PAGE 4 Pub. No. 11-AC11D2-5

INSTALLER'S GUIDE

7. Table 1 defines maximum total length of low voltage wiring

from outdoor unit, to indoor unit, and to thermostat.

8. Mount the indoor thermostat in accordance with instruction

included with the thermostat. Wire per appropriate hookup

diagram (included in these instructions).

G. COMPRESSOR START UP

After all electrical wiring is complete, SET THE THERMOSTAT

SYSTEM SWITCH IN THE OFF POSITION SO COMPRESSOR

WILL NOT RUN, and apply power by closing the system main

disconnect switch. This will activate the compressor sump heat

(where used). Do not change the Thermostat System Switch

until power has been applied for one (1) hour. Following this

procedure will prevent potential compressor overload trip at the

initial start-up.

H. OPERATIONAL AND CHECKOUT PROCEDURES

Final phases of this installation are the unit Operational and

Checkout Procedures which are found in this instruction on page 8.

To obtain proper performance, all units must be operated and

charge adjustments made in accordance with procedures found

in the Service Facts.

I. ELECTRIC HEATERS

Electric heaters, if used, are to be installed in the air handling

device according to the instructions accompanying the air han-

dler and the heaters.

J. START CONTROL

Some models have quick start components which are factory

installed. For models that do not have factory installed start

components, provisions are made for a field installed start kit

accessory. When adding an accessory, follow the instructions

provided with the kit.

K. OUTDOOR THERMOSTAT

An outdoor thermostat TAYSTAT250B may be field installed.

For data, see wiring diagram attached to unit and instruction

sheet packaged with outdoor thermostat.

L. SEACOAST SALT SHIELD

The 2A7A4 & 2A7A5 models are shipped with a black Seacoast

Salt Shield. The 2A7A2 & 2A7A1 units installed within one mile

of salt water, including seacoasts and inland waterways, require

the addition of BAYSEAC001 (Seacoast Kit) at the time of

installation.

IMPORTANT: See Limited Warranty information in Use

and Care Manual.

