26

Alpha InTec² 25X Eand 28XE - Commissioning

5.4 CHECK THE AIR FLOW THROUGH THE HEAT EXCHANGER

The following air flow check must be carried out and the reading logged in the box provided in the table below. This figure is

then used as a reference during future servicing of the boiler to determine if the heat exchanger needs to be cleaned.

This check must be carried out with the front case fitted.

Before carrying out this check the flue must be fully installed and the condensate trap filled with water.

1. Remove the pressure test point caps at the top of the boiler and connect a digital differential pressure gauge across the

positive (F+) and negative (A-) pressure connections, see Fig. 5.3.

2. Set the boiler to stand by and press and hold the reset and stand by buttons simultaneously for 15 seconds. The

summer/winter symbol (

) and the number 55 will flash on the display indicating that the fan is running at a fixed

speed of 5500 rpm.

Note: The boiler does not fire during this operation.

3. Observe the pressure differential reading and compare it to the tables below and record the figure in the box at the

bottom of the table to be used as a reference for future servicing.

If on a future service the pressure reading has reduced by 40% or more then the heat exchanger must be cleaned.Refer to

Section 6.5.

i.e. If the measured value is less than 0.6 x the original reference value, the heat exchanger should be inspected and cleaned.

4. If during first commissioning the readings are not within those stated in the tables above then the flue must be checked

for integrity and length. If the flue length exceeds 5 m then the 'F0' parameter should be changed to suit, see parameter

settings in Section 5.14.

Note: If the 'F0' parameter has been changed then a fast calibration is required see Section 5.13. This is indicated by

the code E72 shown on the display.

The air flow check function will operate for 15 minutes, alternatively disconnect the boiler electrical supply or press the

standby button

for 8 seconds to exit the function early.

