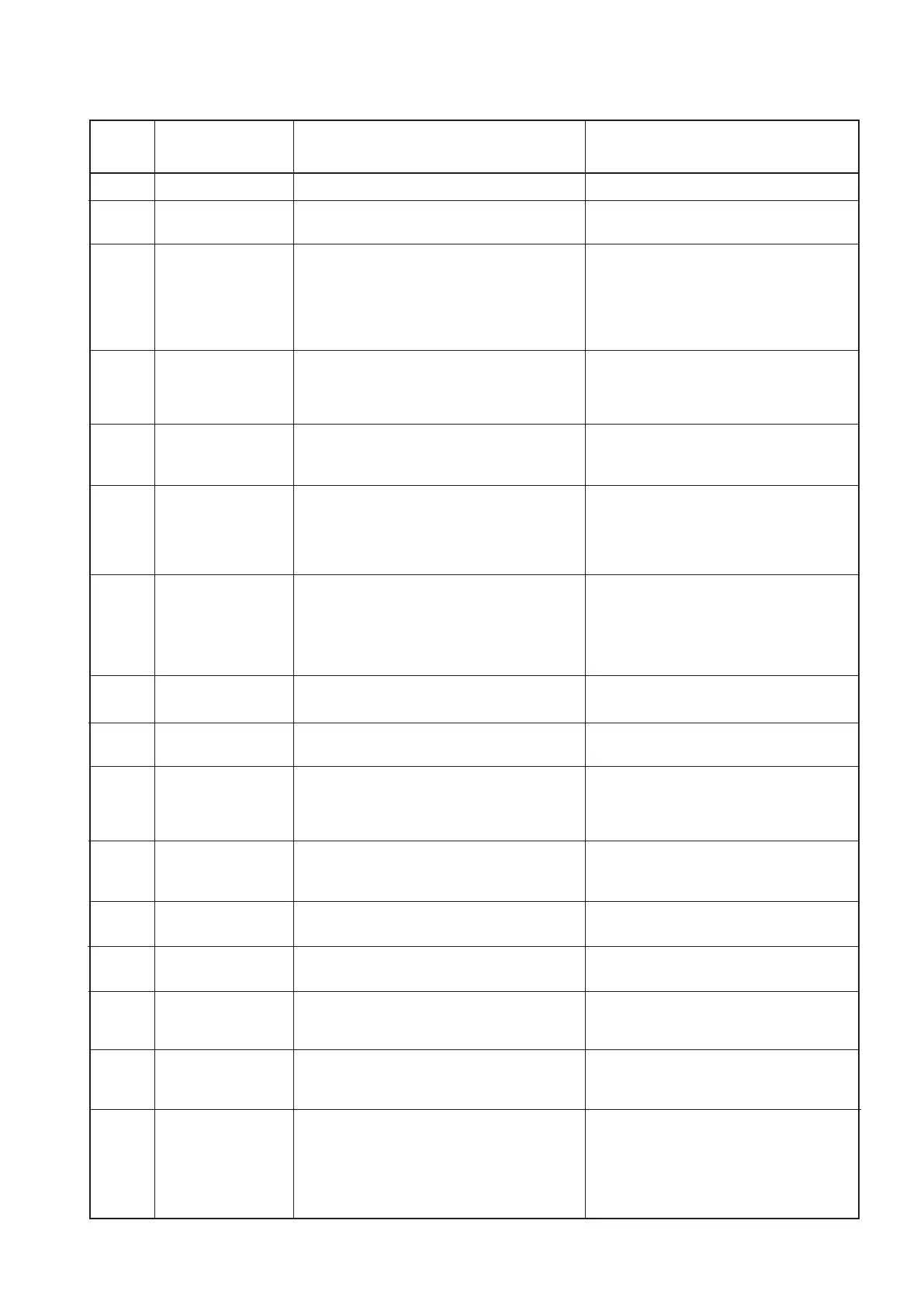

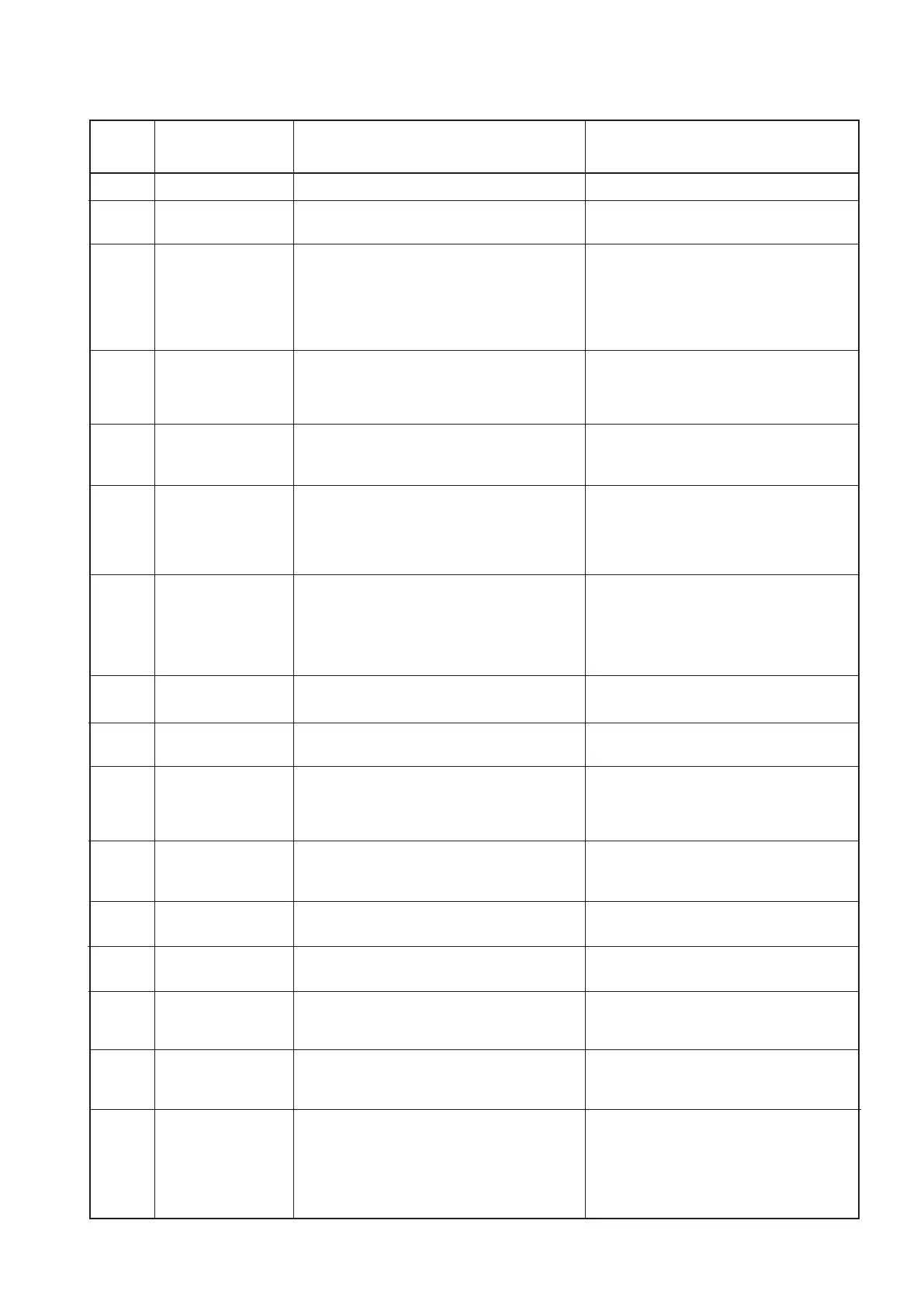

47

Alpha InTec² 25XE and 28XE - Error Codes and Fault Finding

Error

code

Fault Fault description Possible causes

Not used on this model

Insufficient supply voltage to operate boiler

Flame detected but signal lost. Ignition retries

after fan purge

Repeated loss of flame signal during operation

This fault can occur if the flue is exposed to high

wind conditions (shown as E38 in the fault code

history in the INFO menu)

The boiler has attempted to fire repeatedly for the

maximum time limit

No continuity on external sensor circuit

Check link is present in external connections

14 and 15 or if fitted external safety device has

activated

Flue thermostat has sensed high flue gas

temperature (110°C) and reduced the burner

output to prevent damage. If the temperature

continues to rise the boiler will lock out and E03

will be displayed

Error between communication of the Climatic

transmitter and boiler receiver

The PCB detects an incorrect mains supply

voltage frequency

The pump is stuck or there is an electrical pump

fault

Restricted CH flow due to air or a circuit restriction

This may occur when the PCB is replaced or if

the parameters are altered in the air/gas section

The PCB detects that some parameters have

been altered

The board detects an anomaly in the temperature

readings difference between the flow NTC and

safety NTC sensors

The PCB detects an anomaly on the safety NTC

sensor

An anomaly on the gas valve control is detected

BUS connection fault

Low supply voltage

Loss of flame

rectification

Loss of flame

rectification

Safety lock out

Low supply voltage

Optional external

safety sensor

intervention

Reduced burner

output

Climatic RF

communication fault

Mains supply voltage

