2

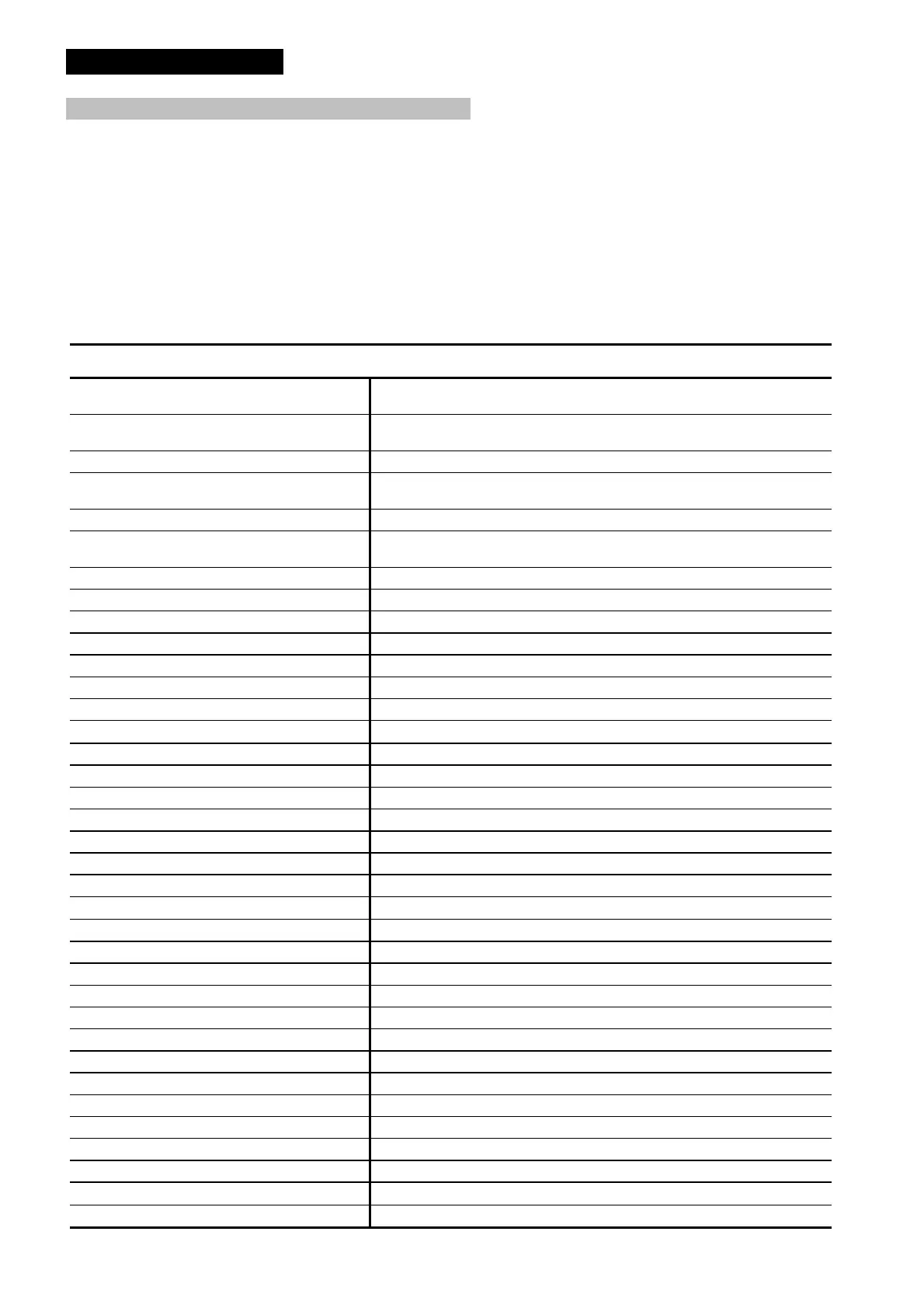

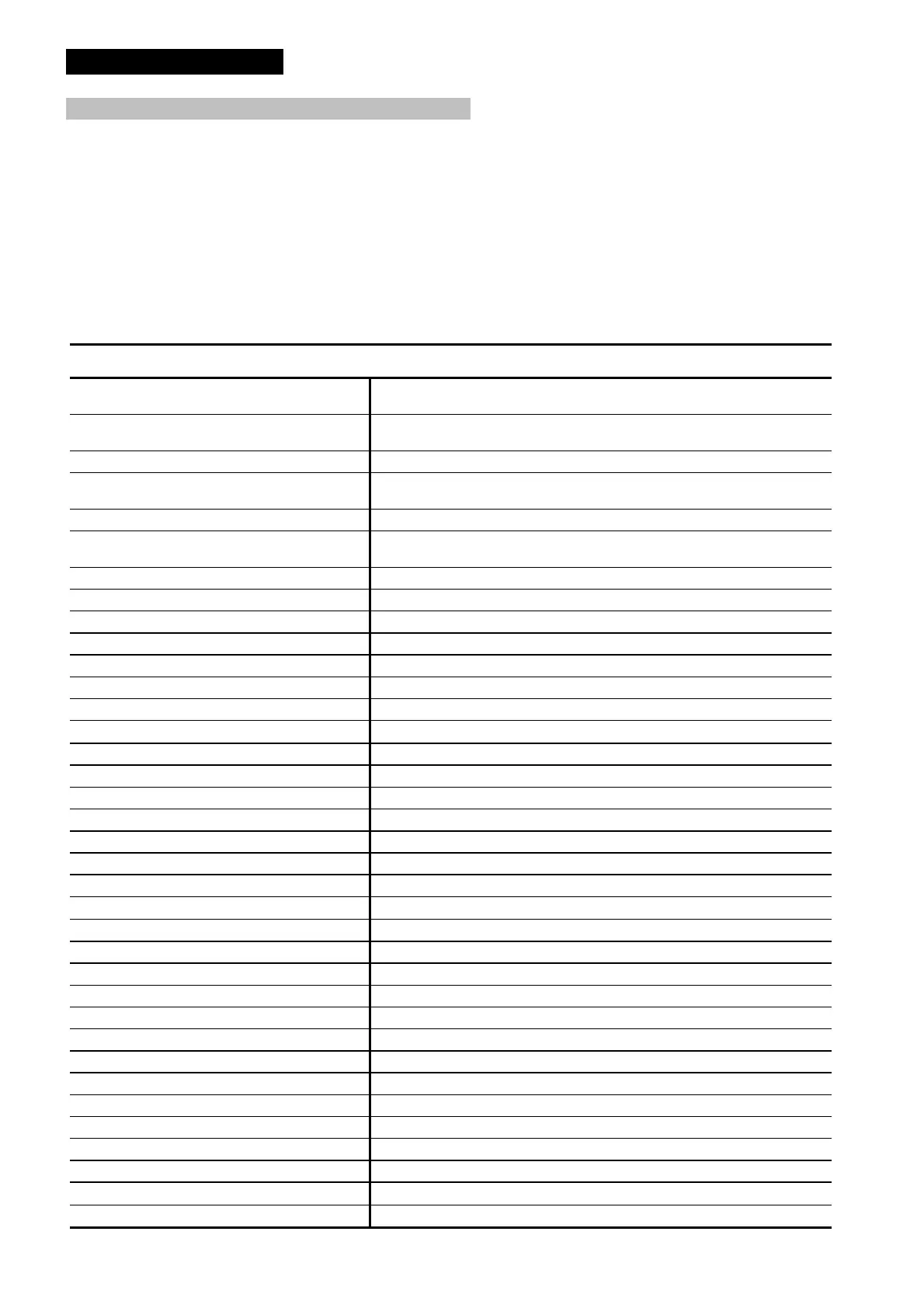

2. TECHNICAL DATA

2.1 MAIN SPECIFICATIONS OF MK BOILERS

− Pressurized steel boiler, for heating systems with hot water production up to 95°C.

− Output: from 44 to 269 kW. - Running: light oil-gas.

− Cylindrical furnace, flame inversion, detached from the back duct plate, arc-welded on a copper bar.

− Steel boiler body Fe360 UNI EN 10025/92, completely electro-welded in a CO

2

controlled atmosphere

.

