4

1

2

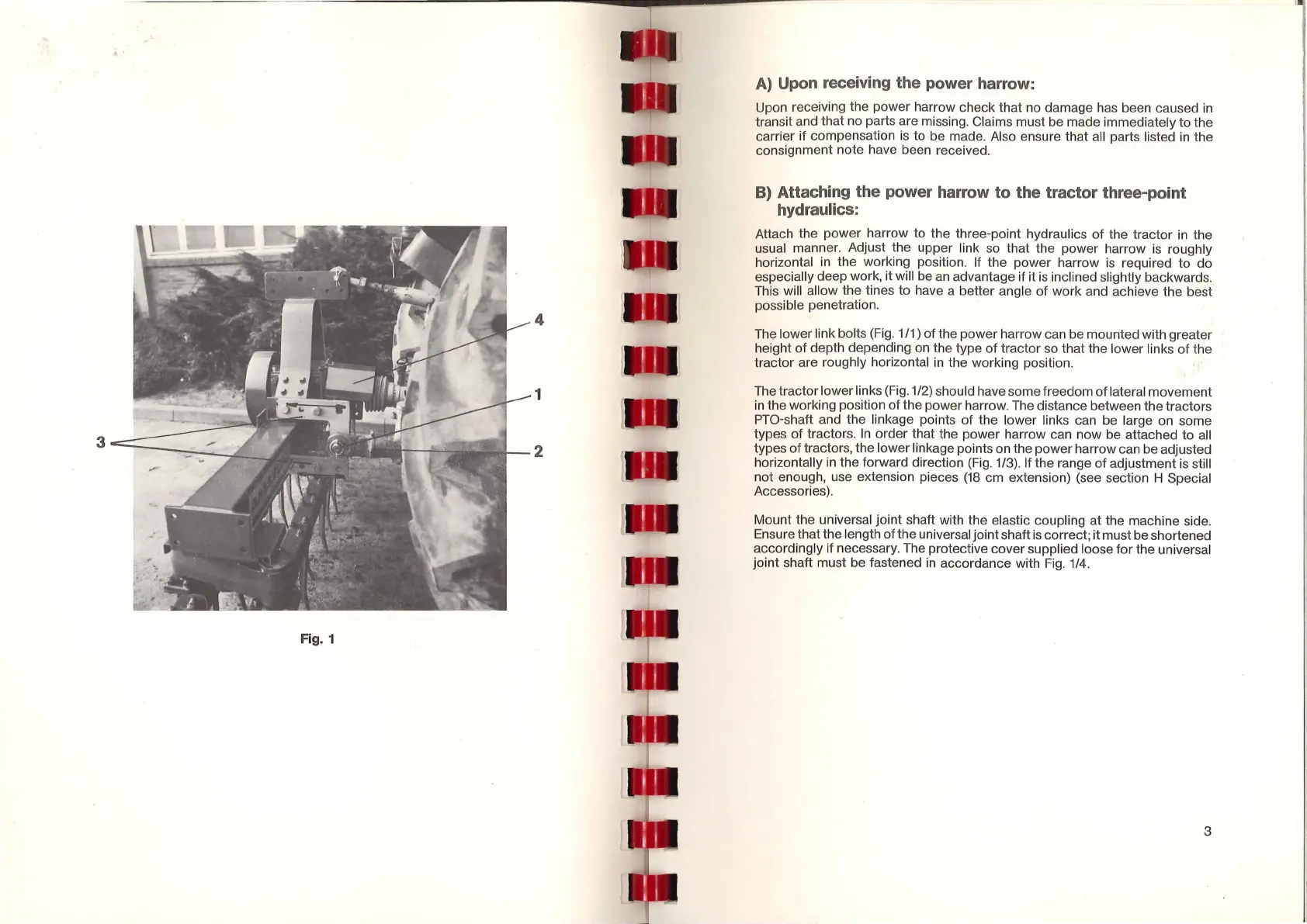

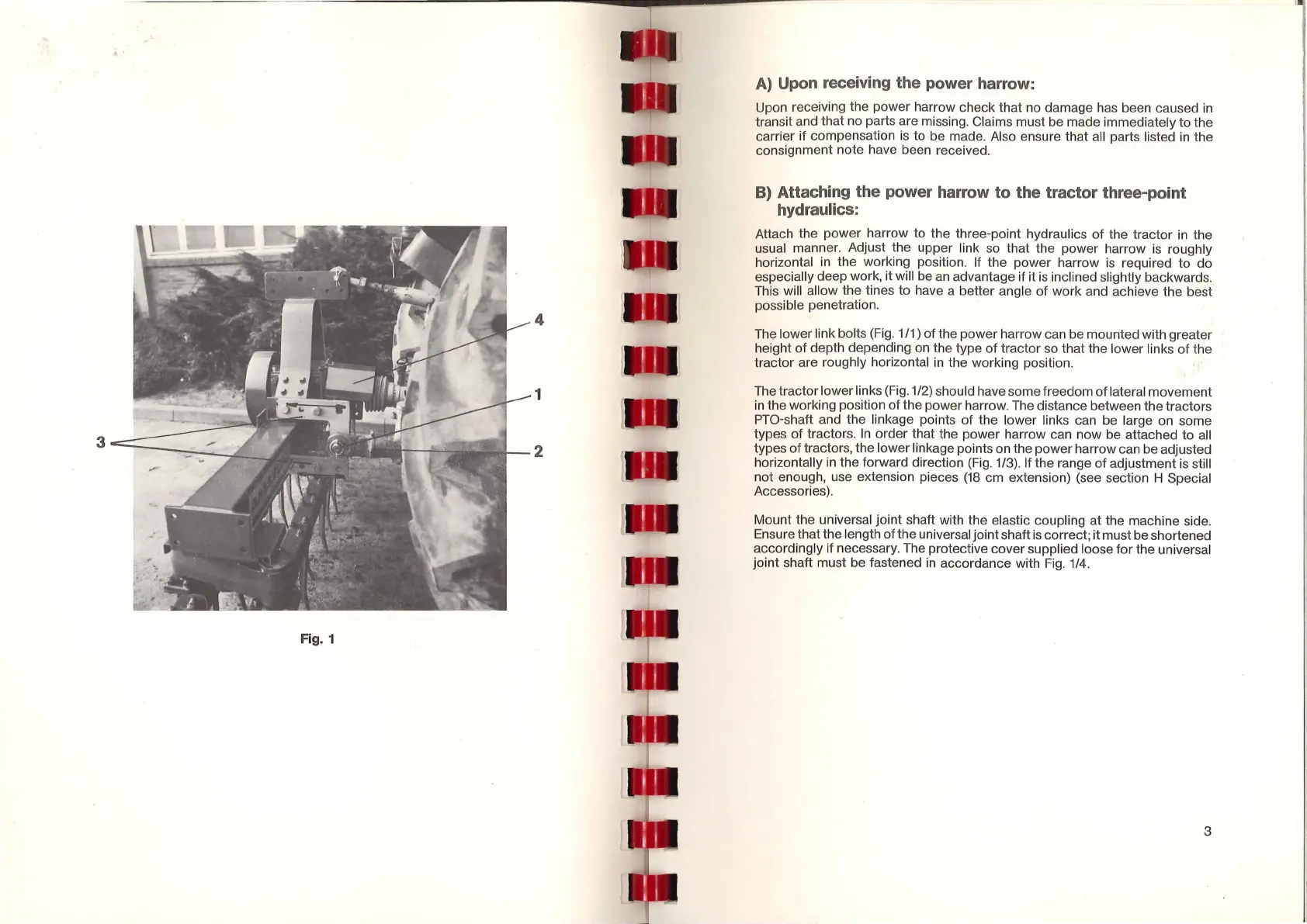

Fig. 1

A}

Upon receiving the power harrow:

Upon receiving the power harrow check that no damage

has

been caused

in

transit and that no parts are missing. Claims must be made immediately to the

carrier if compensation

is

to be made. Also ensure that all parts listed

in

the

consignment note have been received.

B}

Attaching the power harrow

to

the tractor three-point

hydraulics:

Attach the power harrow to the three-point hydraulics

of

the tractor

in

the

usual manner. Adjust the upper link

so

that the power harrow

is

roughly

horizontal

in

the working position. If the power harrow

is

required to do

especially deep work, it will

be

an

advantage if it

is

inclined slightly backwards.,

This will allow the tines to have a better angle of work and achieve the best

possible penetration.

The lower link bolts

(Fig.

1 /1)

of

the power harrow can be mounted with greater

height

of

depth depending

on

the type

of

tractor

so

that the lower links

of

the

tractor are roughly horizontal

in

the working position.

The tractor lower links

(Fig.

1/2) should have some freedom

of

lateral movement

in

the working position of the power harrow. The distance between the tractors

PTO-shaft and the linkage points

of

the lower links can

be

large on some

types

of

tractors.

In

order that the power harrow can now be attached to all

types

of

tractors, the lower linkage points on the power harrow can be adjusted

horizontally

in

the forward direction

(Fig

. 1/3). If the range

of

adjustment

is

still

not enough, use extension pieces

(18

cm extension) (see section H Special

Accessories).

Mount the universal joint shaft with the elastic coupling at the machine side.

Ensure that the length of the universal joint shaft

is

correct; it must be shortened

accordingly if necessary. The protective cover supplied loose for the universal

joint shaft must be fastened

in

accordance with

Fig.

1/4.

3

Loading...

Loading...