GB

Form no.: L453147GB– revision 06/2013

5. Installation of pump

5.1 Positioning

Thefollowingmustbeobserved:

Thepumpmustbepositionedsothatthesuctionpipeisasshortas

possibleandthereisaslopinggradienttowardsthesuctionportof

the pump.

Keepthenumberofvalves,bendsandtee-piecesonthesuction

side to an absolute minimum.

Theremustbesufcientspacearoundthepumpforpipingand

accessformaintenance.

5.2 Lining up the pipe system

Ensure that the pipe system is adequately underpinned with pipe

supportssothatthepumpbodyisnotsubjecttostrainfromorthe

weightofthepipesystem.

Caution! Duringthesuctionprocess,thepumpmaytend

tovibrate.Apipesupportshouldbeplacedclose

tothepumpsuctiontopreventpipeworkvibration

creatingexcessivenoise.

5.3 Power supply

Themotormustbeconnectedviaacontrolcabinettothenetworkin

compliancewiththelocalregulations.Moreover,themotormustbe

connectedinaccordancewiththeinstructionsindicatedintheinner

sideoftheconnectingboxlidofthemotor.

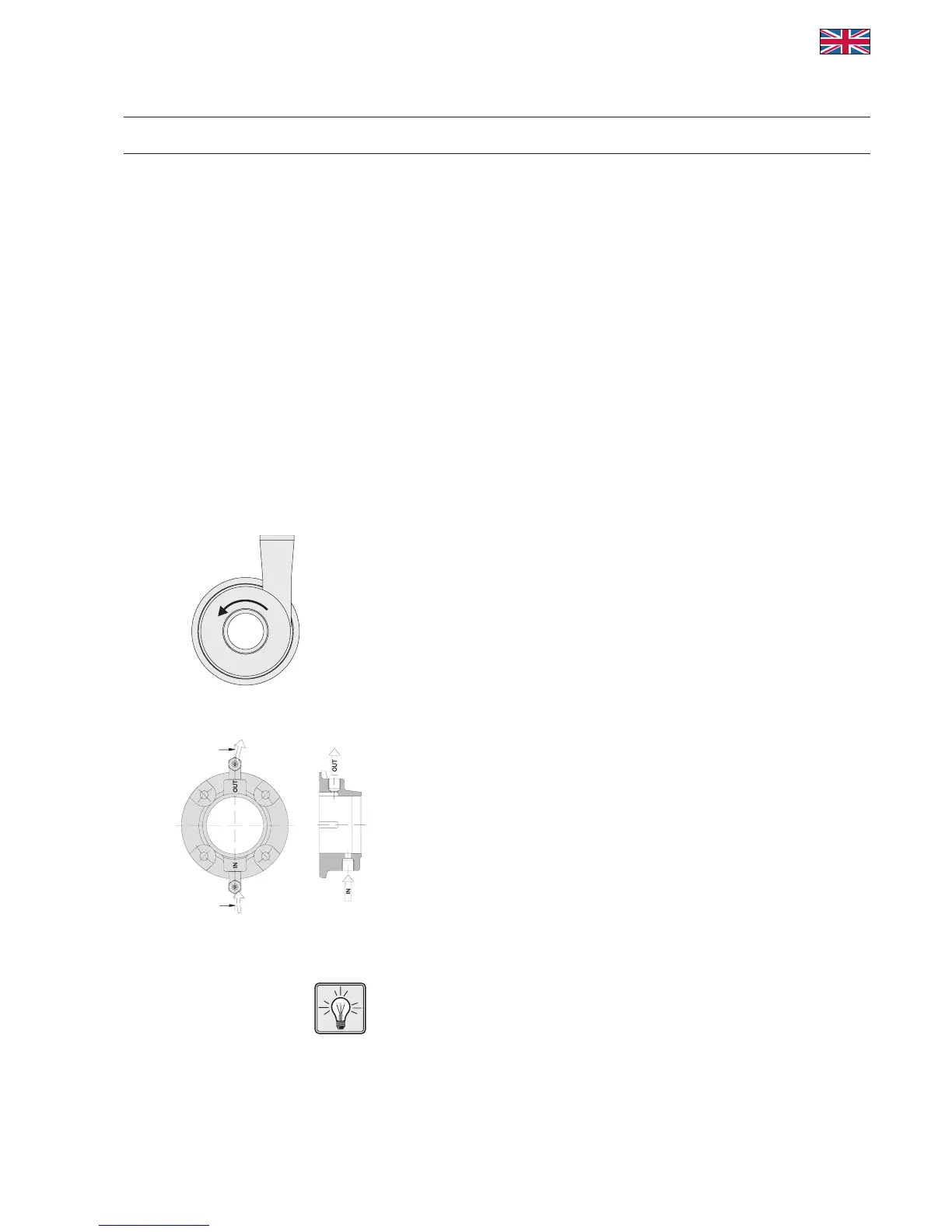

Themotorshouldbeconnectedinsuchawaythatthemotorand

thereforetheimpellerareanti-clockwisewhenviewedfromthefront

inthedirectionofthesuctionportofthepumpbody.(Fig.4).

