44 ASC 110

4. Removing the engine

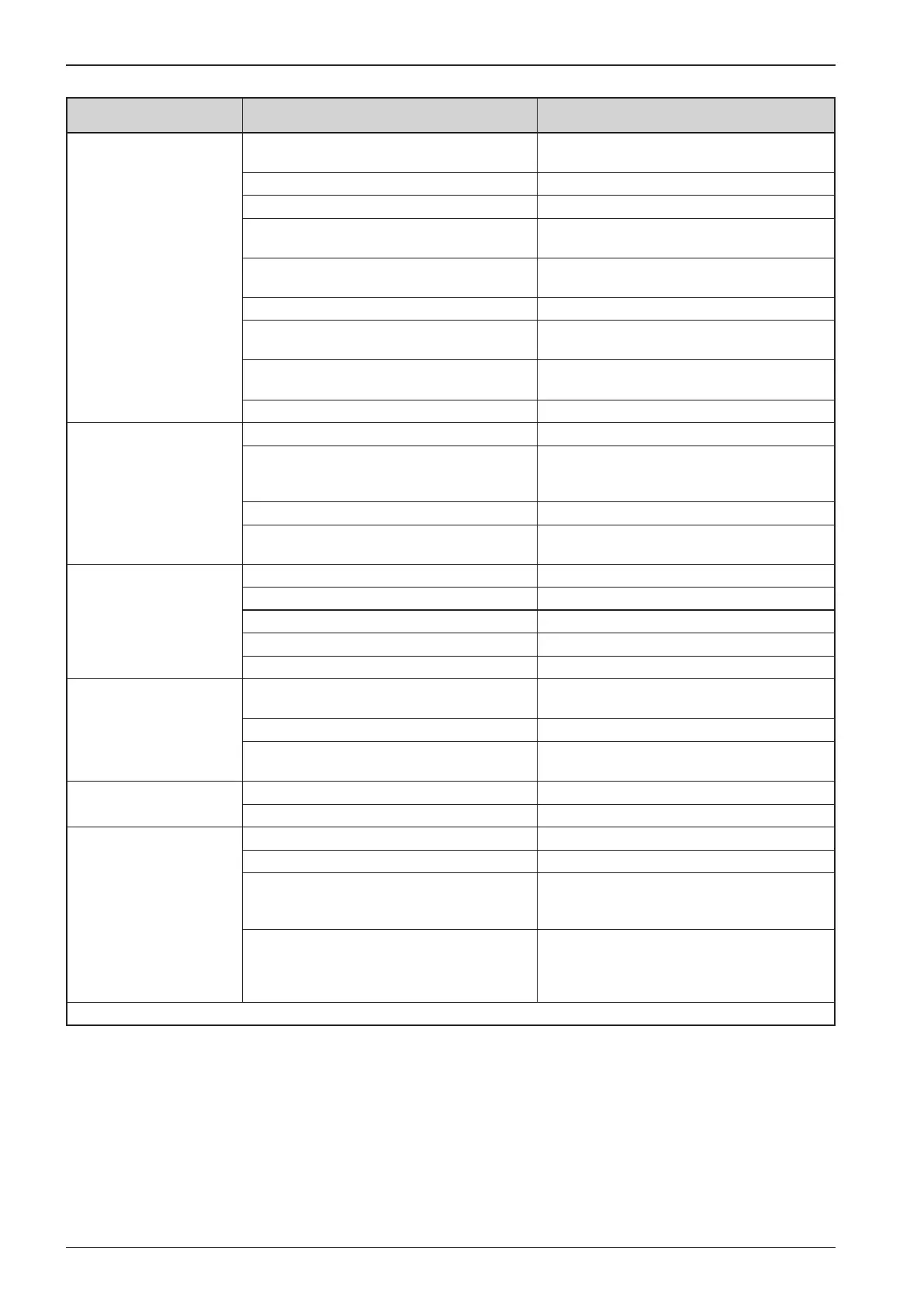

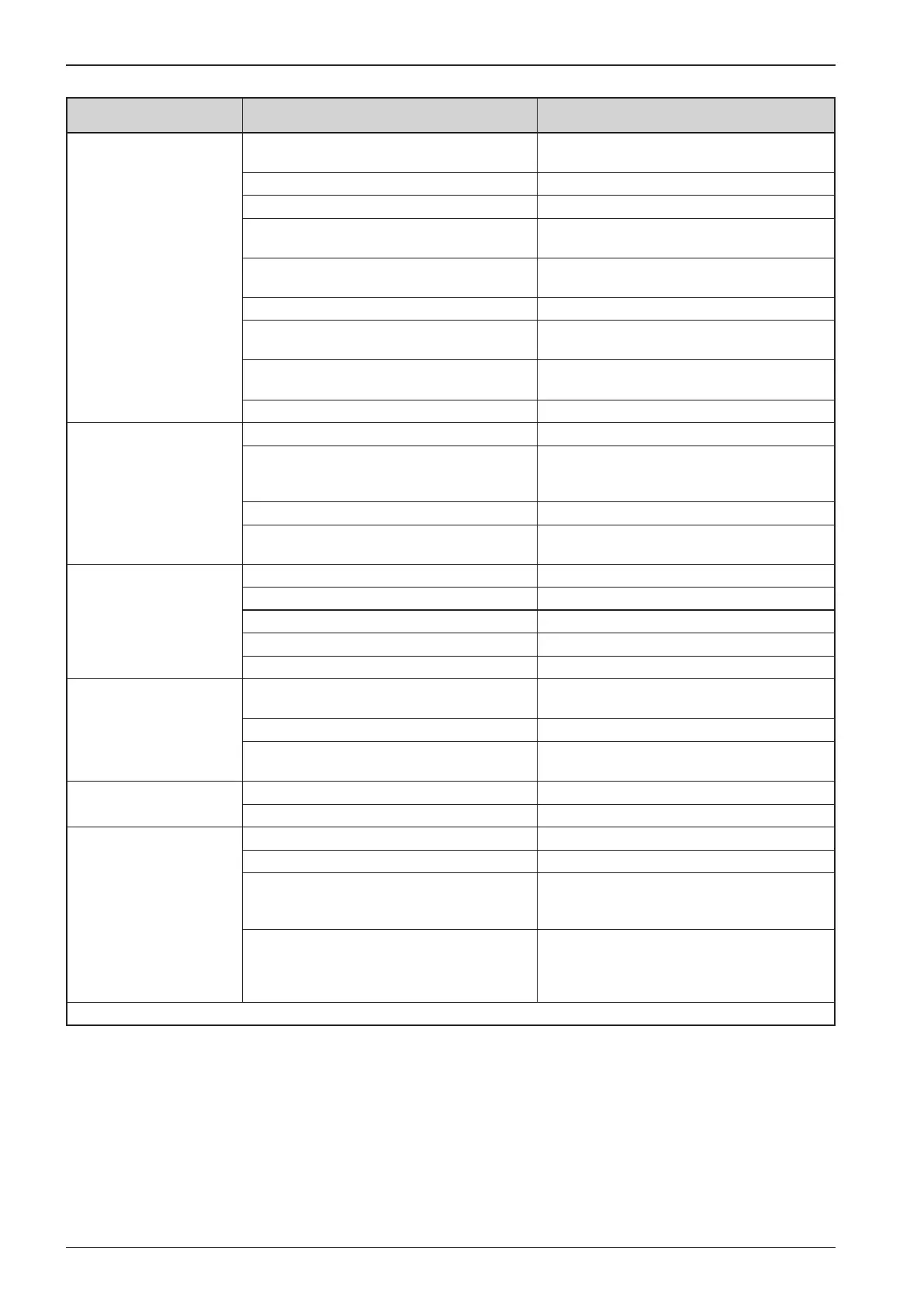

Failure Cause Remedy

The engine is getting

overheated.

Shortage of coolant. Quickly stop the engine, replenish coolant, nd

the untightness and repair it.

Clogged coolant radiator. Clean the radiator.

Failure of the belt tensioning, or broken belt. Repair the failure, replace the belt.

Improperly working thermostat. Verify function of the thermostat; replace if

necessary.

Considerable amount of dirt and sediments in

the cooling circuit.

Clean the cooling circuit.

Faulty injection nozzles. Let expert to check them.

Improperly adjusted fuel volume supplied by

the injection pump.

Let to be adjusted in a specialized workshop.

Ambient temperature too high. Work for a limited time and allow the engine to

cool down.

Improperly adjusted beginning of injection. Let expert to check it.

The engine is not sucient-

ly lubricated - the indicator

of lubrication is on.

Engine oil level too low. Replenish oil.

Engine oil is leaking. Immediately stop the engine, inspect connecti-

ons of the lubrication system and repair the

untightness.

Used oil is of improper viscosity.

Exchange oil for a recommended sort.

Overheated engine. Allow the engine to cool down. Seek for the

reason.

The engine runs irregularly,

with low output

Aerated fuel system. Deareate the fuel system, repair the untightness.

Faulty injection nozzles. Let expert to check it.

Improper valve clearance. Let expert to check it.

Broken injection pipe. Let expert to check it.

Improperly adjusted injection pump. Let expert to check it.

The engine excessively

smokes.

Increased underpressure in the inlet branch of

the engine.

Check function of the underpressure switch.

Replace the lter elements if needed.

Oil level too high. Lower oil level to the upper mark at the dipstick.

Poor compression due to burned or broken

piston rings, or due to wrong valve clearance.

Let the piston rings to be tested in a specia-lized

workshop; adjust the valve clearance.

Excessive oil consumption. Untight oil system. Repair the untightness.

Untight piston rings, or generally worn engine. Let expert to check it.

The engine has not suci-

ent output.

Excessively clogged fuel cleaners. Replace the lter elements.

Wrong valve clearance. Adjust valve clearance.

Clogged holes of the injection nozzles; the

injectors are not adjusted to correct injection

pressure.

Let expert to check it.

Improperly adjusted injection pump. Improperly

adjusted advanced injection angle. The cylinders

have not sucient compression pressure. Failure

of the turbocharger.

Let expert to check it.

Further possible failures are described in the instruction manual of the engine, which is supplied with the machine.

Loading...

Loading...