8

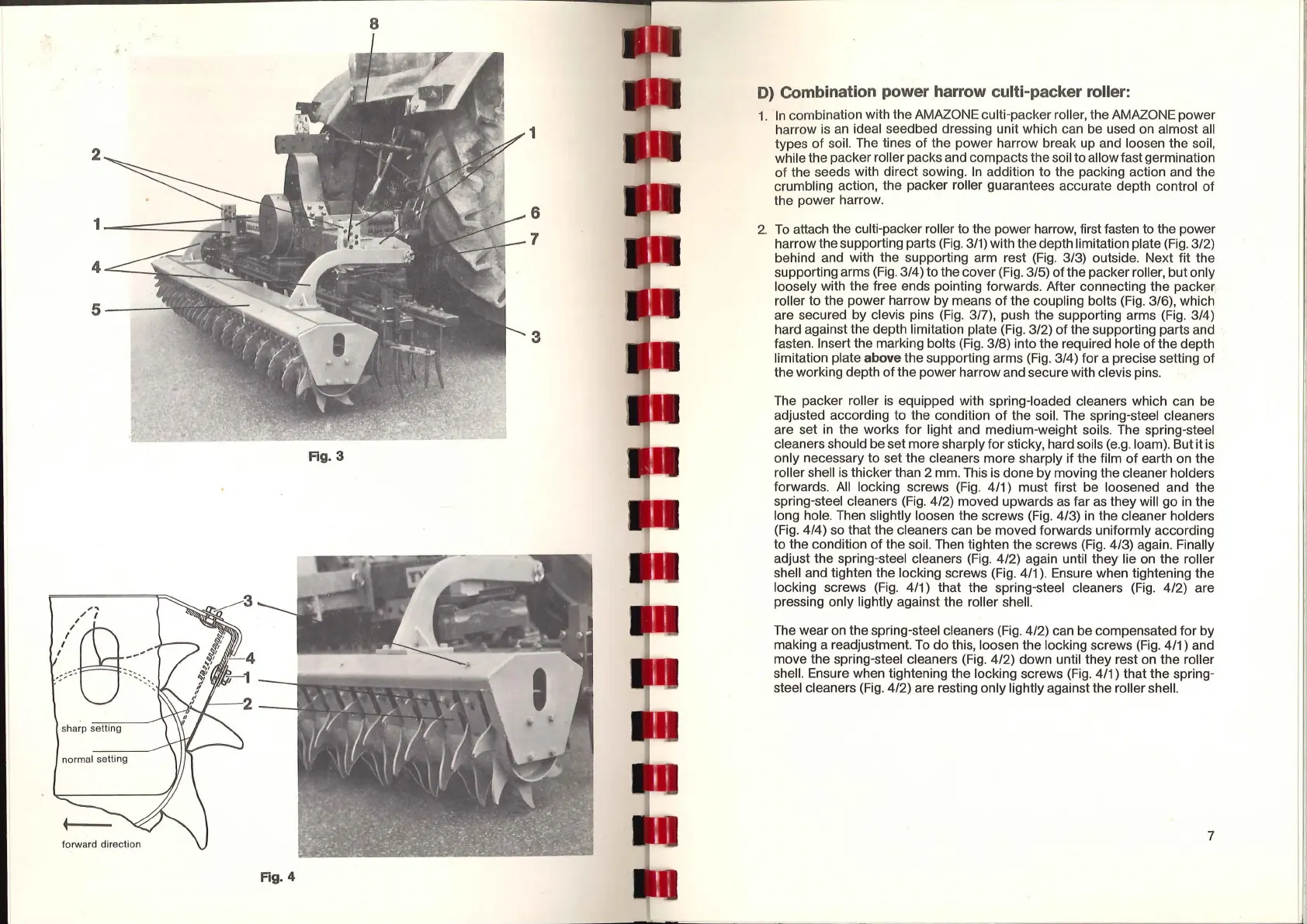

Fig. 3

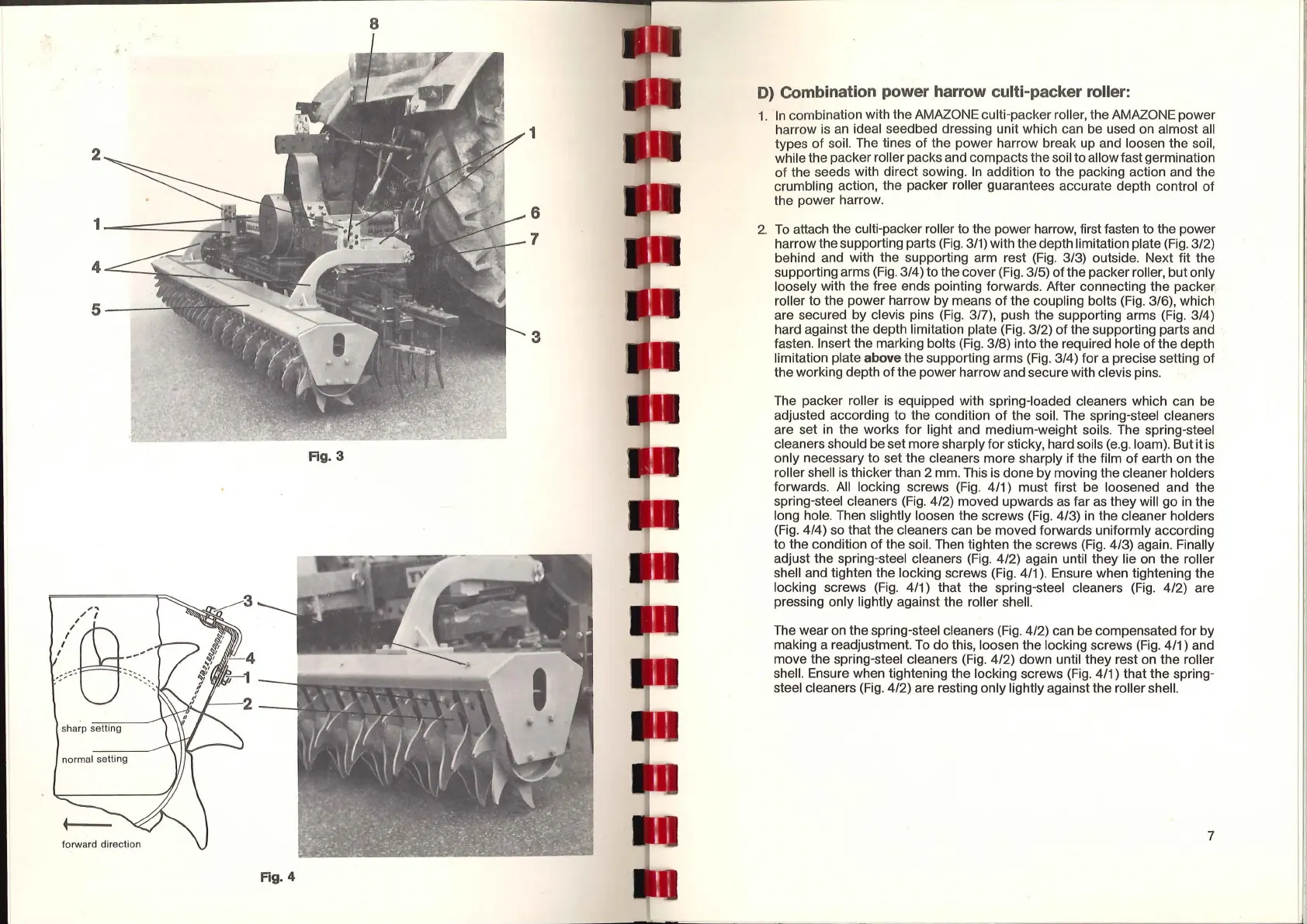

sharp setting

normal setting

forward direction

Fig. 4

1

6

7

3

D) Combination power harrow culti-packer roller:

1.

·

In

combination with the AMAZONE culti-packer roller, the AMAZONE power

harrow

is

an

ideal seedbed dressing unit which can be used on almost all

types

of

soil. The tines

of

the power harrow break up and loosen the soil,

while the packer roller packs and compacts the soil to allow fast germination

of

the seeds with direct sowing.

In

addition to the packing action and the

crumbling action, the packer roller guarantees accurate depth control

of

the power harrow.

2.

To

attach the culti-packer roller to the power harrow, first fasten to the power

harrow the supporting parts

(Fig.

3/1)

with the depth limitation plate (Fig. 3/2)

behind and with the supporting arm rest (Fig. 3/3) outside. Next fit the

supporting arms

(Fig.

3/4) to the cover (Fig. 3/5)

of

the packer roller, but only

loosely with the free ends pointing forwards. After connecting the packer

roller to the power harrow

by

means

of

the coupling bolts (Fig. 3/6), which

are secured by clevis pins (Fig. 3/7), push the supporting arms (Fig. 3/4)

hard against the depth limitation plate (Fig. 3/2)

of

the supporting parts and

fasten. Insert the marking bolts

(Fig.

3/8) into the required hole

of

the depth

limitation plate

above the supporting arms

(Fig.

3/4)

for

a precise setting

of

the working depth of the power harrow and secure with clevis pins.

