39

.

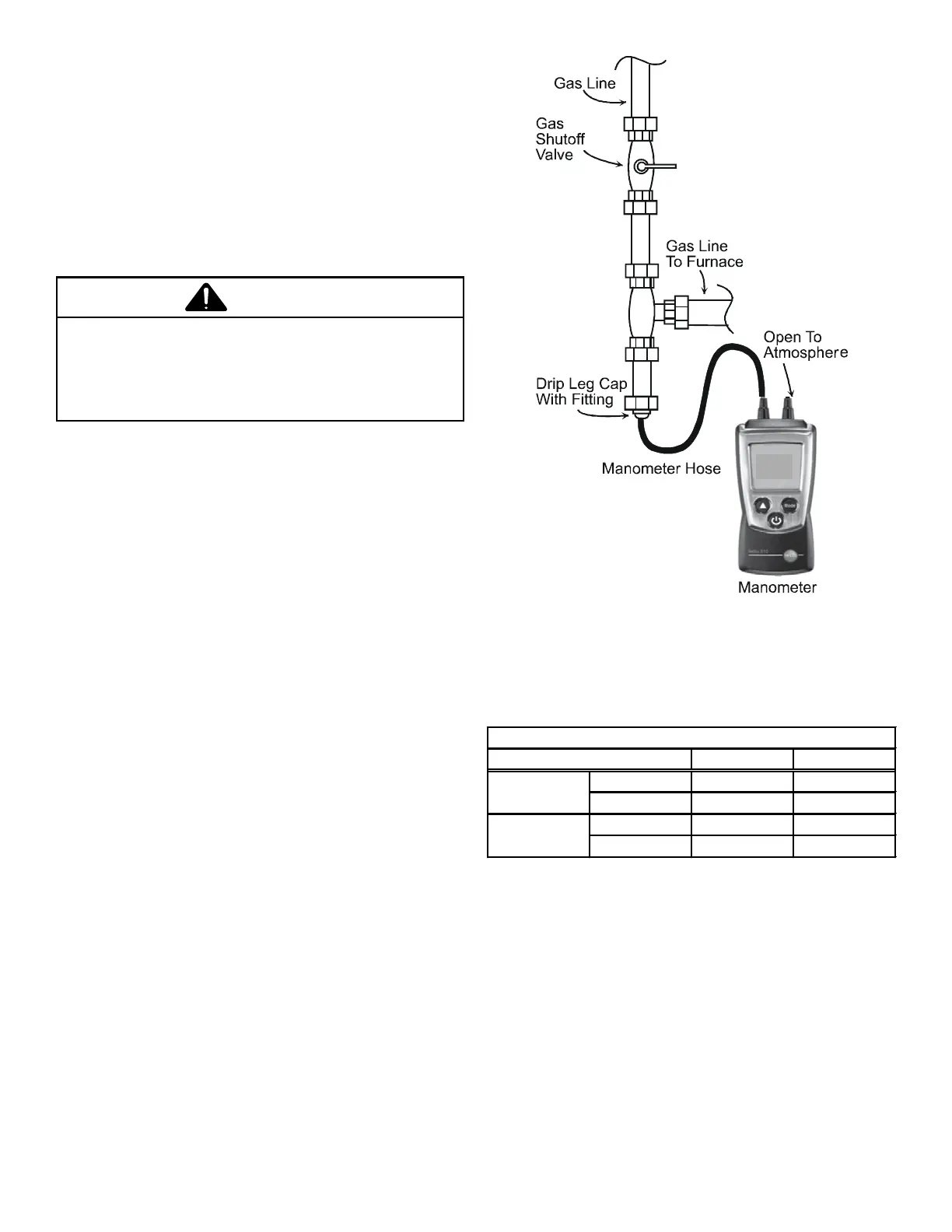

Low Stage 1.6 - 2.2" w .c. 1.9" w .c.

High Stage 3.2 - 3.8" w .c. 3.5" w .c.

Low Stage 5.7 - 6.3" w .c. 6.0" w .c.

High Stage

The actual gas input rate to the furnace must never be

greater than that specied on the unit rating plate. To

measure natural gas input using the gas meter, use the

following procedure.

1. Turn OFF the gas supply to all other gas-burning

appliances except the furnace.

2. While the furnace is operating at high re rate, time

and record one complete revolution of the gas meter

dial, measuring the smallest quantity, usually the dial

If supply pressure diers from table, make the necessary

adjustments to pressure regulator, gas piping size, etc.,

and/or consult with local gas utility.

5. Turn OFF gas to furnace at the manual shuto valve

and disconnect manometer. Reinstall plug before

turning on gas to furnace.

6. Turn OFF any unnecessary gas appliances stated in

step three.

