34

8.1 COMPRESSOR OIL HEATING

8 START-UP

CH0305-F05

8.1

1

2

3

4

This operation is not necessary

CHALLENGE -E serie chambers.

Never start a temperature cycle

immediately after start-up.

First heat the compressor oil otherwise

serious damage could be caused.

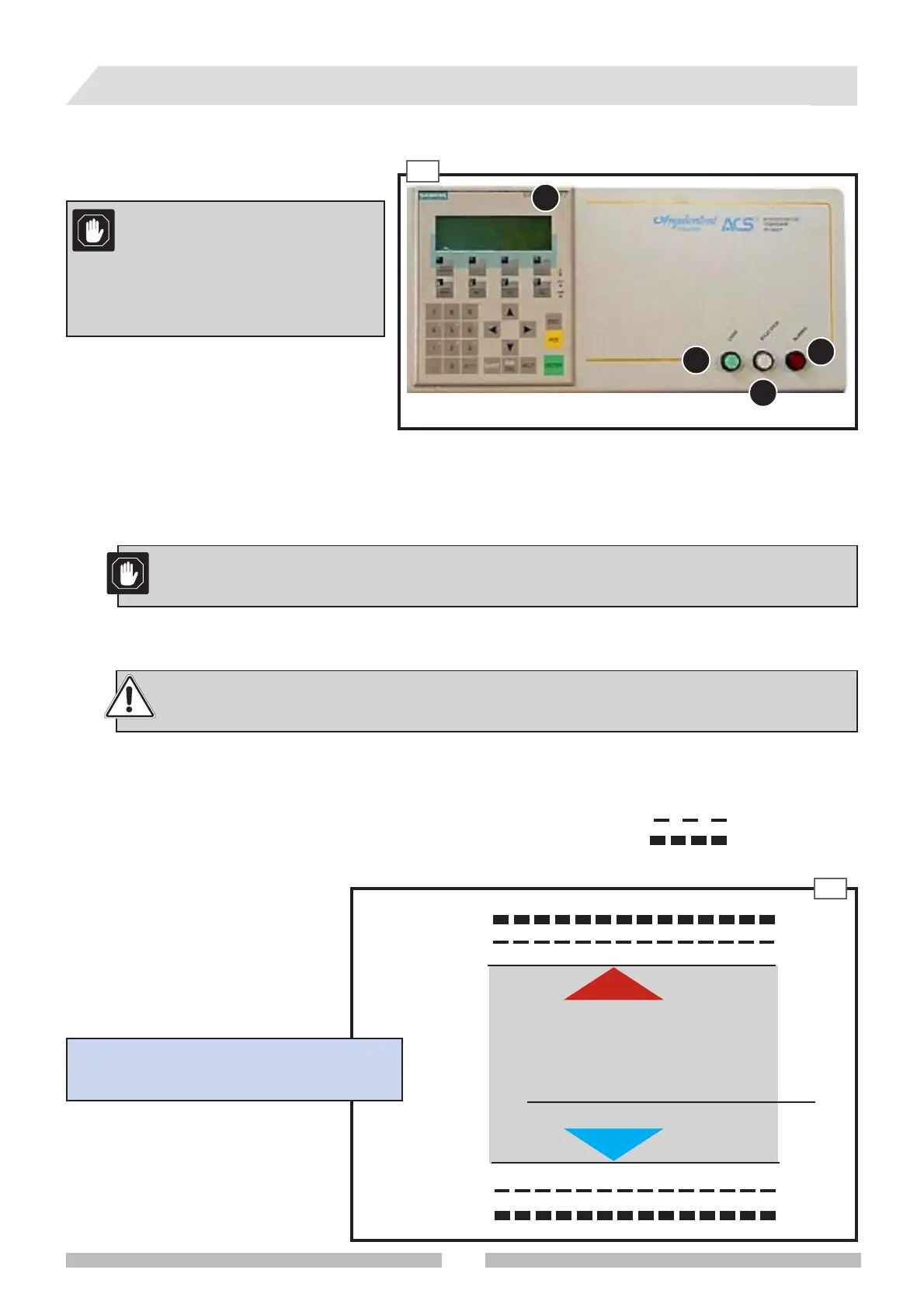

• Turn on the main switch (isolator switch) on

the machine.

• Press the START/STOP button 1 (fig. 8.1).

If the machine has not been operated for over 48 hours:

• Wait 8 hours before starting a temperature cycle.

• The oil heating system will switch off automatically.

If the machine has not been operated for less than

48 hours:

• Wait for about 1-2 hours before starting a temperature

cycle.

• The oil heating system will switch off automatically.

In order to avoid dead time due to compressor oil heating, leave the machine with the main

switch pointing to l (ON) and the START/STOP key pointing to START (lamps lights).

