10

C048-699-30 R03, Rev. B (01/2021)

Step 3. Once the DCX unit is in it's nal position, mark the DCX

mounting bracket hole locations onto the battery stack frame top

rails (see Figure 10).

Step 4. Uninstall the termination plate from the battery terminals, then

uninstall the DCX mounting brackets from the DCX unit.

Step 5. Align the DCX mounting brackets with the marked locations from

Step 3 and secure into place by tightening the included self-

tapping screws (EnerSys/C&D/GNB battery kits, Figure 11) or by

tightening the included 1/4 in. hardware into the threaded inserts

of the mounting brackets (East Penn Manufacturing kits).

Step 6. Reinstall the DCX unit into position again as described in Step 2,

then tighten all hardware. See Table 4 for DCX mounting

bracket to DCX chassis torque specications.

NOTE: REFER TO BATTERY MANUFACTURER TORQUE

SPECIFICATIONS FOR TIGHTENING BATTERY

TERMINATION PLATE TO BATTERY TERMINAL POSTS

(FIGURE 12).

NOTICE:

Table 4. Mounting Bracket to DCX Chassis Torque Specications

TERMINATION

TYPE

HOLE/STUD

SIZE

RECOMMENDED

TORQUE VALUE

Threaded Insert 3/8 in. 50 in·lbs

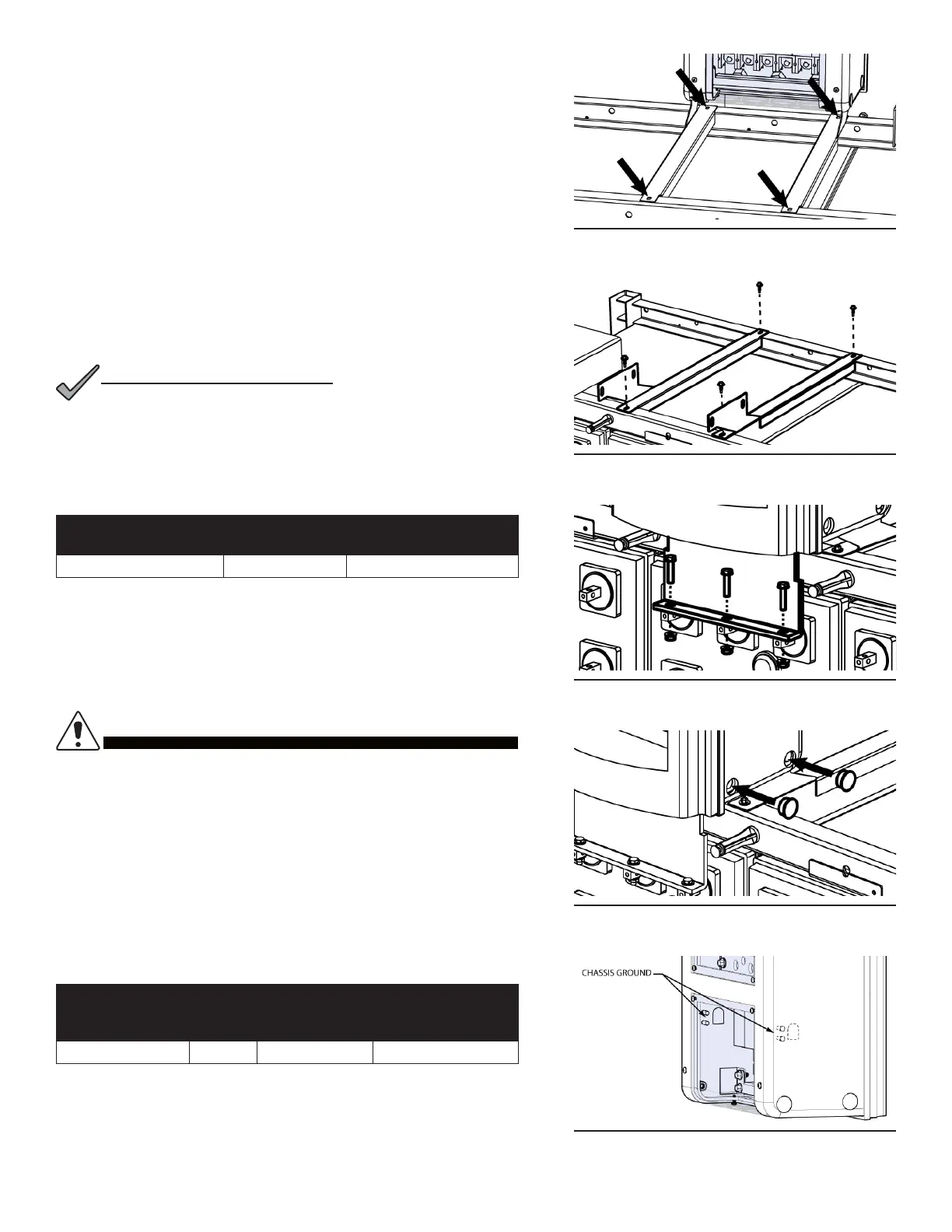

Step 7. After mechanical mounting of DCX unit has been completed,

snap the two black plastic hole plugs into the access holes that

cover the 3/8 in. mounting bolts (see Figure 13)

