Model 415

Operation Manual

3. The Weld Current calibration schedule will be run in WELD

Mode and will contain the following:

Onelevel Functions

Prepurge 10 Torch Gas Rate 40*

Upslope 1.0 Start Level 25

Num Starts 1

Postpurge 20 Level Advance Manual

Downslope 5.0 Stubout Mode On*

Start Mode Touch*

Multilevel Level 1 Functions

Pri Amps 200 Bck Pulse

10.0

Bck Amps 200 Pulse Mode OFF

Pri Pulse 10.0 Travel Step OFF

Multilevel Level 2 Functions

Pri Amps 400* Bck Pulse

10.0

Bck Amps 400* Pulse Mode OFF

Pri Pulse 10.0 Travel Step OFF

*Maximum torch value of 300 amps – use 300 amps here. Step 5.6-6-9 value would then be

3.75 VDC +/- 0.037 VDC.

4. Level Time will be in the Manual Mode requiring the operator to Sequence stop the M-415

after measurements and any required adjustments are done. Pulse Mode should be OFF so

only the Primary Current Amps is checked. The Primary Amps should be set to 200 for the

Initial measurement. Insure that the Travel Mode switch is set to OFF. It is very important

the calibration measurements are done quickly, so not to melt the work piece. A suggestion

is to make the necessary connections to the PCB test points and disconnect the test

leads at the DMM until an arc is established.

5. Recall from the LIBRARY the appropriate Calibration Weld Schedule.

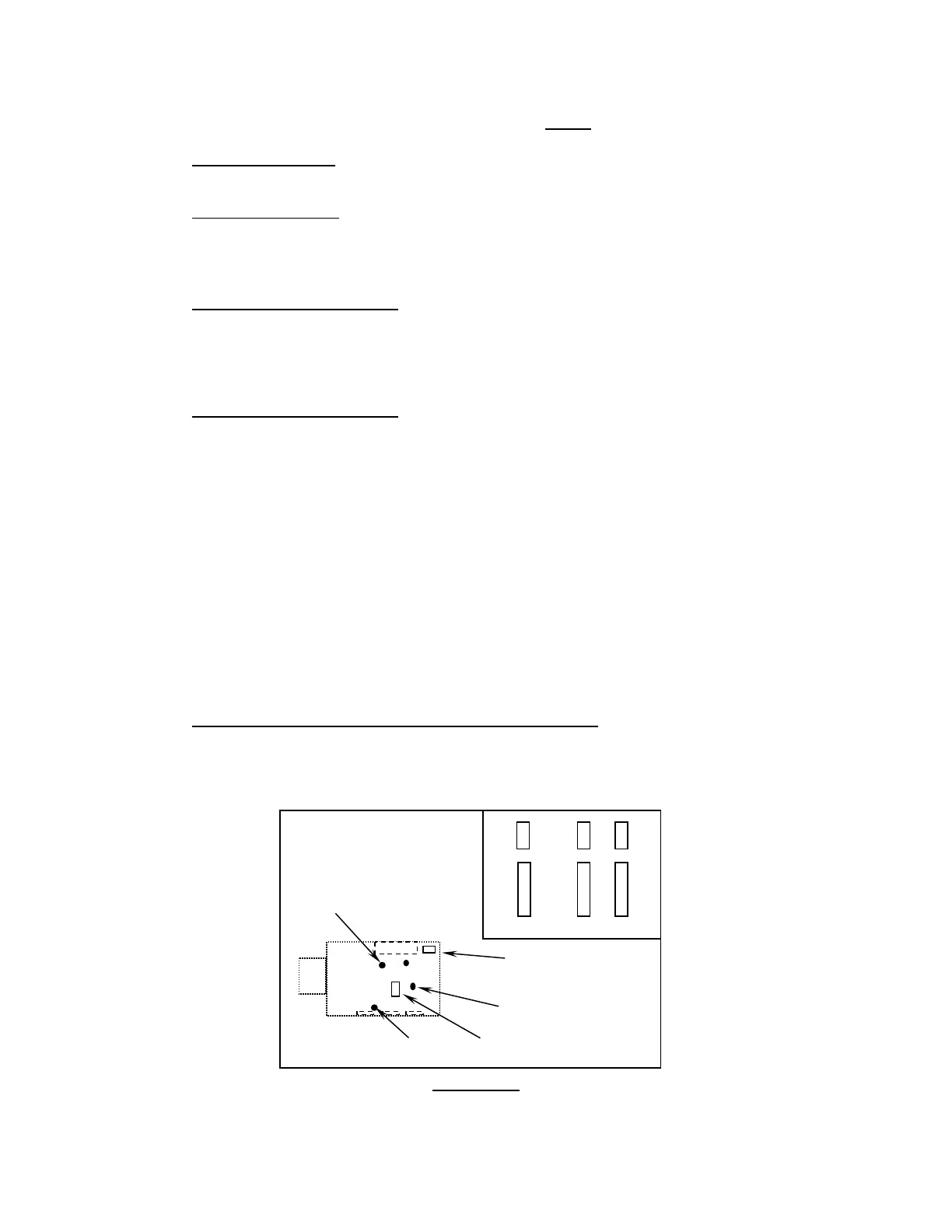

6. CURRENT CALIBRATION WITHOUT EXTERNAL SHUNT

1. Connect the negative test lead to TP-2 and the positive test lead to TP-1 of the weld

current servo. The Current Servo (P/N 13D150300-01) can be accessed through an

opening in the upper deck plate just below the Interface PCB.

TP-1

R-39 DO NOT ADJUST

FACTORY PRESET

INTERFACE A 0/1 B 0/1

TP-2

TP-3

R36

DIAGRAM 3

Docum

e

nt No. 740084

Revision N

33

Loading...

Loading...