25

To connect an electronic air cleaner using the line voltage

EAC terminal:

• Turn OFF power to the furnace before installing any

accessories.

• Follow the air cleaner manufacturers’ instructions

for locating, mounting, grounding, and controlling

accessories. Utilize 1/4” quick connect terminals to

make accessory wiring connections to the furnace

integrated control module.

• Connect the hot terminal utilized for accessory

operation to the EAC terminal and the neutral side

of power to NEUTRAL bus on the integrated furnace

control or the neutral connection in the furnace

junction box.

• All eld wiring must conform to applicable codes.

• If it is necessary for the installer to supply additional

line voltage wiring to the inside of the furnace, the

wiring must conform to all local codes, and have a

minimum temperature rating of 105°C.

• All line voltage wire splices must be made inside the

furnace junction box.

StartuP ProCedure & adjuStment

Furnace must have a 115 VAC power supply properly connected

and grounded. Proper polarity must be maintained for correct

operation. In addition to the following start-up and adjustment

items, refer to further information in Operational Checks section.

drAin trAp priming

The drain trap MUST be primed prior to furnace startup. To

prime, ll both sides of the drain trap with water. This ensures

proper furnace drainage upon startup and prohibits the possi-

bility of ue gases escaping through the drain system.

furnACe operAtion

Purge gas lines of air prior to startup. Be sure not purge lines into

an enclosed burner compartment. Follow NFPA 54, National

Fuel Gas Code for proper purging methods. In Canada, follow

approved purging methods in CAN/CSA B149.1-15.

Check for leaks using an approved chloride-free soap and

water solution, an electronic combustible gas detector, or other

approved method. Verify that all required kits (propane gas,

high altitude, etc.) have been appropriately installed.

furnACe StArtup

1. Close the manual gas shutoff valve external to the furnace.

2. Turn off the electrical power to the furnace.

3. Set the room thermostat to the lowest possible setting.

4. Remove the burner compartment door.

NOTE: This furnace is equipped with an ignition device which

automatically lights the burner. Do not try to light the burner

by hand.

OFF

100% CFM 100% CFM

1 min

OFF

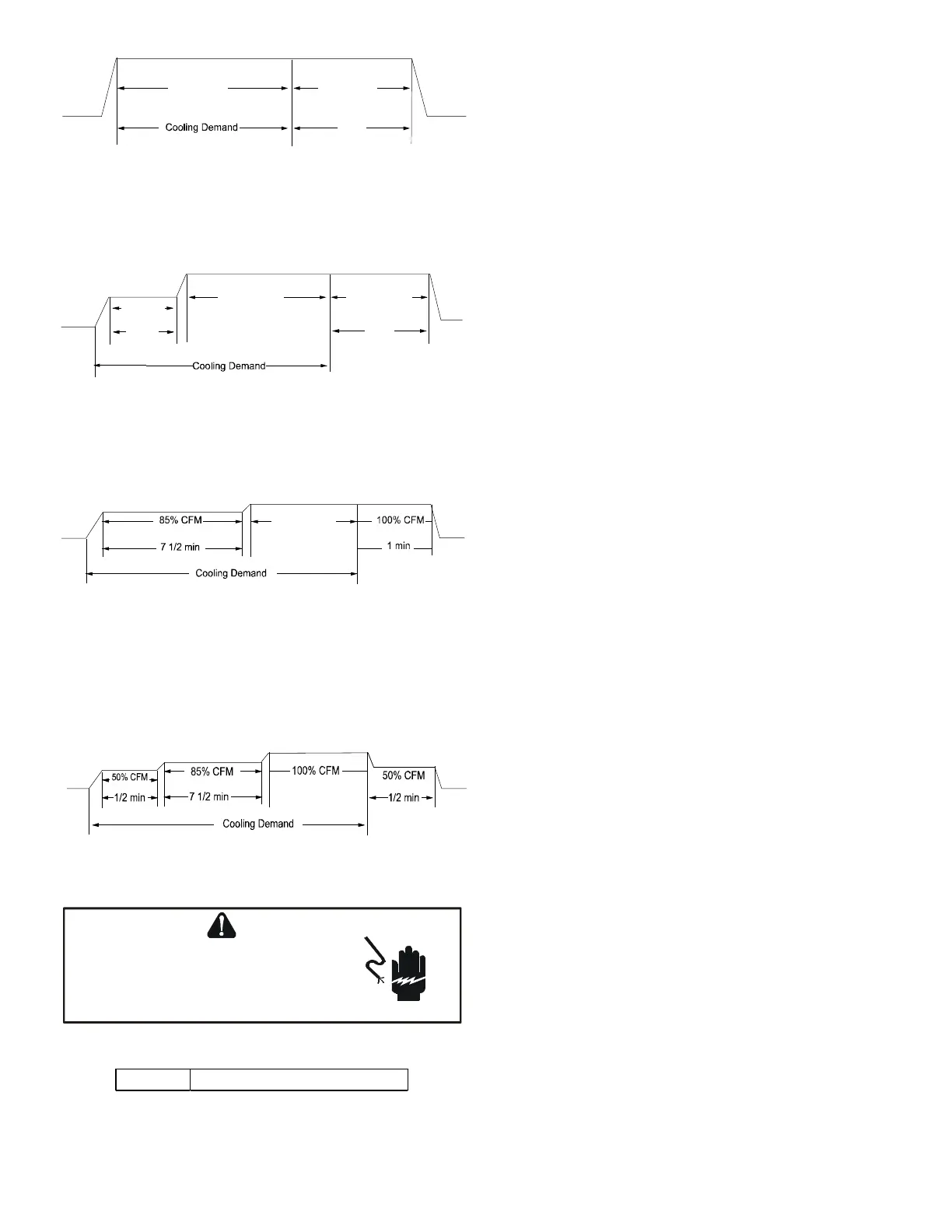

Figure 28

• Prole B (2) ramps up to full cooling demand airow

by rst stepping up to 50% of the full demand for 30

seconds. The motor then ramps to 100% of the required

airow. A one (1) minute OFF delay at 100% of the

cooling airow is provided.

50% CFM

1/2 min

100% CFM

100% CFM

1 min

OFF

OFF

Figure 29

• Prole C (3) ramps up to 85% of the full cooling demand

airow and operates there for approximately 7 1/2

minutes. The motor then steps up to the full demand

airow. Prole C also has a one (1) minute 100% OFF

delay.

Figure 30

• Prole D (4) ramps up to 50% of the demand for 1/2

minute, then ramps to 85% of the full cooling demand

airow and operates there for approximately 7 1/2

minutes. The motor then steps up to the full demand

airow. Prole D has a 1/2 minute at 50% airow OFF

delay.

Figure 31

115 volt line ConneCtion or eleCtroniC Air CleAner

TO AVOID

PERSONAL INJURY OR DEATH, DUE TO

ELECTRICAL SHOCK, DISCONNECT ELECTRICAL POWER

BEFORE SERVICING OR CHANGING ANY ELECTRICAL

WIRING.

WARNING

EAC 1.0 AMP maximum at 120 VAC

The furnace integrated control module is equipped with a line

voltage accessory terminal for controlling power to an option-

al eld supplied electronic air cleaner or any device required

to operate inparallel with a circulating fan demand.

Loading...

Loading...