204 ASC 110

23. Check the tightening of bolted connections

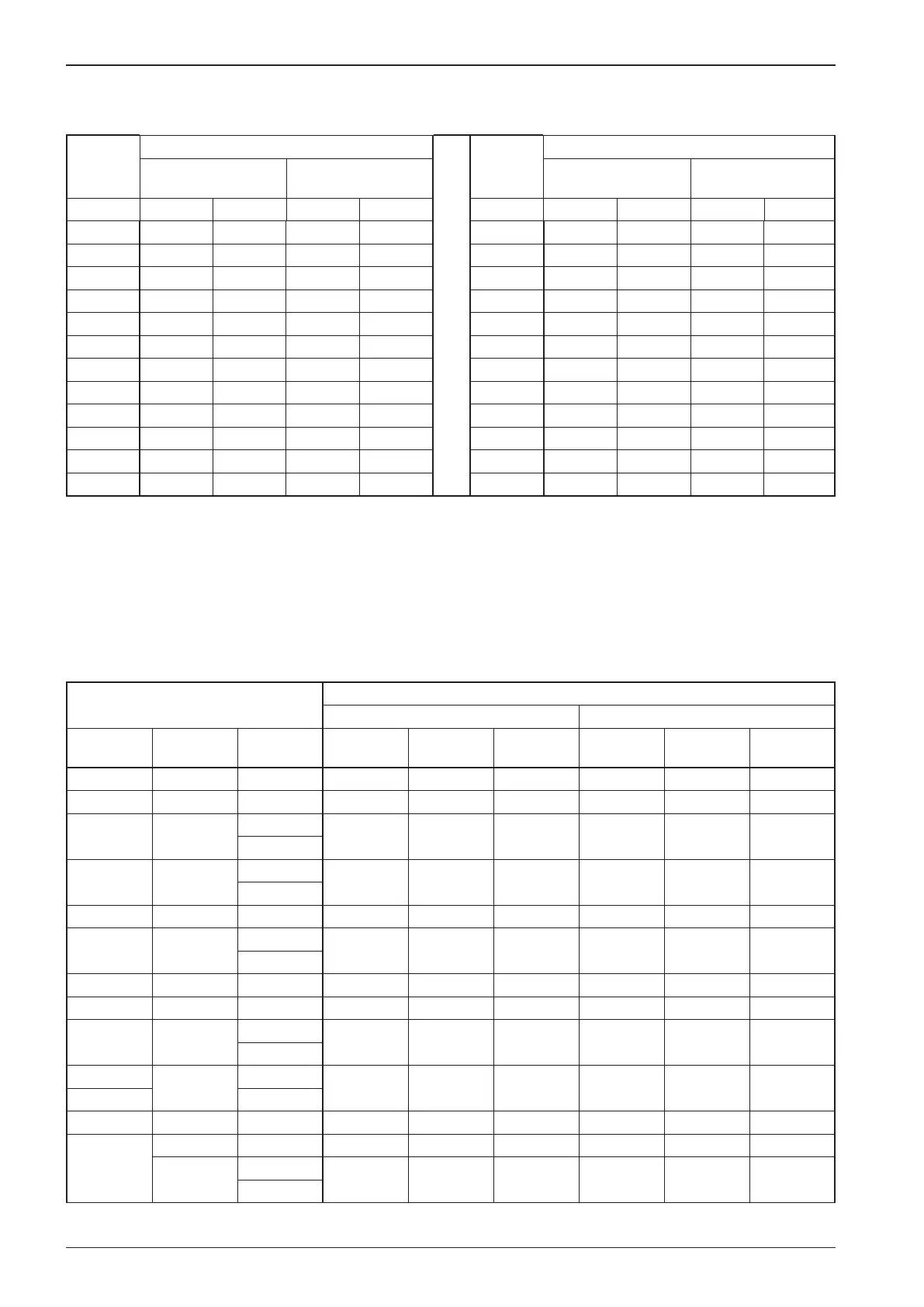

Chart showing the torques for cap nuts with sealing “O” ring – hoses

Tightening moments for the sliding nuts with the tightening circle „O“ - hoses

Nm lb ft

Size

spanner

Worm Hose Nominal Min Max Nominal Min Max

14 12x1,5 6 20 15 25 15 11 18

17 14x1,5 8 38 30 45 28 22 33

19 16x1,5

8

45 38 52 33 28 38

10

22 18x1,5

10

51 43 58 38 32 43

12

24 20x1,5 12 58 50 65 43 37 48

27 22x1,5

14

74 60 88 55 44 65

15

30 24x1,5 16 74 60 88 55 44 65

32 26x1,5 18 105 85 125 77 63 92

36 30x2

20

135 115 155 100 85 114

22

41

36x2

25

166 140 192 122 103 142

46 28

50 42x2 30 240 210 270 177 155 199

50

45x2 35 290 255 325 214 188 240

52x2

38

330 280 380 243 207

280

42

Conrm regularly that no loosening of bolted connections has occurred.

•

Use the torque spanners to do the tightening.