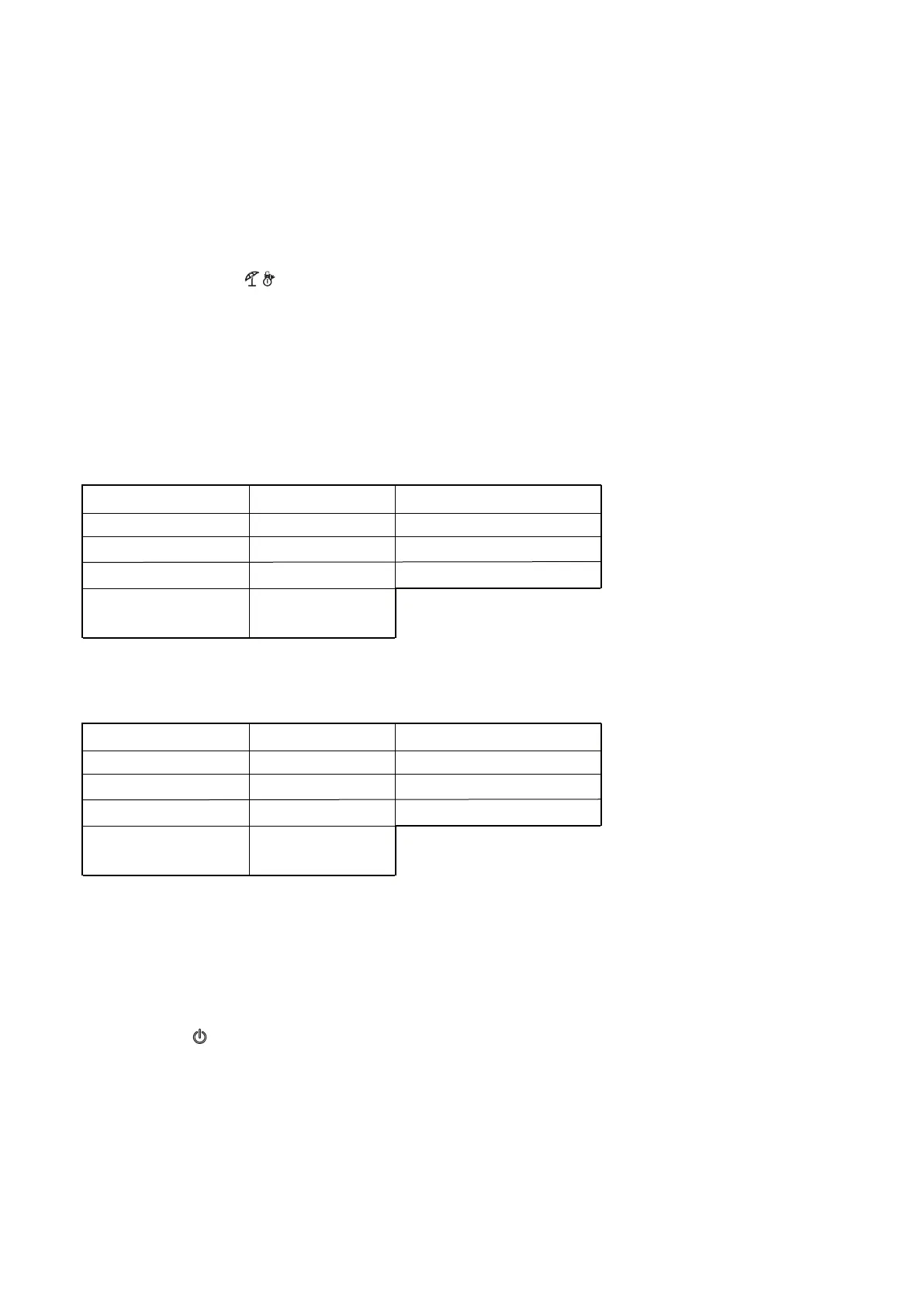

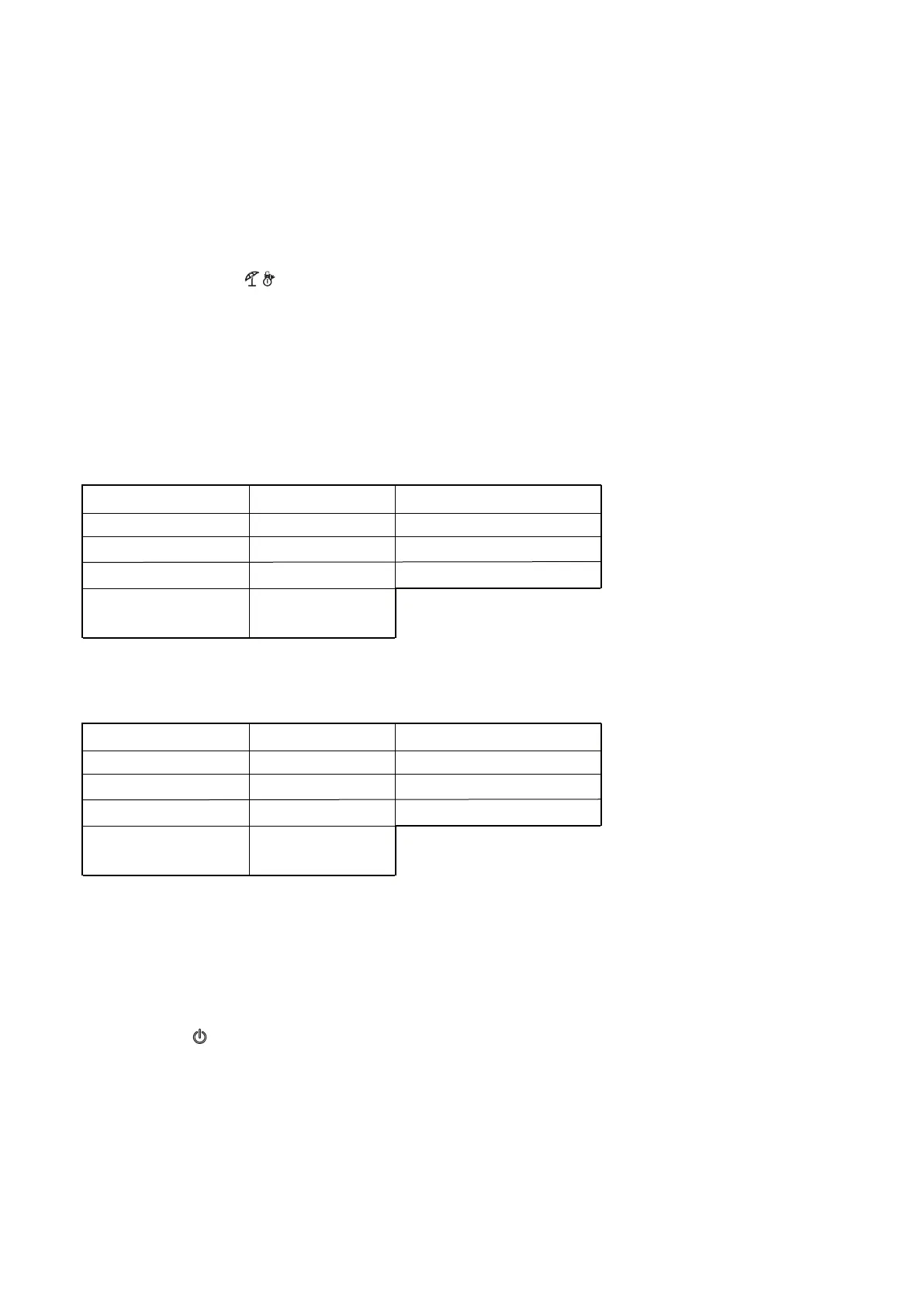

InTec² 25XE

InTec² 28XE

'F0' parameter setting

0

1

2

Recorded pressure

reading

Pressure (mbar)

0 to 1.68

1.68 to 2.02

2.02 to 2.40

Indicative flue length (m)

From 0 to 4.5

From 4.5 to 9.0

From 9.0 to 13.0

'F0' parameter setting

0

1

2

Recorded pressure

reading

Pressure (mbar)

0 to 1.58

1.58 to 1.81

1.81 to 2.02

Indicative flue length (m)

From 0 to 4.5

From 4.5 to 9.0

From 9.0 to 13.0

Loading...

Loading...