27

1. Turn OFF gas to furnace at the manual gas shutoff valve

external to the furnace.

2. Turn off all electrical power to the system.

3. Outlet pressure tap connections:

White-Rodgers 36J54 valve: Back outlet pressure

test screw (inlet/outlet pressure tap) out one turn

(counterclockwise, not more than one turn).

4. Attach a hose and manometer to outlet pressure tap .

5. Turn ON the gas supply.

NOTE: Follow this procedure to test the gas valve pressure

at 100% ring rate.

NOTE: the Cool Cloud phone application be used to assist with

all functional tests. See the quick start guide section for details.

The furnace should be inspected by a qualied installer, or

service agency at least once per year. This check should be

performed at the beginning of the heating season. This will

ensure that all furnace components are in proper working or-

der and that the heating system functions appropriately. Pay

particular attention to the following items. Repair or service

as necessary.

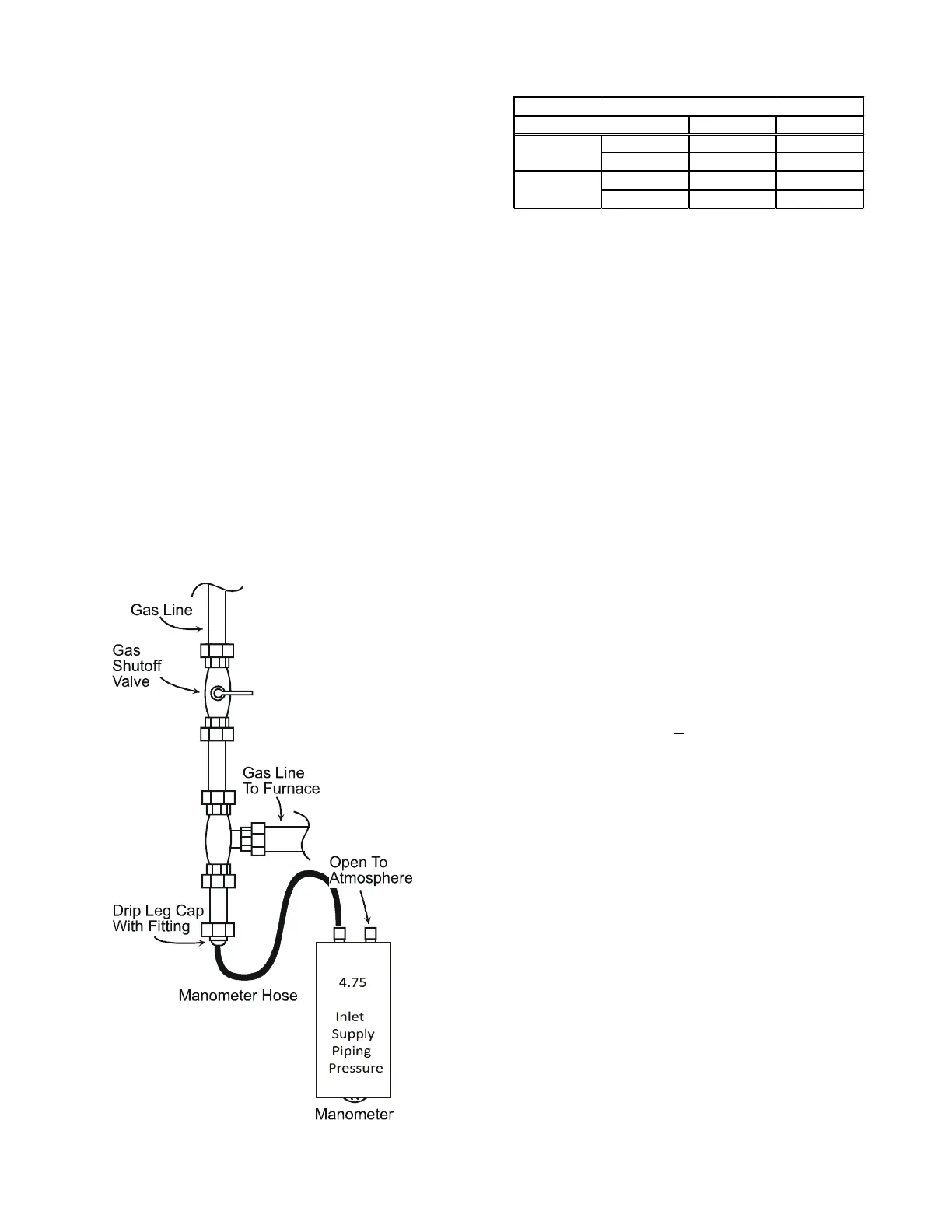

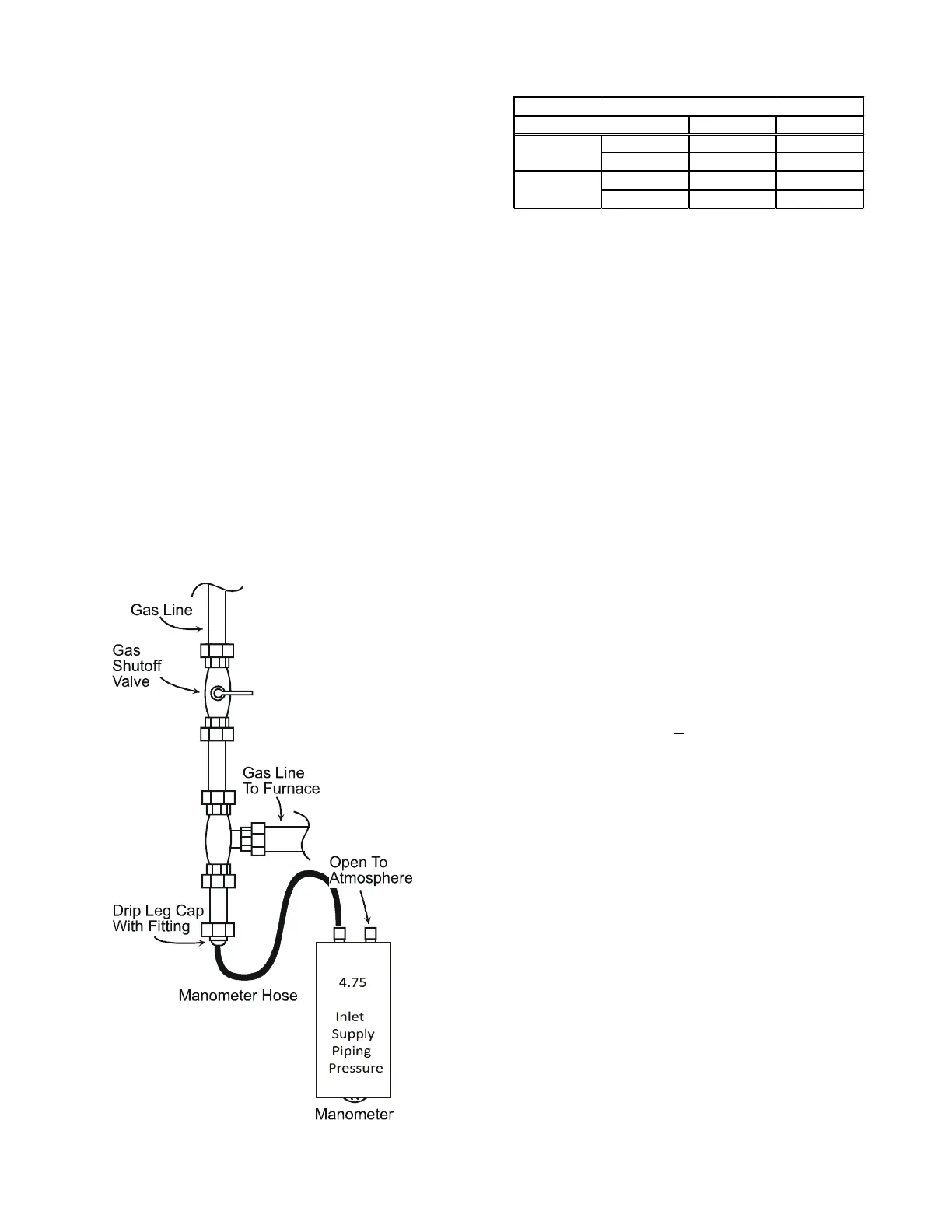

Measuring Inlet Gas Pressure (Alt. Method)

Figure 33

NOTE: When converting from natural gas to L.P. consult

your distributor for proper conversion kit.

Range Nominal

Low Stage 1.6 - 2.2" w.c. 1.9" w.c.

High Stage 3.2 - 3.8" w.c. 3.5" w.c.

Low Stage 5.7 - 6.3" w.c. 6.0" w.c.

High Stage 9.7 - 10.3" w.c. 10.0" w.c.

gAS input rAte meASurement (nAturAl gAS only)

The actual gas input rate to the furnace must never be greater

than that specied on the unit rating plate. To measure natural

gas input using the gas meter, use the following procedure.

1. Turn OFF the gas supply to all other gas-burning appliances

except the furnace.

2. While the furnace is operating at high re rate, time and

record one complete revolution of the gas meter dial,