•

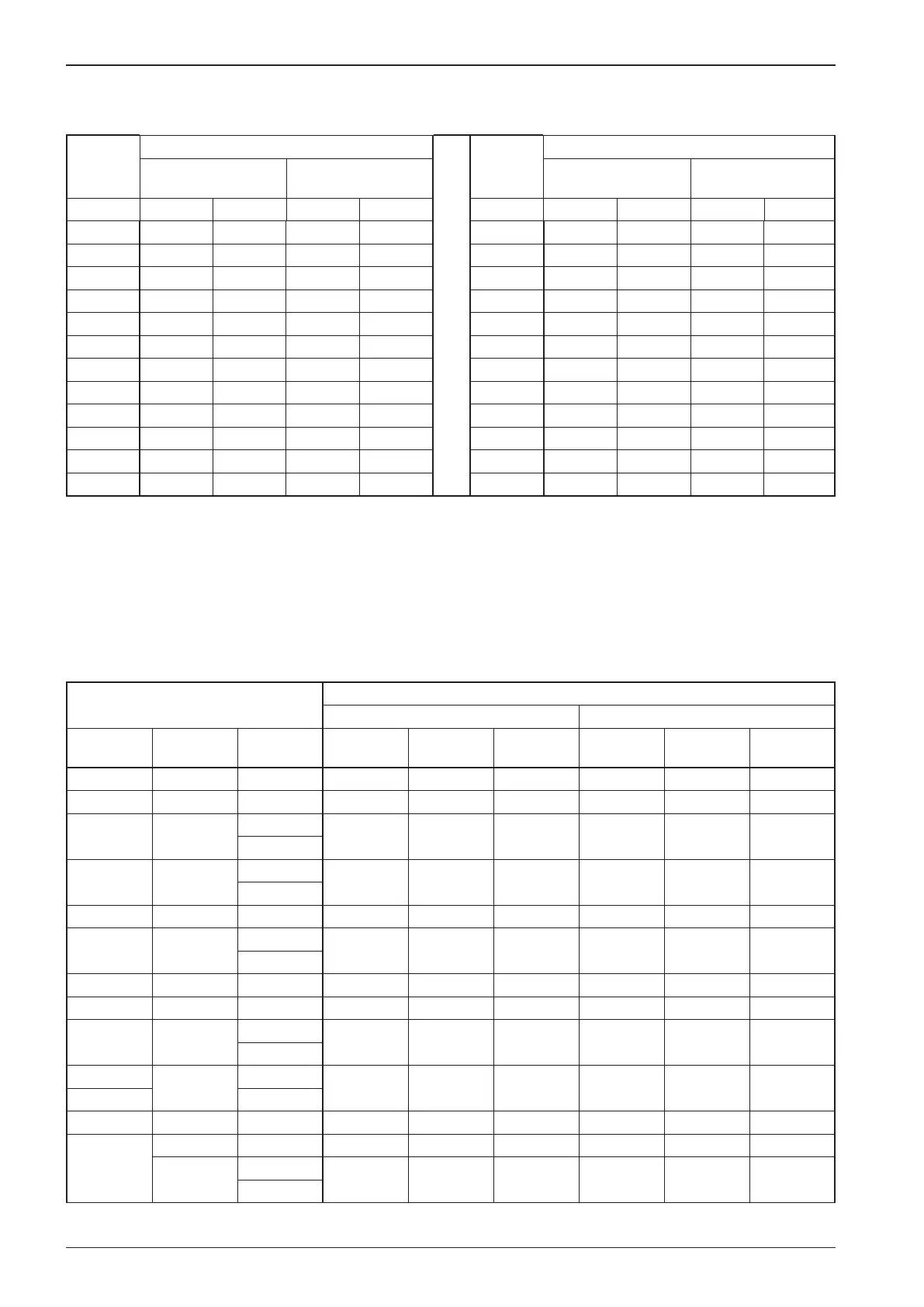

TIGHTENING MOMENT TIGHTENING MOMENT

For the screws

8,8 (8G)

For the screws

10,9 (10K)

For the screws

8,8 (8G)

For the screws

10,9 (10K)

Worm Nm lb-ft Nm lb-ft Worm Nm lb-ft Nm lb-ft

M6 10 7,4 14 10,3 M18x1,5 220 162,2 312 230,1

M8 24 25,0 34 25,0 M20 390 287,6 550 405,6

M8x1 19 14,0 27 19,9 M20x1,5 312 230,1 440 324,5

M10 48 35,4 67 49,4 M22 530 390,9 745 549,4

M10x1,25 38 28,0 54 39,8 M22x1,5 425 313,4 590 435,1

M12 83 61,2 117 86,2 M24 675 497,8 950 700,6

M12x1,25 66 48,7 94 69,3 M24x2 540 398,2 760 560,5

M14 132 97,3 185 136,4 M27 995 733,8 1400 1032,5

M14x1,5 106 78,2 148 109,1 M27x2 795 586,3 1120 826,0

M16 200 147,5 285 210,2 M30 1350 995,7 1900 1401,3

M16x1,5 160 118,0 228 168,1 M30x2 1080 796,5 1520 1121,0

M18 275 202,8 390 287,6

The gures given in the chart are torques at dry thread (with coecient of friction = 0,14). These gures do not apply to a lubricated

thread.

Loading...

Loading...