1

Ag. 7

1

Ag. 8

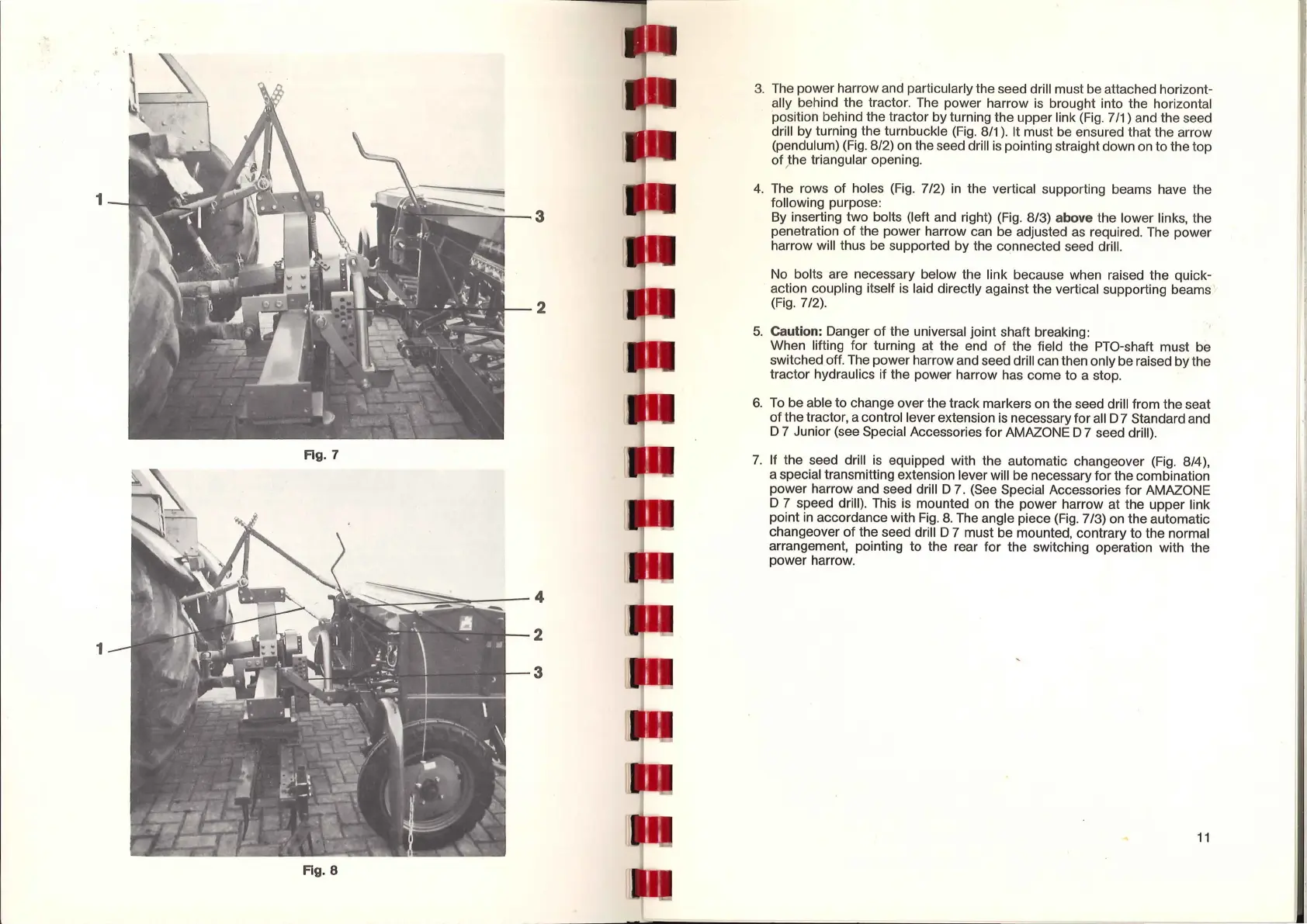

3.