5.4 Liquid supply for flushed shaft seal

PumpswithaushedshaftsealarettedwithtwoPTFEhose

connectorsonthesealingange.Thehoseconnectorsare1/8inch

andt6.0mmhoses.Therequiredowquantityamountsto15–30l/h.

The maximum permissible pressure is 7 bar.

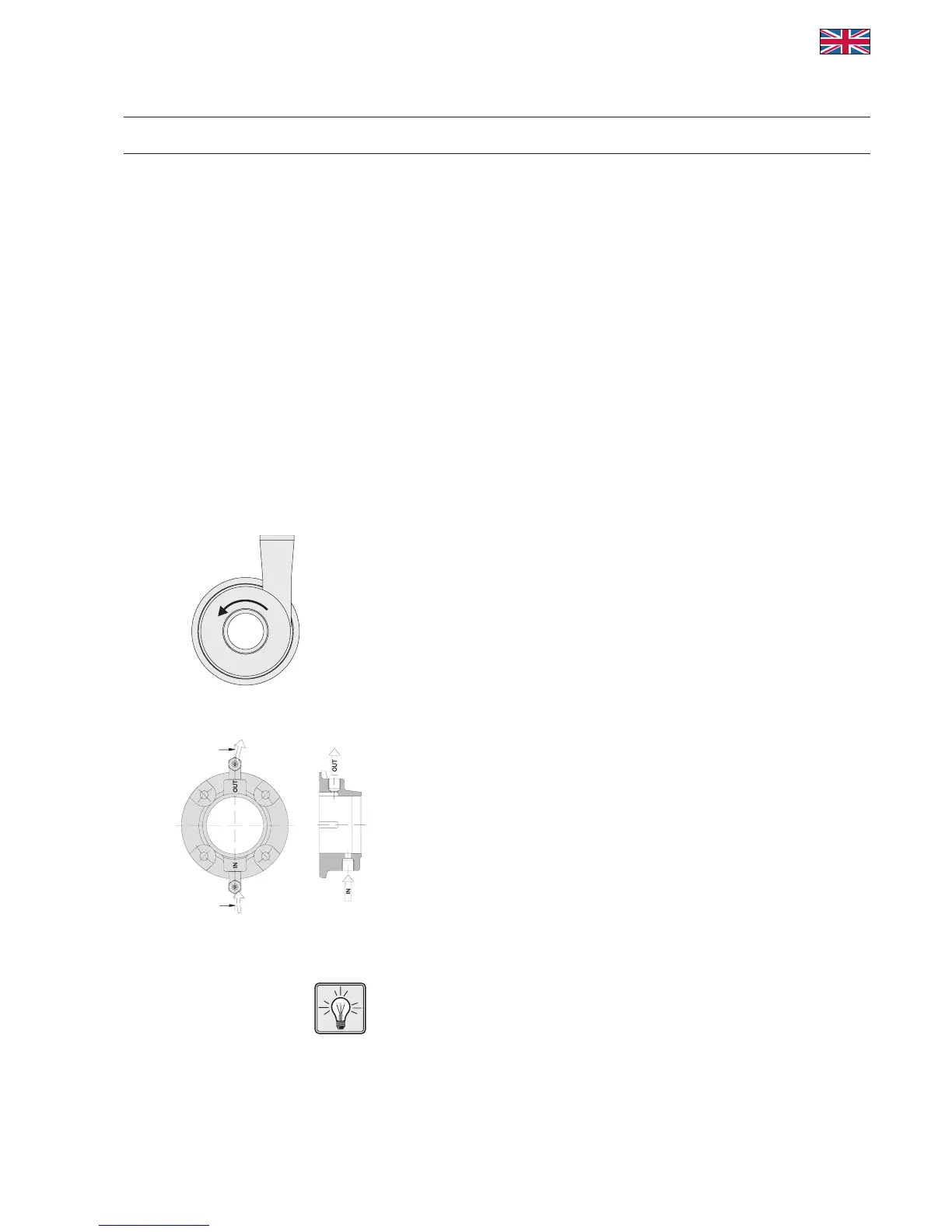

Thehoseconnectionshouldalwaysbepositionedverticallywith

theuidinletbelowandtheoutletabove(Fig.5).

Fluidconsumptioncanbelimitedbyinstallingasolenoidvalveon

thesupplyside.Theopen/closefunctionofthesolenoidvalvecan

becontrolledbythepump'sstart/stopsequence.

Donotusesteamorsteamcondensateontheconnectionfor

ushingliquids.Ifyouwishtousesteamasasealant,aspecial

asepticpipeconnectormustbeused.

Forconnectorssee5.5.

5.5 Connecting steam and steam condensate for aseptic use

Whenstaticdoublesealsareused,theconnectionforsteamor

steamcondensateatthepumpbodyisprovidedwithttingsfor

8 mm stainless steel pipes.

Steamofupto150°Cand5barcanbeused.

Fig. 4

Fig. 5

8

APV

Loading...

Loading...