measuring the smallest quantity, usually the dial that

indicates 1/2 cu. ft. per revolution. You will use this

number to calculate the quantity of gas in cubic ft. if the

furnace would consume if it ran steadily for one hour

(3600 seconds).

3. If the 1/2 cu. ft. dial was used, multiply your number by

two. EXAMPLE: If it takes23 seconds to complete one

revolution of the 1/2 ft. dial (23 x 2 = 46).

This tells us that at this rate, it would take 46 seconds to

consume one cu. ft. of gas. 3600 / 46 = 78.

This tells us that in one hour, the furnace would consume 78

cu. ft. of gas. The typical value range for 1 cu. ft. of natural

gas is around 1000 BTU. Check with your gas utility, if possi-

ble. In this example, the furnace is consuming 78,000 BTUH.

NOTE: The nal manifold pressure cannot vary by more than

± 0.3” w.c. for Natural and + 0.5” for LP from the specied

setting. Consult your local gas supplier if additional input rate

adjustment is required.

4. Turn ON gas to and relight all other appliances

turned off in step 1. Be certain that all appliances

are functioning properly and that all pilot burners are

operating.

temperAture riSe

Temperature rise must be within the range specied on the unit

rating plate. An incorrect temperature rise may result in condensing

in or overheating of the heat exchanger. An airow and tempera-

ture rise table is provided in the Specication Sheet applicable to

your model. Determine and adjust temperature rise as follows:

1. Operate furnace with burners ring for approximately ten

minutes. Ensure all registers are open and all duct dampers

are in their nal (fully or partially open) position.

2. Place thermometers in the return and supply ducts as close

to the furnace as possible. Thermometers must not be

inuenced by radiant heat by being able to “see” the heat

exchanger.

Loading...

Loading...