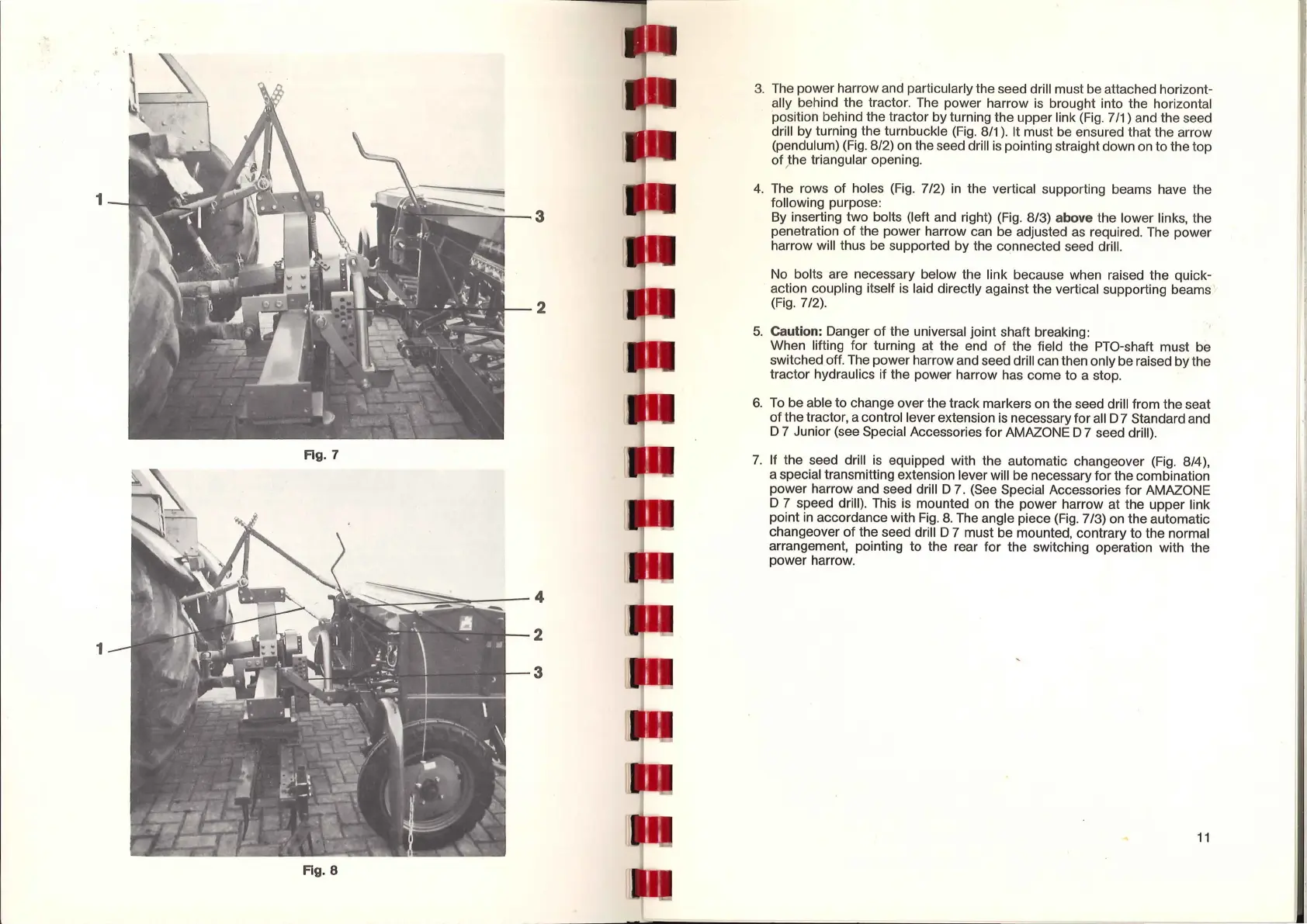

The power harrow and particularly the seed drill must be attached horizont-

ally behind the tractor.

The

power harrow

is

brought into the horizontal

·position behind the tractor by turning the upper link

(Fig.

7 /1) and the seed

drill by turning the turnbuckle

(Fig.

8/1

).

It must be ensured that the arrow

(pendulum)

(Fig.

8/2)

on

the seed drill

is

pointing straight down

on

to the top

of

J

he

triangular opening.

4. The rows of holes

(Fig.

7 /2)

in

the vertical supporting beams have the

following purpose:

By

inserting two bolts (left and right)

(Fig.

8/3) above the lower links, the

penetration of the power harrow can be adjusted

as

required. The power

harrow will thus be supported by the connected seed drill.

No

bolts are necessary below the link because when raised the quick-

action coupling itself

is

laid directly against the vertical supporting beams '

(Fig.

7/2).

5.

Caution: Danger

of

the universal joint shaft breaking:

When lifting for turning at the end

of

the field the PTO-shaft must be

switched off. The power harrow and seed drill can then only be raised by the

tractor hydraulics if the power harrow has come to a stop.

6.

To

be able to change over the track markers

on

the seed drill from the seat

of the tractor, a control lever extension

is

necessary for

all

D 7 Standard and

D 7 Junior (see Special Accessories for AMAZONE D 7 seed drill).

7.

If the seed drill

is

equipped with the automatic changeover

(Fig.

8/4

),

a special transmitting extension lever will be necessary for the combination

power harrow and seed drill D 7.

(See

Special Accessories for AMAZONE

D 7 speed drill). This

is

mounted

on

the power harrow at the upper link

point

in

accordance with

Fig.

8.

The angle piece

(Fig.

7 /3)

on

the automatic

changeover

of

the seed drill D 7 must be mounted, contrary to the normal

arrangement, pointing to the rear for the switching operation with the

power harrow.

11

Loading...

Loading...