3

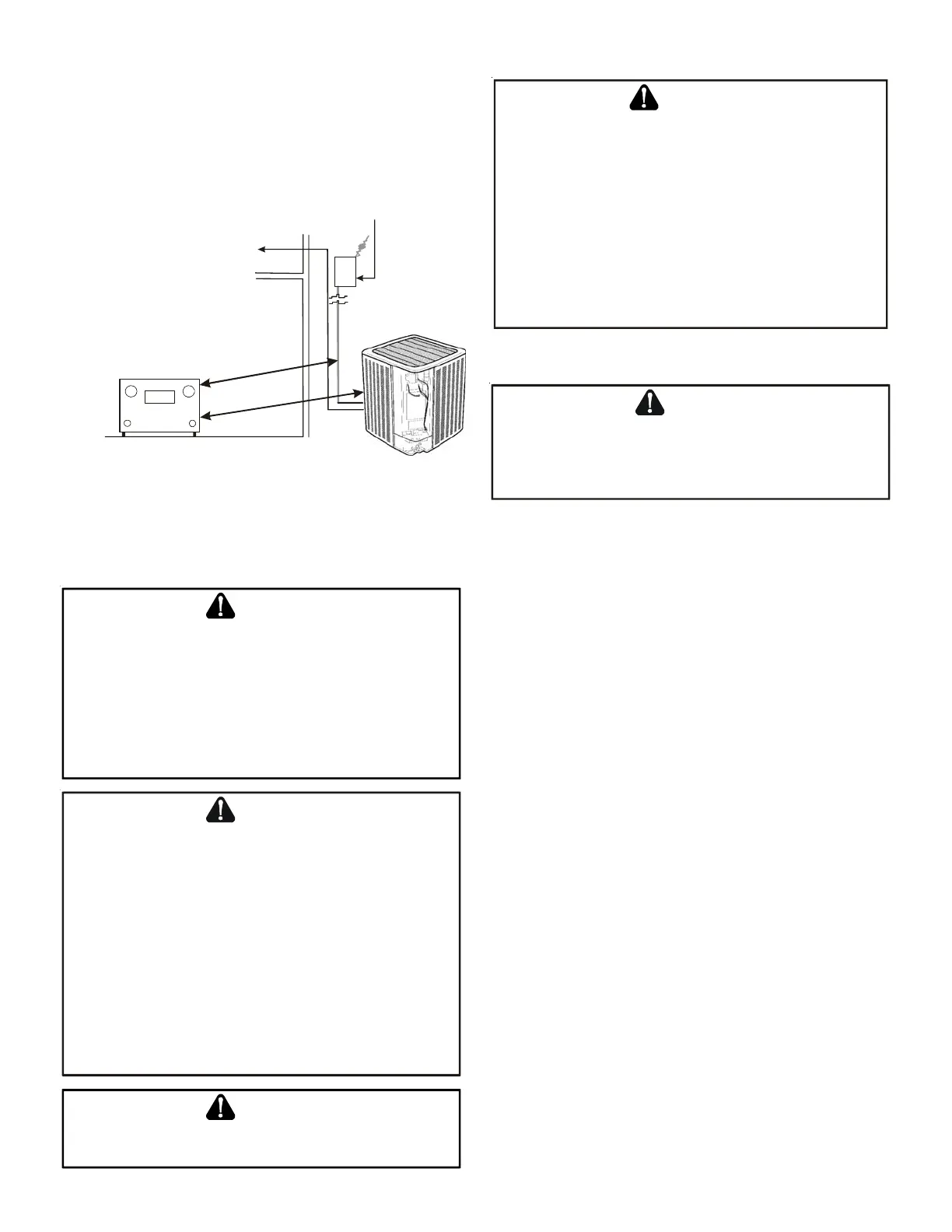

ELECTRICAL NOISE

The unit should be well grounded so that potential effects of elec-

trical noise from the inverter to surrounding equipment can be

minimized.

When selecting an installation location, keep sufficient distance

from the heat pump unit and wiring to radios, personal comput-

ers, stereos, etc., as shown in the following figure.

Circuit

Breaker

(In.)

Radio, TV

6

0

”

o

r

m

o

r

e

To Indoor Unit and Thermostat

6

0

”

o

r

m

o

r

e

Placement to Minimize Electronic Noise

S

AFE

R

EFRIGERANT

H

ANDLING

While these items will not cover every conceivable situation, they

should serve as a useful guide.

T

O

AVOID

POSSIBLE

EXPLOSION

,

USE

ONLY

RETURNABLE

(

NOT

DISPOSABLE

)

SERVICE

CYLINDERS

WHEN

REMOVING

REFRIGERANT

FROM

A

SYSTEM

.

• E

NSURE

THE

CYLINDER

IS

FREE

OF

DAMAGE

WHICH

COULD

LEAD

TO

A

LEAK

OR

EXPLOSION

.

• E

NSURE

THE

HYDROSTATIC

TEST

DATE

DOES

NOT

EXCEED

5

YEARS

.