• Check that the mains supply voltage is the same as the one marked on the rating plate.

8.2 ALARM SET-UP

Always set the relevant software and hardware alarm devices before carrying

out a temperature cycle.

Set-up of temperature alarms should be carried out preferable before programming, recalling or carrying out a work

cycle. The machine has three alarm levels:

• Software alarms (paragr. 8.2.1) for maximum and minimum temperature

• Hardware alarms (paragr. 8.2.2) for maximum and minimum temperature

• Fixed alarm for maximum temperature (paragr. 8.2.3)

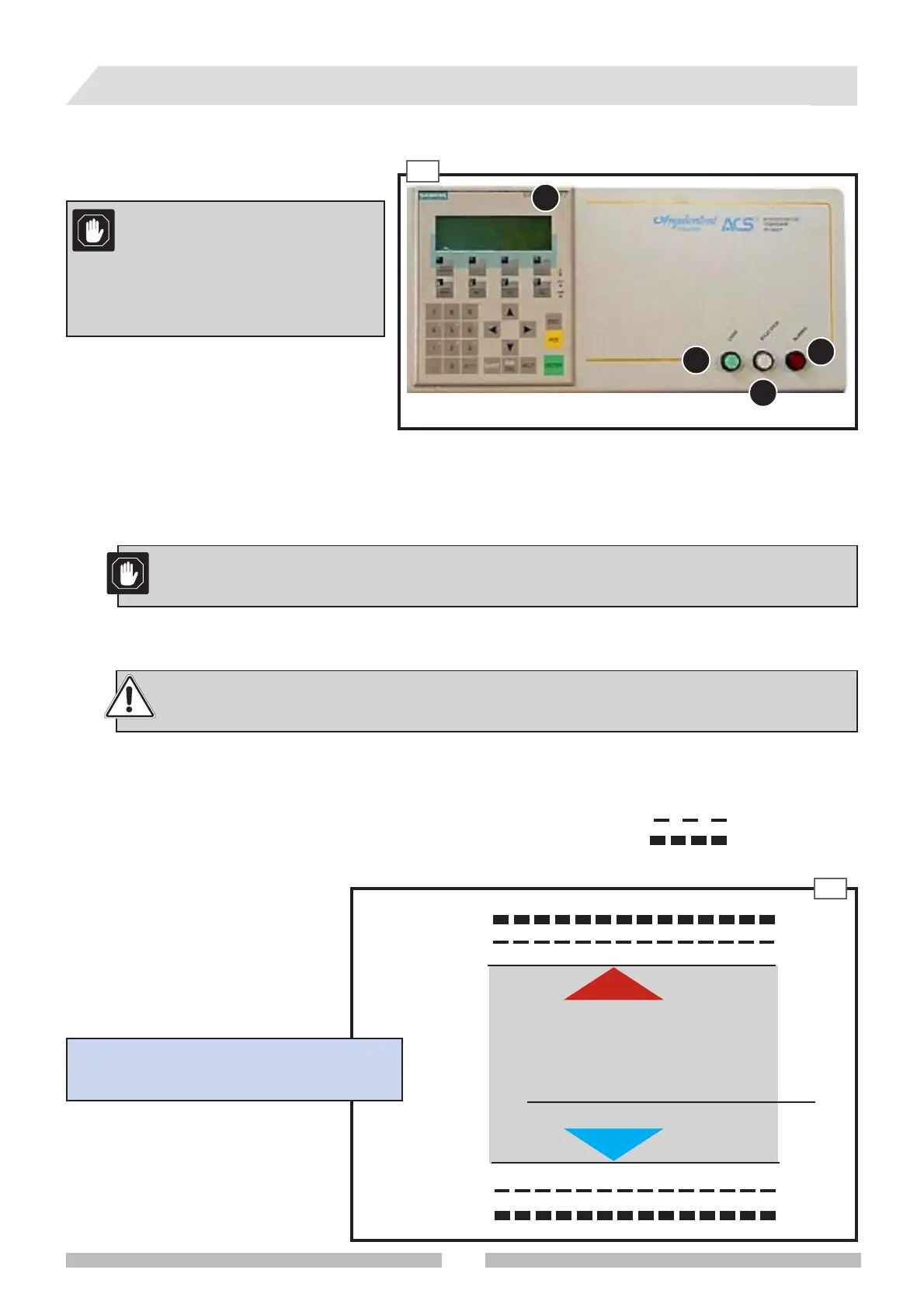

Theoretical diagram of positions of soft-

ware and hardware alarms

maximum temperature software alarm

minimum temperature software alarm

minimum temperature hardware alarm

maximum temperature hardware alarm

WORKING

CYCLE

MIN cycle°C

0°C

MAX cycle °C

8.2

Loading...

Loading...