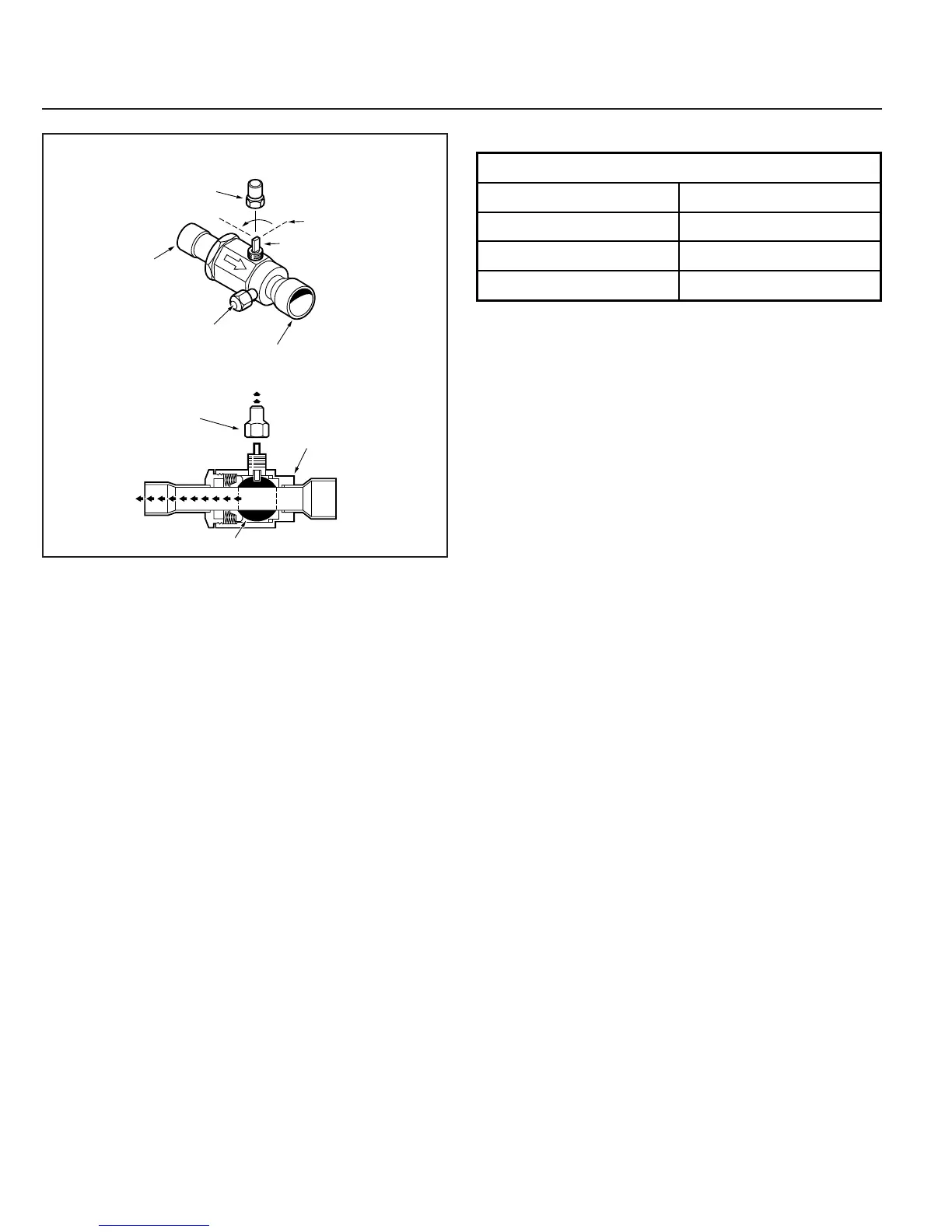

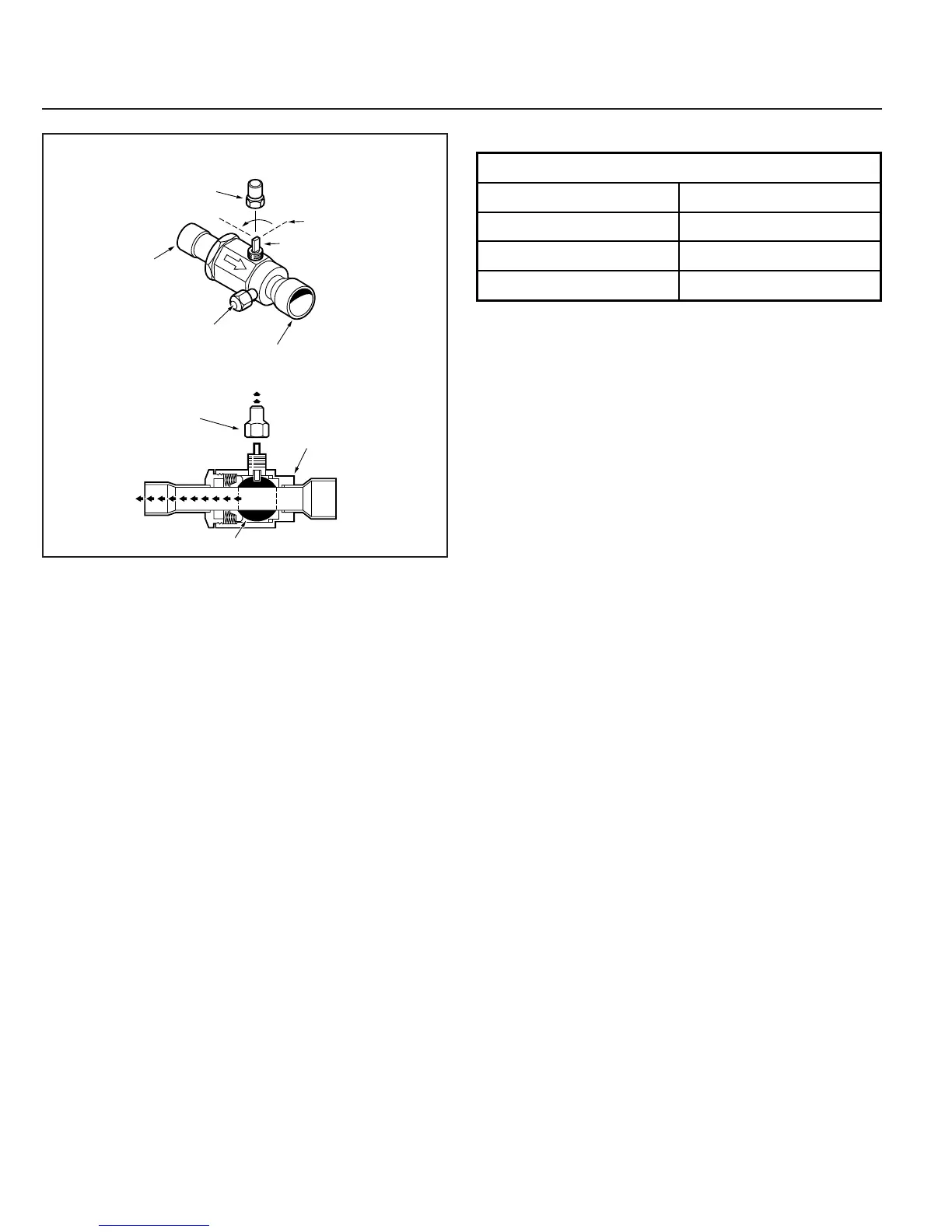

10. Replace liquid service pressure tap port cap and valve stem

cap. These caps MUST BE REPLACED to prevent leaks.

Replace valve stem and pressure tap cap finger tight, then

tighten an additional 1/6 turn.

11. The gas valve can now be opened. Open the gas valve by

removing the shut-off valve cap and turning the valve stem

1/4 turn counterclockwise, using 1/4" Open End or Adjustable

wrench. See Figure 5.

12. The gas valve is now open for refrigerant flow. Replace valve

stem cap to prevent leaks. Again, these caps MUST BE RE-

PLACED to prevent leaks. Replace valve stem and pressure tap

cap finger tight, then tighten an additional 1/6 turn. See Figure 5.

If refrigerant lines are longer than 15 feet and/or a different size

than recommended, it will be necessary to adjust system

refrigerant charge upon completion of installation. See unit

Service Facts.

F. ELECTRICAL CONNECTIONS

▲ WARNIN

:

When installing or servicing

this equipment, ALWAYS exercise basic safety precau-

tions to avoid the possibility of electric shock.

1. Power wiring and grounding of equipment must comply with

local codes.

2. Power supply must agree with equipment nameplate.

3. Install a separate disconnect switch at the outdoor unit.

4. Ground the outdoor unit per local code requirements.

5. Provide flexible electrical conduit whenever vibration trans-

mission may create a noise problem within the structure.

6. The use of color coded low voltage wire is recommended to

simplify connections between the outdoor unit, the thermostat

and the indoor unit.

Table 1 — NEC Class II Control Wiring

CAP

1/4 TURN ONLY

COUNTERCLOCKWISE

FOR FULL OPEN

POSITION

VALVE STEM

GAS LINE CONNECTION

UNIT SIDE

OF VALVE

CAP

BODY

COOLING

CORE

PRESSURE TAP PORT

GAS LINE BALL SERVICE VALVE

5

24 VOLTS

WIRE SIZE MAX. WIRE LENGTH

18 AWG 150 FT

16 AWG 225 FT.

14 AWG 300 FT.

Loading...

Loading...