7

CleArAnCeS And ACCeSSibility

Unobstructed front clearance of 24” for servicing is recom-

mended.

TOP

B1-VENT SINGLE

(PLENUM)

1" 6" 1" 3" 0" 1"

Top clearance for horizontal conguration - 1”

inStAllAtion poSitionS

*MVC80 model furnaces may be installed vertically (upow) or

horizontally with left or right side down. *CVC80 model furnac-

es may be installed vertically (downow) or horizontally with

left or right side down. Do not install this furnace on its back.

For vertically installed upow furnaces, return air ductwork

may be attached to the side panel(s) and/or basepan. For

horizontally installed upow furnaces, return air ductwork must

be attached to the basepan. For counterow furnaces, return

ductwork must be attached to the the blower compartment

end of the furnace.

NOTE: Ductwork must never be attached to the back of the

furnace.

horizontAl inStAllAtion

Line contact to framing is permitted when installed in the hor-

izontal conguration. Line contact is dened as the portion of

the cabinet that is formed by the intersection of the top and

side. ACCESSIBILITY CLEARANCE, WHERE GREATER,

SHOULD TAKE PRECEDENCE OVER MINIMUM FIRE PRO-

TECTION CLEARANCE. A gas-red furnace for installation

in a residential garage must be installed so that the ignition

source and burners are located not less than eighteen inches

(18”) above the oor and is protected or located to prevent

physical damage by vehicles. A gas furnace must not be in-

stalled directly on carpeting, tile, or other combustible materials

other than wood ooring.

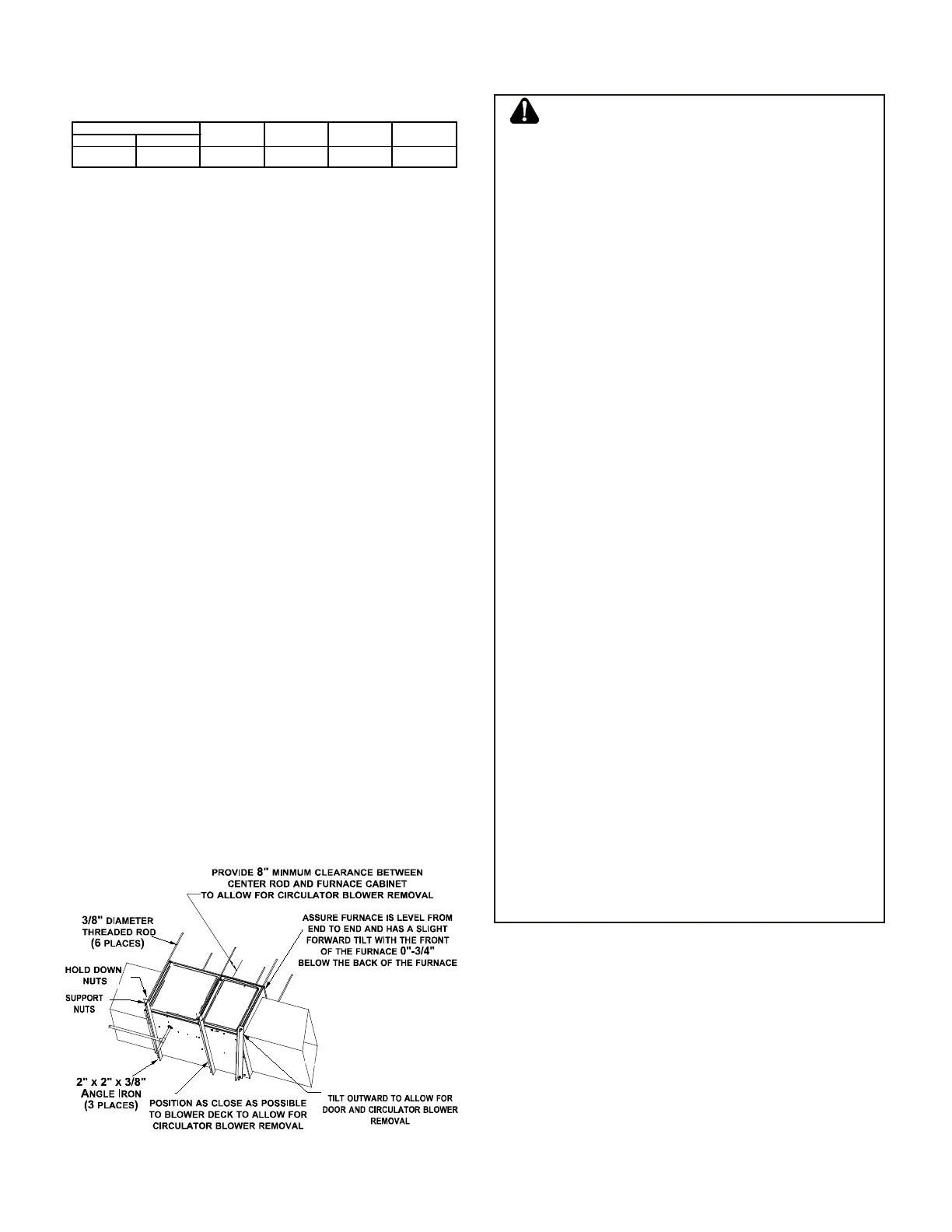

furnACe SuSpenSion

If suspending the furnace from rafters or joist, use 3/8” thread-

ed rod and 2”x2”x3/8” angle iron as shown below. The length

of rod will depend on the application and the clearances

necessary.

Suspended Furnace

Figure 2

exiSting furnACe removAl

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being placed

into operation could result in carbon monoxide poisoning or

death.

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1) Seal any unused openings in the venting system.

2) Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or the Natural Gas and Propane

Installation Code, CSA B149.1 and these instructions.

Determine that there is no blockage or restriction,

leakage, corrosion and other deficiencies which could

cause an unsafe condition.

3) As far as practical, close all building doors and windows

and all doors between the space in which the

appliance(s) connected to the venting system are located

and other spaces of the building.

4) Close fireplace dampers.

5) Turn on clothes dryers and any appliance not connected

to the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are

operating at maximum speed. Do not operate a summer

exhaust fan.

6) Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so

appliance is operating continuously.

7) Test for spillage from draft hood equipped appliances at

the draft hood relief opening after 5 minutes of main

burner operation. Use the flame of a match or candle.

8) If improper venting is observed during any of the above

tests, the venting system must be corrected in

accordance with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or Natural Gas and Propane

Installation Code, CSA B149.1.

9) After it has been determined that each appliance

connected to the venting system properly vents when

tested as outlined above, return doors, windows, exhaust

fans, fireplace dampers and any other gas-fired burning

appliance to their previous conditions of use.

Loading...

Loading...