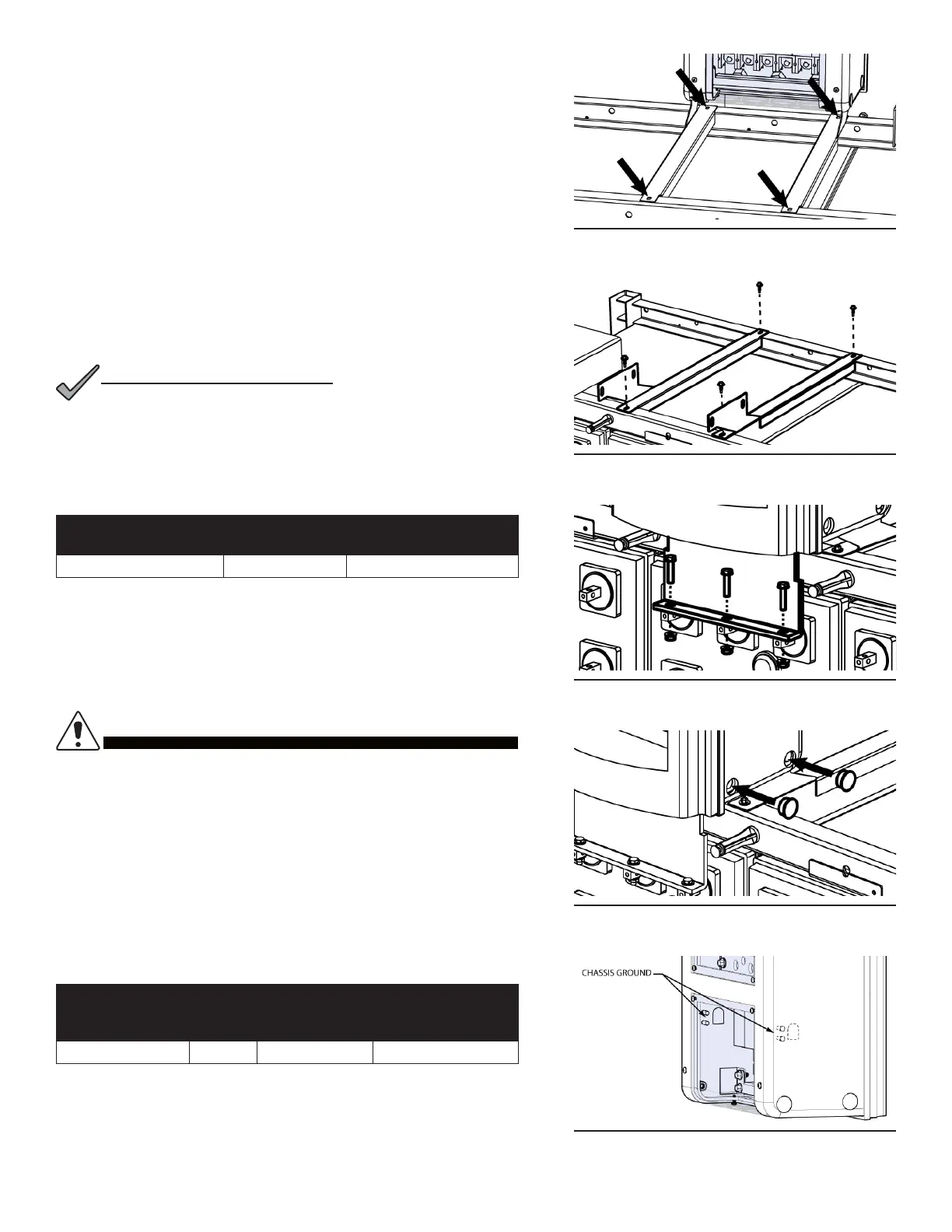

4.4 4.4 Chassis GroundChassis Ground

DO NOT ENERGIZE THE DCX BATTERY

DISCONNECT SWITCH BEFORE CHASSIS GROUND

IS CONNECTED.

CAUTION!

Two chassis ground landings are located on the inside of the DCX

chassis (see Figure 14). Refer to mechanical drawing found in

Appendix A.3 for greater detail regarding grounding locations. A

minimum of #6 AWG chassis ground cable is required. IMPORTANT:

Grounding hardware not included. A properly-sized grounding

conductor must be installed per NEC (250.122).

Table 5. Chassis Ground Specications

TERMINATION

TYPE

HOLE/

STUD

SIZE

CENTER TO

CENTER

RECOMMENDED

TORQUE VALUE

Threaded Stud 1/4 in. 5/8 in. 5.83 ft·lbs

Step 1. Select the desired grounding location and break away the

associated knock-out points found on the clear plastic covers.

Step 2. Connect the ground cable with 1/4 in. hardware. Ensure heat

shrink and no-oxide compound are applied appropriately prior to

termination. Torque the fasteners to 5.83 ft·lbs (see Table 5).

Figure 10. Mark bracket locations

Figure 11. Secure brackets

Figure 12. Secure to cell terminals

Figure 13. Insert hole plugs

Figure 14. Chassis ground

Loading...

Loading...