The packer roller

is

equipped with spring-loaded cleaners which can be

adjusted according to the condition

of

the soil. The spring-steel cleaners

are set

in

the works for light and medium-weight soils. The spring-steel

cleaners should be set more sharply

for

sticky, hard soils (e.g. loam). But it

is

only necessary to set the cleaners more sharply if the film

of

earth on the

roller shell

is

thicker than 2 mm. This

is

done

by

moving the cleaner holders

forwards.

All

locking screws (Fig. 4/1) must first be loosened and the

spring-steel cleaners (Fig. 4/2) moved upwards

as

far

as

they will go

in

the

long hole. Then slightly loosen the screws (Fig. 4/3)

in

the cleaner holders

(Fig.

4/4) so that the cleaners can be moved forwards uniformly according

to the condition

of

the soil. Then tighten the screws (Fig. 4/3) again. Finally

adjust the spring-steel cleaners (Fig. 4/2) again until they lie

on

the roller

shell and tighten the locking screws (Fig.

4/1

).

Ensure when tightening the

locking screws

(Fig.

4/1) that the spring-steel cleaners

(Fig.

4/2) are

pressing only lightly against the roller shell.

The wear on the spring-steel cleaners (Fig. 4/2) can be compensated for

by

making a readjustment.

To

do this, loosen the locking screws (Fig. 4/1) and

move the spring-steel cleaners (Fig. 4/2) down until they rest on the roller

shell. Ensure when tightening the locking screws

(Fig.

4/1) that the spring-

steel cleaners (Fig. 4/2) are resting only lightly against the roller shell.

7

Loading...

Loading...