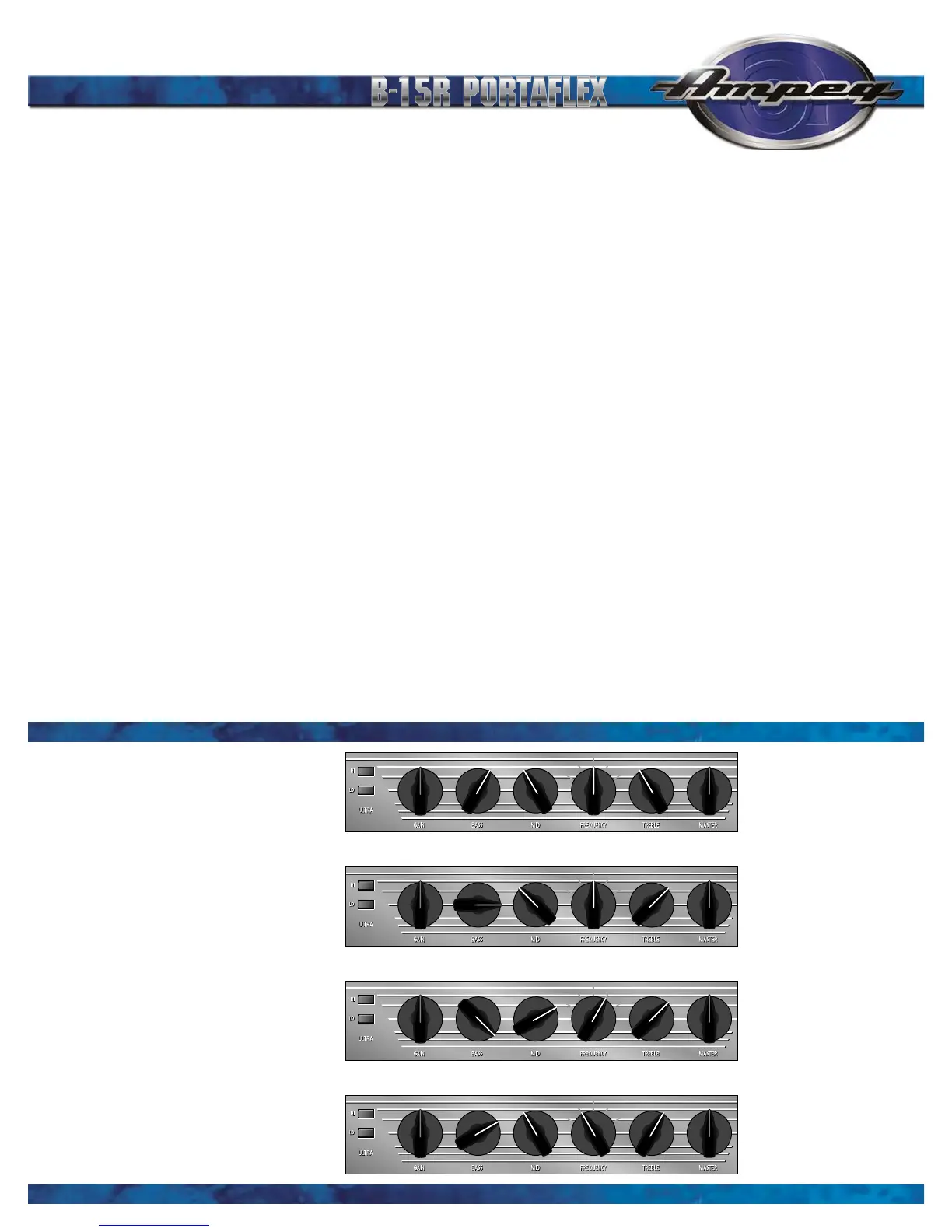

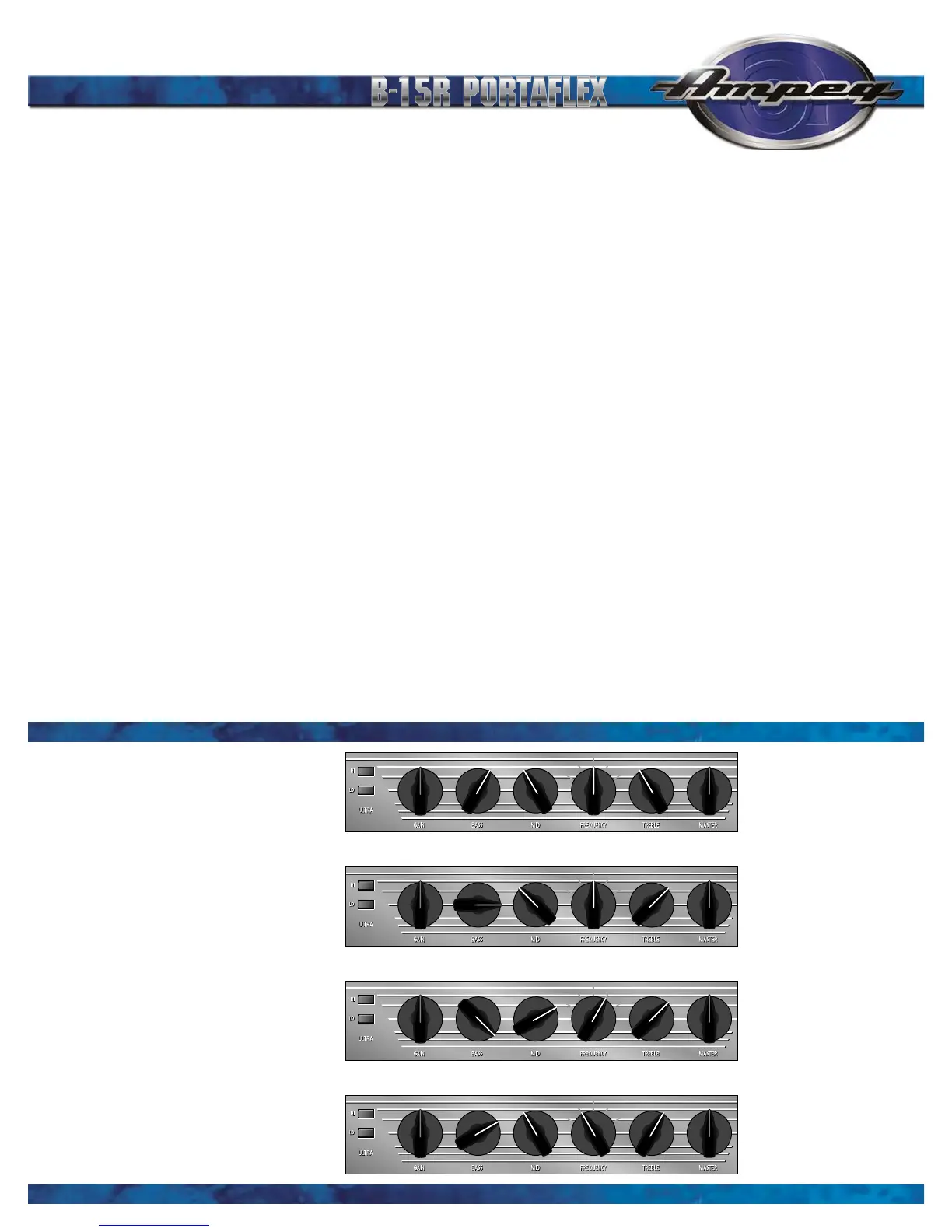

JAZZ:

FUNK:

ROCK:

COUNTRY:

To prolong tube life, observe these tips and recommendations:

• Match the impedance of your speaker cabinet(s) to your amplifier. Improper impedance matching will contribute to early tube degradation and may cause premature tube failure.

• Make sure the speaker(s) are properly connected prior to turning on the amplifier.

• After playing the amplifier, allow sufficient time for it to properly cool down prior to moving it. A properly cooled amplifier prolongs tube life due to the internal components being

less susceptible to the damage caused by vibration.

• Allow the amplifier to warm up to room temperature before turning it on. The heat generated by the tube elements can crack a cold glass housing.

• Replace the output tube(s) before the performance degrades or the tubes fail completely. Replace the tube(s) on a regular basis (at least once per year or as often as every 4

to 6 months if you play long and hard every day).

• Always have the bias checked after replacing the output tubes (unless the amplifier is equipped with "self-biasing circuitry"). This should be done ONLY at a qualified service

center. Improper biasing could result in the tubes running too hot, which greatly reduces the life of the tubes – or too cold, which results in distorted sound regardless of level

settings. Do not play the amplifier if it exhibits these symptoms – get the bias checked/adjusted immediately to prevent tube failure and/or other damage.

• If the locating notch on the base of a power tube breaks off, replace the tube. This significantly reduces the risk of damaging your amplifier by incorrectly inserting the tube.

• Protect the amplifier from dust and moisture. If liquid gets into the amplifier proper, or if the amplifier is dropped or otherwise mechanically abused, have it checked out at an

authorized service center before using it.