CAUTION

Only small variations in gas pressure should be made by

adjusting the gas valve pressure regulator. The manifold

pressure must be measured with the burners operating.

To measure and adjust the manifold pressure, use the

following procedure.

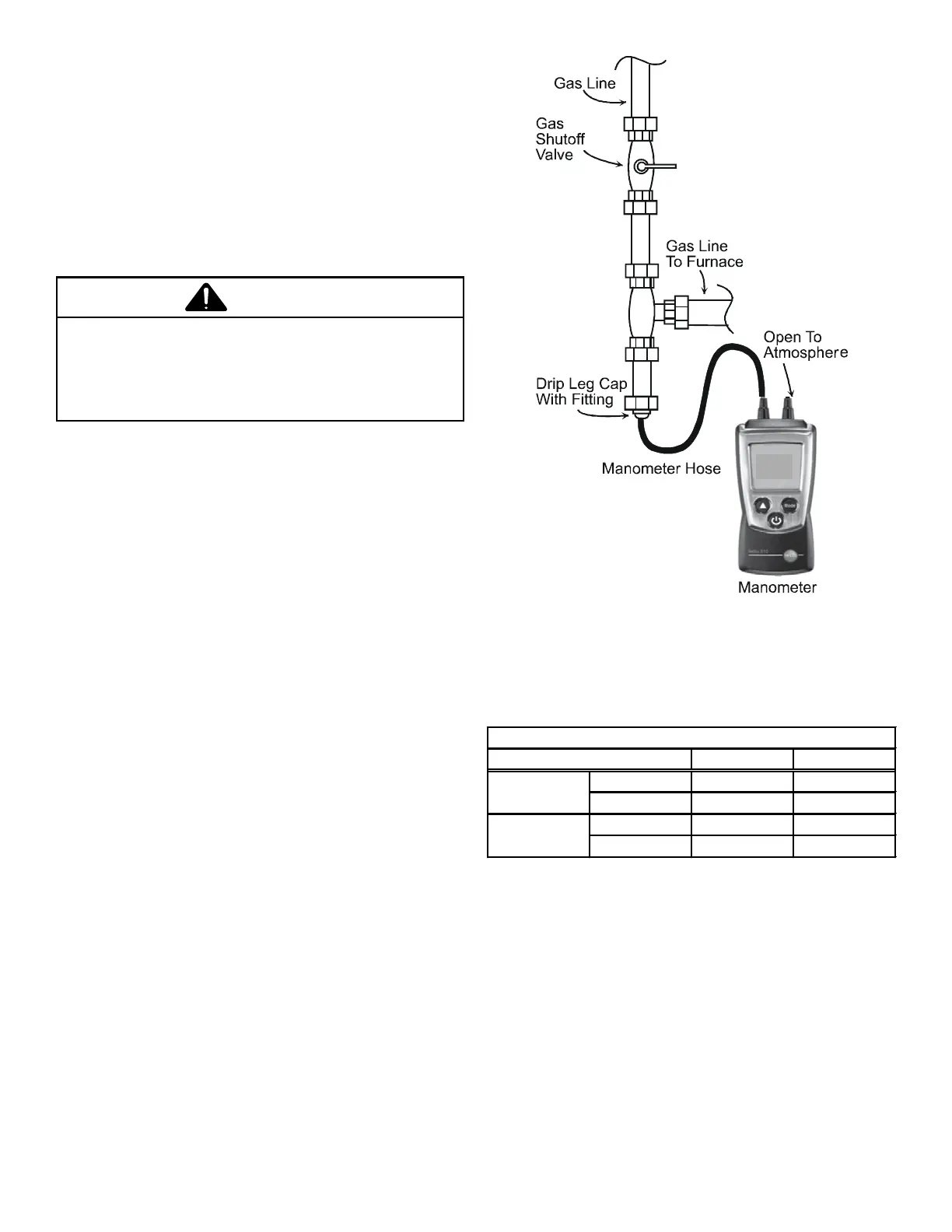

1. Turn OFF gas to furnace at the manual gas shuto

valve external to the furnace.

2. Turn o all electrical power to the system.

3. Outlet pressure tap connections:

White-Rodgers 36J54 valve: Back outlet pressure

test screw (inlet/outlet pressure tap) out one turn

(counterclockwise, not more than one turn).

4. Attach a hose and manometer to outlet pressure tap .

5. Turn ON the gas supply.

The furnace should be inspected by a qualied installer, or

service agency at least once per year. This check should

be performed at the beginning of the heating season.

This will ensure that all furnace components are in proper

working order and that the heating system functions

appropriately. Pay particular attention to the following

items. Repair or service as necessary.

Loading...

Loading...