• E

NSURE

THE

PRESSURE

RATING

MEETS

OR

EXCEEDS

400

PSIG

.

W

HEN

IN

DOUBT

,

DO

NOT

USE

CYLINDER

.

WARNING

R

EFRIGERANTS

ARE

HEAVIER

THAN

AIR

. T

HEY

CAN

“

PUSH

OUT

”

THE

OXYGEN

IN

YOUR

LUNGS

OR

IN

ANY

ENCLOSED

SPACE

. T

O

AVOID

POSSIBLE

DIFFICULTY

IN

BREATHING

OR

DEATH

:

• N

EVER

PURGE

REFRIGERANT

INTO

AN

ENCLOSED

ROOM

OR

SPACE

. B

Y

LAW

,

ALL

REFRIGERANTS

MUST

BE

RECLAIMED

.

• I

F

AN

INDOOR

LEAK

IS

SUSPECTED

,

THOROUGHLY

VENTILATE

THE

AREA

BEFORE

BEGINNING

WORK

.

• L

IQUID

REFRIGERANT

CAN

BE

VERY

COLD

. T

O

AVOID

POSSIBLE

FROSTBITE

OR

BLINDNESS

,

AVOID

CONTACT

AND

WEAR

GLOVES

AND

GOGGLES

. I

F

LIQUID

REFRIGERANT

DOES

CONTACT

YOUR

SKIN

OR

EYES

,

SEEK

MEDICAL

HELP

IMMEDIATELY

.

• A

LWAYS

FOLLOW

EPA

REGULATIONS

. N

EVER

BURN

REFRIGERANT

,

AS

P

OISONOUS

GAS

WILL

BE

PRODUCED

.

WARNING

T

O

AVOID

POSSIBLE

INJURY

,

EXPLOSION

OR

DEATH

,

PRACTICE

SAFE

HANDLING

OF

REFRIGERANTS

.

WARNING

T

O

AVOID

POSSIBLE

EXPLOSION

:

•N

EVER

APPLY

FLAME

OR

STEAM

TO

A

REFRIGERANT

CYLINDER

. I

F

YOU

MUST

HEAT

A

CYLINDER

FOR

FASTER

CHARGING

,

PARTIALLY

IMMERSE

IT

IN

WARM

WATER

.

•N

EVER

FILL

A

CYLINDER

MORE

THAN

80%

FULL

OF

LIQUID

REFRIGERANT

.

•N

EVER

ADD

ANYTHING

OTHER

THAN

R-410A

TO

A

RETURNABLE

R-410A

CYLINDER

. T

HE

SERVICE

EQUIPMENT

USED

MUST

BE

LISTED

OR

CERTIFIED

FOR

THE

TYPE

OF

REFRIGERANT

USE

.

•S

TORE

CYLINDERS

IN

A

COOL

,

DRY

PLACE

. N

EVER

USE

A

CYLINDER

AS

A

PLATFORM

OR

A

ROLLER

.

WARNING

R

EFRIGERANT

L

INES

T

HE

COMPRESSOR

PVE

OIL

FOR

R-410A

UNITS

IS

EXTREMELY

SUSCEPTIBLE

TO

MOISTURE

ABSORPTION

AND

COULD

CAUSE

COMPRESSOR

FAILURE

. D

O

NOT

LEAVE

SYSTEM

OPEN

TO

ATMOSPHERE

ANY

LONGER

THAN

NECESSARY

FOR

INSTALLATION

.

CAUTION

Use only refrigerant grade (dehydrated and sealed) copper tubing

to connect the heat pump unit with the indoor unit. After cutting

the tubing, install plugs to keep refrigerant tubing clean and dry

prior to and during installation. Tubing should always be cut

square keeping ends round and free from burrs. Clean the tubing

to prevent contamination. The liquid line must be insulated if

more than 50 ft. of liquid line will pass through an area that may

reach temperatures of 30 °F or higher than ambient in cooling

mode and/or if the temperature inside the conditioned space may

reach a temperature lower than ambient in heating mode. Never

attach a liquid line to any uninsulated potion of the gas line.

Do NOT let refrigerant lines come in direct contact with plumbing,

ductwork, floor joists, wall studs, floors, and walls. When run-

ning refrigerant lines through a foundation or wall, openings

should allow for sound and vibration absorbing material to be

placed or installed between tubing and foundation. Any gap be-

tween foundation or wall and refrigerant lines should be filled

with a pliable silicon-based caulk, RTV or a vibration damping

material. Avoid suspending refrigerant tubing from joists and studs

with rigid wire or straps that would come in contact with the

tubing. Use an insulated or suspension type hanger. Keep both

lines separate and always insulate the gas line.

Insulation is necessary to prevent condensation from forming

and dropping from the gas line. Armflex or satisfactory equiva-

lent with 3/8” min. wall thickness is recommended. In severe

conditions (hot, high humidity areas) 1/2” insulation may be re-

quired. Insulation must be installed in a manner which protects

tubing and connections from damage and contamination.

Loading...

Loading...