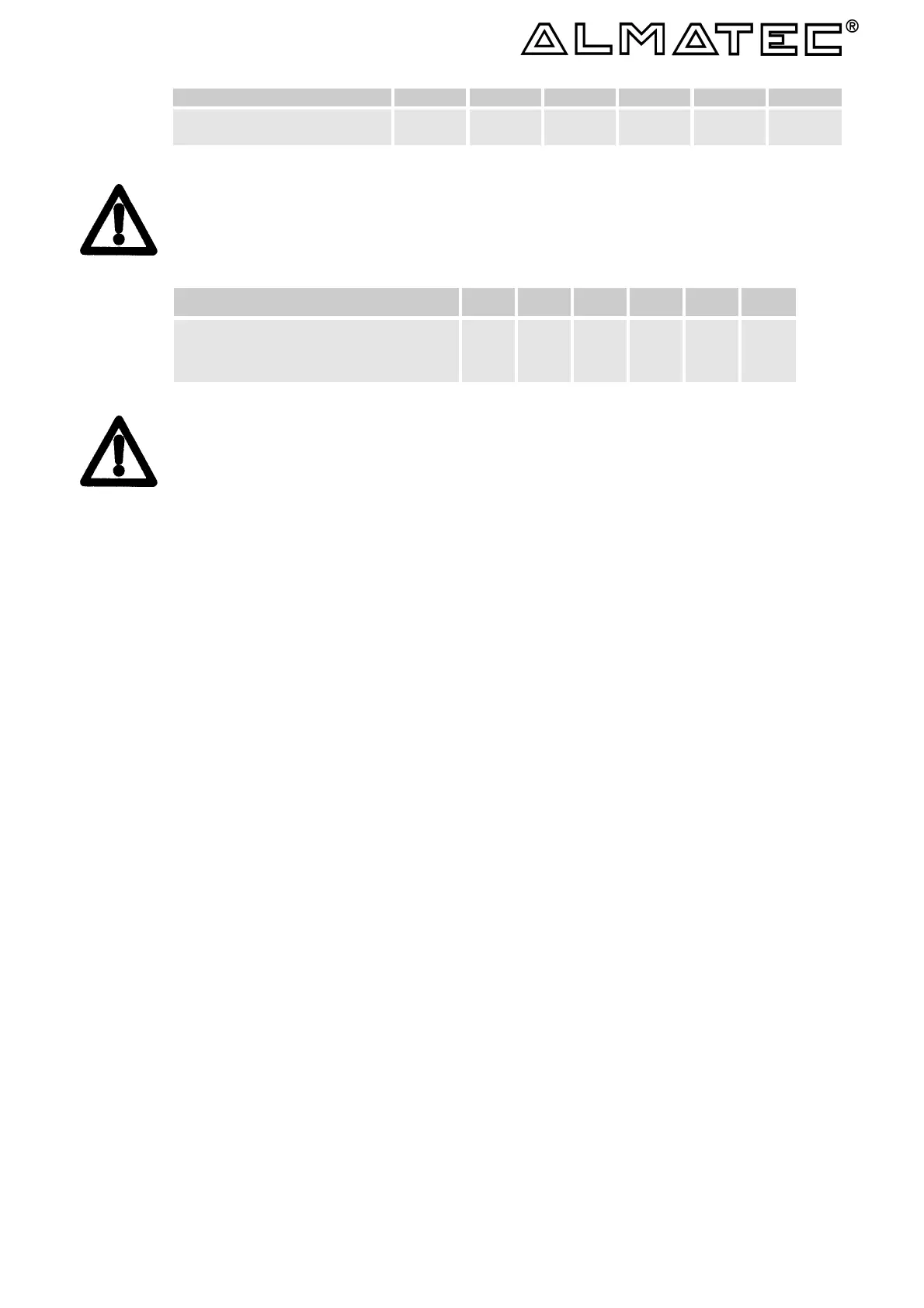

Size A 08 A 10 A 15 A 25 A 40 A 50

Max. number of strokes/min.

at nominal performance

500 430 240 160 140 100

Before putting the pump into operation as well as after some hours of pumping, the housing bolts

[15] have to be fixed according to the torque data of the following schedule, as the elements of

construction "settle". The valve stops discharge valve [6] and the plugs [7,8] have to be fixed too.

Fixing all these parts is necessary as well after longer periods of stoppage, at extreme

temperature variations, after transport and dismantling the pump.

Size A 08 A 10 A 15 A 25 A 40 A 50

Torque values for housing bolts (Nm):

PE-pumps

PTFE-pumps

-

2

-

4,5

8

6

13

10

17

14

22

18

• Installation, operation, and maintenance by qualified staff only.

• Pressure tests of the plant a pump is included in may only be carried out with the pump

disconnected from the pressure on both ports or by using the pressure the pump develops

while operating. The load of a pressure in the plant may damage the pump.

• Pump must not be operated with a positive suction pressure.

• Depending on the conditions of operation, the liquid conveyed might escape from the pump

through the muffler in case of a diaphragm rupture (in this case muffler has to be replaced).

For further safety requirements the optional equipment diaphragm monitoring and barrier

chamber system are recommended.

• The state of the muffler has to be inspected regularly, as a blocked muffler can be forced out

of the pump. If this happens, damages of properties and/or persons cannot be excluded.

• If the product tends to settle, the pump has to be flushed regularly. For larger solids a filter

has to be installed in the suction line.

• In case of delivery of hot liquids the wetted pump must not standstill for a longer time,

because it could lead to temporary leaks in the valve area and to a blockade of the air control

system.

• The relevant effective security advises have to be respected.

• Pumps of the A-Series must not be submerged.

• Pools of liquid which appear in the near outer area of the pump have to be inspected on

danger potential, if necessary safety measures are to be taken.

• Chemical and biological reactions in the product chamber of the pump (mixture of different

substances) and the freezing of the liquid have to be avoided.

• Especially when deliver critical liquids, wear parts, like diaphragms, should be replaced within

a preventive maintenance.

• The use of non-original ALMATEC spare parts and structural changes lead to the lapse of the

warranty immediately. When operating such a pump, damages of properties and/or persons

cannot be excluded.

• The operation of the pump with nitrogen as driving gas is possible. In closed rooms a

sufficient ventilation must be provided.

Providing spare parts

We recommend to have the spare part kits S on stock. These include the relevant spare parts for your pump.

5

Loading...

Loading...