frequency block

Pump fault

Air in the pump

Full boiler calibration

required

Fast calibration

required

High flow NTC and

safety NTC difference

detected

Safety flow sensor

anomaly

Anomaly on the gas

valve control

36

37

38

43

44

46

47

51

59

60

61

62

72

73

74

77

78

79

Check mains power supply

Check for bad cable connections etc

Check flame sensing electrode and lead

Check for flue gas recirculation

Check the gas valve

Check flue system and termination

Check gas supply/working pressure

Check/adjust combustion settings

Check as above for error code 38

Check external control (room thermostat)

requests

Rapid on/off tap requests

Check external sensor and cable are not

damaged or wet

Check continuity of external sensor and circuit

Check connections 14 and 15 on connection

panel

Air in heat exchanger

Restricted primary flow

Heat exchanger air flow blocked

Flue restriction

Flue sensor fault

Pump fault

Batteries require replacing

Check mains power supply

Faulty PCB

Check the pump operation, it may be necessary

to free the pump shaft (refer to Section 2.4)

Check the pump wiring

Replace the pump

Check Flow and Return valves are open

Check for correct system pressure

Check the system is purged properly

Carry out full calibration process as described in

Section 5.13

Carry out fast calibration process as described

in Section 5.13

Faulty flow or safety NTC sensor

Check resistance reading on the sensors

Poor system circulation or blockage

Faulty safety NTC sensor

Check resistance reading on sensor

Replace the safety NTC sensor

Check the electrode condition, replace if

necessary

Check the inlet gas pressure is correct and

carry out a full calibration process as described

in Section 5.13

If the fault persists replace gas valve

Loading...

Loading...