• Proper maintenance and cleaning in combination with routine checkups by your authorized service center will insure the best performance and longest life from your amplifier.

CAUTION: Tube replacement should be performed only by qualified service personnel who are familiar

with the dangers of hazardous voltages that are typically present in tube circuitry.

For the best performance and longest tube life, proper biasing is imperative. Bias

is the negative voltage which is applied to the power tube’s control grid to set the

level of idle current. We cannot over emphasize the difference in warmth of tone

and dynamic response that come with proper biasing. If the bias is set too high

(overbiased), the sound from the amp will be distorted at all levels. If the bias is set

too low, (under biased) the power tubes will run hot (the plates inside the tubes may

glow red due to excessive heat) and the sound from the amplifier will lack power

and punch. The excessive heat greatly reduces tube life – from a few days to as

little as a few hours in extreme cases. Setting the bias on your amp is like setting

the idle on your car. If it’s too high or hot it’s running away with you and if it’s too

low or cold it will choke when you step on it.

The bias is adjusted at the factory in accordance with the type of power tube(s)

installed in your amplifier. It is important to point out that tubes of the same type

and specification typically exhibit different performance characteristics.

Consequently, whenever power tubes are replaced, the bias voltage must be

checked (unless the amplifier is equipped with “self-biasing circuitry”) and read-

justed to accommodate the operating parameters of the replacement tubes.

Depending on the model and amplifier type, there may be hum balance controls,

trim pots, or bias adjustment controls on its rear panel. However, the bias adjust-

ment should be performed only by qualified service personnel with the proper, cal-

ibrated test equipment.

SURVIVAL TIPS FOR TUBE AMPLIFIERS:

THE IMPORTANCE OF PROPER BIASING:

SOME SUGGESTED SETTINGS:

Loading...

Loading...