3.1 Description

The APH 5020/5030/6020/6530/100-20 are reversible vibrating

plates operating on the basis of the twin-shaft resp. three-shaft

vibration system principle. The Engine drives the exciter on the

baseplate via hydraulic components.

The exciter produces the vibration required for compaction owing

to the incorporated out-of-balance weights.

The machine is guided at the tow-bar grip. It is operated with the

operating controls on the tow-bar.

The APH 5020/5030/6020/6530/100-20 are suitable for all heavy

compaction work in the fileds of civil Engineering and road con-

struction.

It can be used to compact all ground materials such as sand,

gravel, slag, crushed stone, asphalt and composite sett paving.

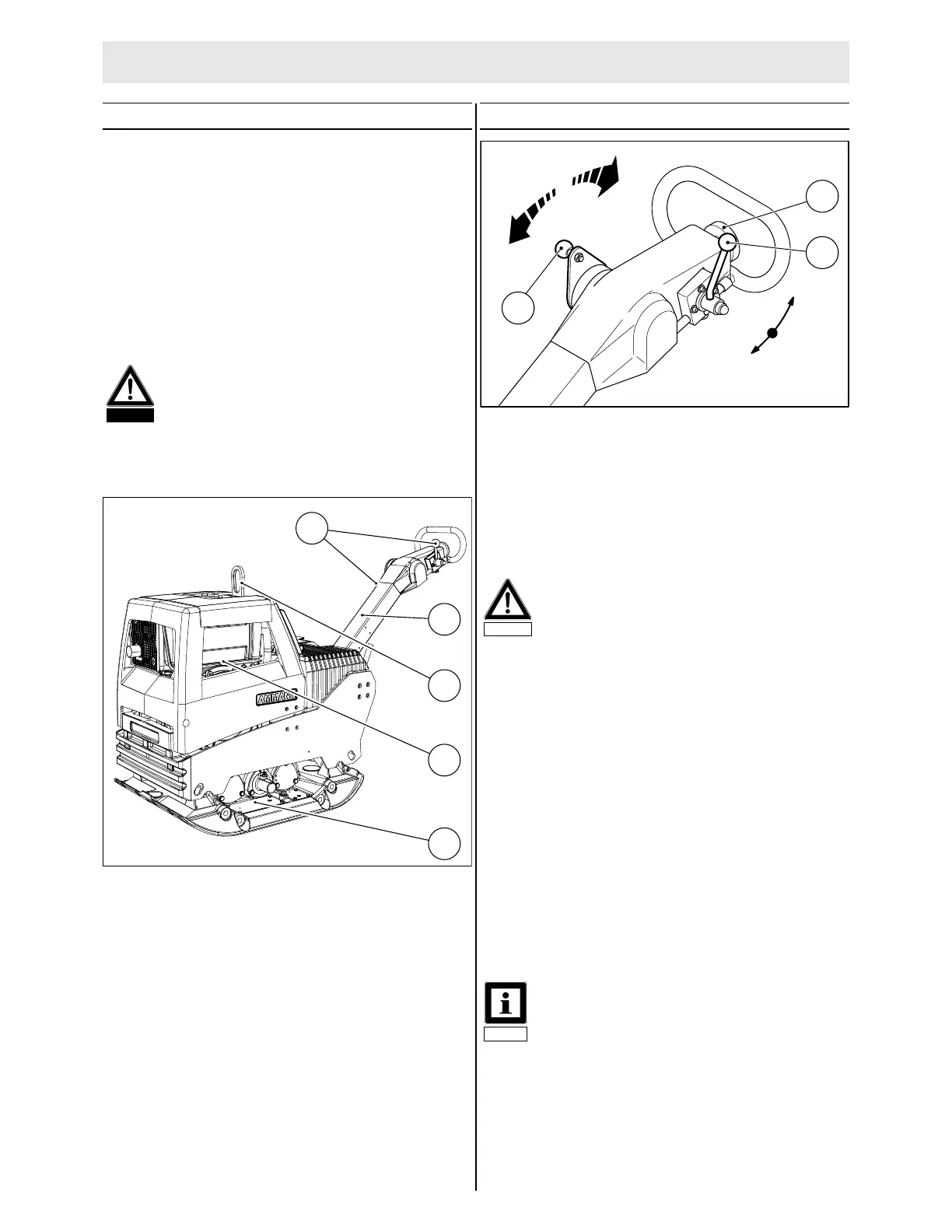

3.1.1 Overview of components

1 Baseplate with exciter

2 Engine

3 Central-point suspension

4 Tow-bar

5 Operating controls / tow-bar

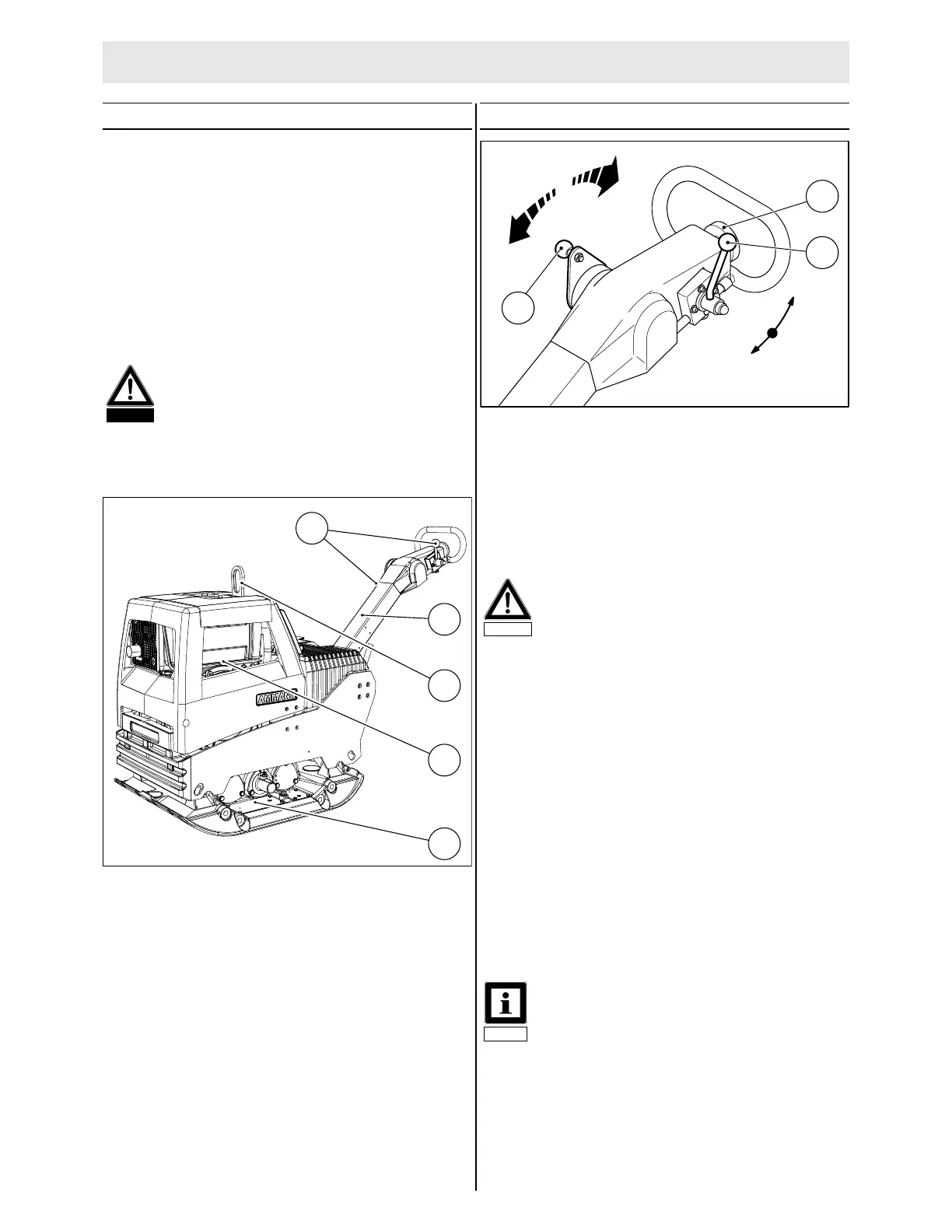

3.2 Operating controls on the tow-bar

1 Engine speed control lever

0 Engine stop

I Idle (detent position)

II Full load

The Engine speed can be adjusted steplessly with the control le-

ver. At minimum Engine speed (I), the drive to the exciter is dis-

connected at the centrifugal clutch and the Engine idles.

The centrifugal clutch engages when the control lever is moved

approximately ¼ of its adjustment travel.

2 Drive lever

a Forward

b Reverse

The drive lever serves to adjust the movements in the exciter and

therefore provides a stepless control

• of the travel direction forwards (a) / backwards (b)

• of the speed

3 Emergency stop connection

1)

The emergency stop switch serves to immediately halt the ma-

chine in emergency situations.

Once the switch knob is pressed the power transmission is inter-

rupted and the machine itself stops though the Engine continues

to run.

Following the pressing of the switch during operation:

• The switch is released by withdrawing it.

• Normal operation can then be immediately resumed. (The

travel direction and speed do not need to be reselected).

1)

APH 5020/5030/6020/6530: Special equipment

3. Operation

33

Loading...

Loading...