− Steel duct bundle Fe360D UNI EN 10204/2.2, 4 mm thickness.

− Completely adjustable door allowing perfect combustion product tightness.

− Epoxy enamelled boiler jacket, 80 mm thick glass fibre insulation pad to reduce passive heat leakages.

− The switchboard is outside the jacket and is fitted with an operating thermostat, a manual reset safety thermostat, a thermometer, a

minimal temperature thermostat on the circulating pump, an anti-inertia thermostat, a general switch, a circulating pump switch and

burner switch. Rubber sheath with IP 40 minimal protection level.

MK 55 MK 70 MK 80 MK 90 MK 100

kW

kcal/h

44 ÷ 54,7

37.840 ÷ 47.042

50 ÷ 68,4

43.000 ÷ 58.824

62 ÷ 80,1

53.320 ÷ 68.846

75 ÷ 90,3

64.500 ÷ 77.658

90 ÷ 100,1

77.400 ÷ 86.086

kW

kcal/h

48 ÷ 60,2

41.280 ÷ 51.772

54 ÷ 74,7

46.440 ÷ 64.242

67 ÷ 87,4

57.620 ÷ 75.164

80,5 ÷ 98,8

69.230 ÷ 84.968

97 ÷ 109,3

83.420 ÷ 93.998

Combustion chamber volume m³ 0,056 0,056 0,056 0,100 0,100

kW/m³

kcal/h m

3

1.075

924.500

1.334

1.147.179

1.561

1.342.214

988

849.680

1.093

939.980

Exchange surface m² 2,7 2,7 2,7 4,3 4,3

kW/m²

kcal/h m²

20,3

17.423

25,3

21.787

29,7

25.513

21,0

18.060

23,3

20.020

Smoke duct number n° 18 18 18 23 23

Smoke duct diameter Ø est. 1½” 1½” 1½” 1½” 1½”

Boiler weight kg 200 220 220 300 310

Water content l 90 90 90 140 140

Operating pressure bar 5 5 5 5 5

Hydraulic pressure bar 7,5 7,5 7,5 7,5 7,5

Max. operating temperature °C 95 95 95 95 95

Water loss of heat ∆t=15°C mbar

8 10 13 12 14

Combustion chamber pressure mbar 0,12 0,15 0,2 0,24 0,36

Min. efficiency at 100% % 87,5 87,7 87,8 87,9 88

Efficiency at 100% % 90,7 91,5 91,5 91,3 91,5

Min. efficiency at 30% % 85,3 85,5 85,8 85,9 86,1

Efficiency at 30% % 88,5 88,9 89 89,3 90,1

Loss of heat at the chimney with operating burner % 8,2 7,48 7,45 7,61 7,35

Loss of heat at the chimney with burner out % 0,28 0,3 0,26 0,32 0,26

Jacket losses ∆t=50°C %

1,1 1,02 1,05 1,09 1,15

Burner connection (Ø) mm 125 125 125 150 150

Flue connection (Ø) mm 200 200 200 200 200

Min. chimney depression mbar 0,2 0,2 0,2 0,2 0,2

Max. smoke temperature °C 180 185 188 181 185

Smoke temperature in output range °C 141 ÷ 180 148 ÷ 185 151 ÷ 188 146 ÷ 181 155 ÷ 185

CO

2

a gas % 9,8 9,7 10 9,6 9,75

CO a gas ppm 27 24 22 25 19

NOx a gas ppm 43 39 42 45 40

Max. light oil smoke flow rate m³/h 150 180 210 240 270

Max. methane smoke flow rate m³/h 133 159 185 212 239

Light oil burning air volume (practice) m³/h 82 98 114 131 148

Methane burning air volume (practice) m³/h 76 90 105 120 136

Combustion chamber dimension (DiameterXLenght) mm

330 × 650 330 × 650 330 × 650 390 × 830 390 × 830

Thermostat adjustment range °C 55 ÷ 80 55 ÷ 80 55 ÷ 80 55 ÷ 80 55 ÷ 80

Output

Fornace output

Thermal load

Thermal output

Loading...

Loading...