5

2.3 TECHNICAL SPECIFICATIONS OF PRK BOILERS

− Steel boiler with pressurized combustion, for heating and hot water systems up to 95° C.

− Output: from 260 up to 3500 kW.

− Running : light oil and gas.

− Cylindrical furnace with flame inversion, detached from the back duct plate, arc-welded on a copper bar.

− Steel boiler body Fe 360 UNI EN 10025/92, completely electro-welded in a CO2 controlled atmosphere.

− Steel duct bundle Fe 360D UNI EN 10204/2.2, 4 mm thickness.

− Dispenser of the return water returning from the system towards the front duct plate allowing a better cooling and limiting carbonate and

magnesium deposits.

− Completely adjustable door allowing perfect combustion product tightness.

− Epoxy enamelled steel jacket with, and boiler body insulation by means of 80 mm thick glass fibre pad.

− The switchboard is outside the jacket and fitted with a manual reset thermostat, a thermometer, a minimal temperature thermostat, an

anti-inertia thermostat, a general switch, a circulating pump switch and a burner switch. Rubber sheath with IP40 minimal protection

level.

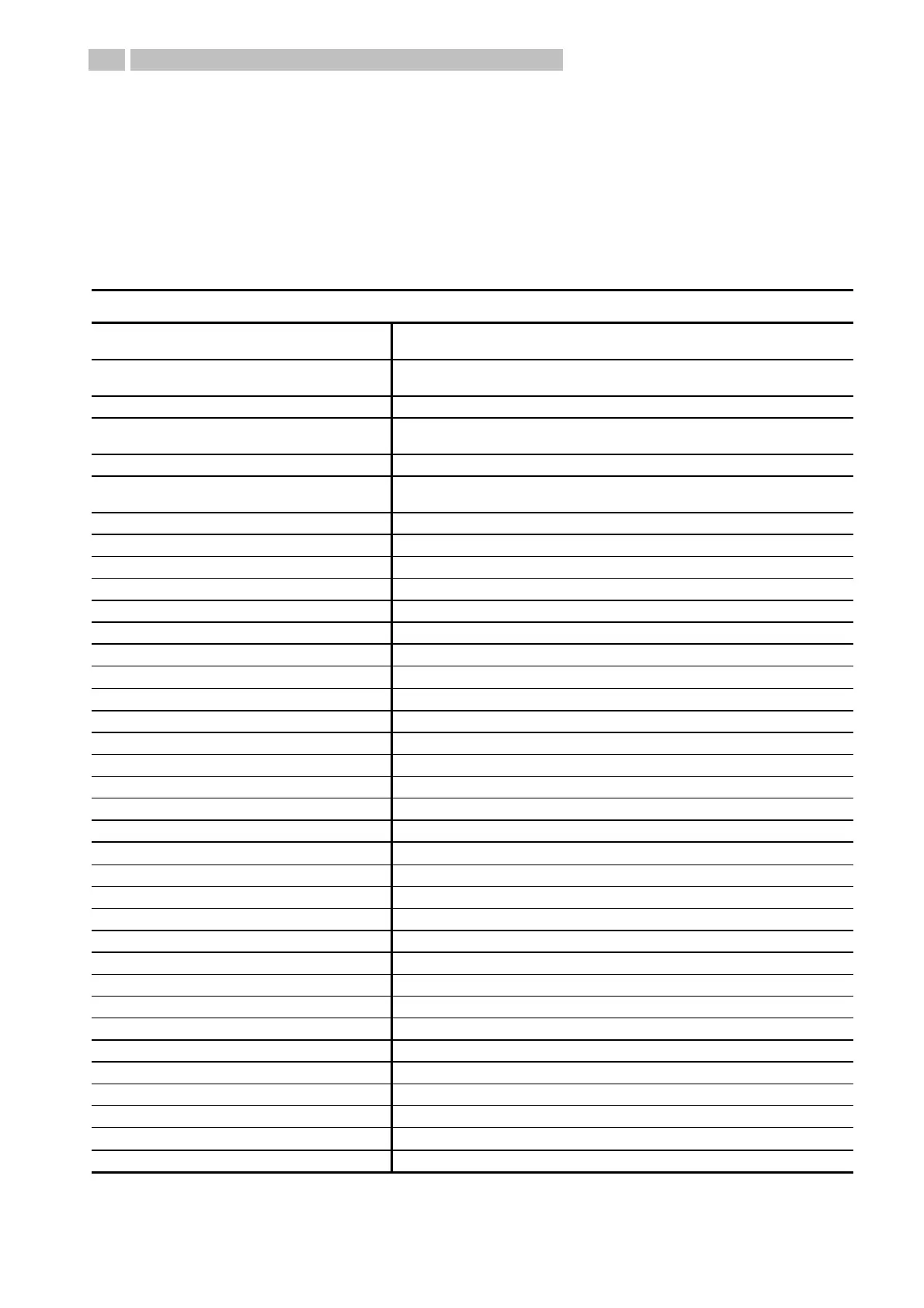

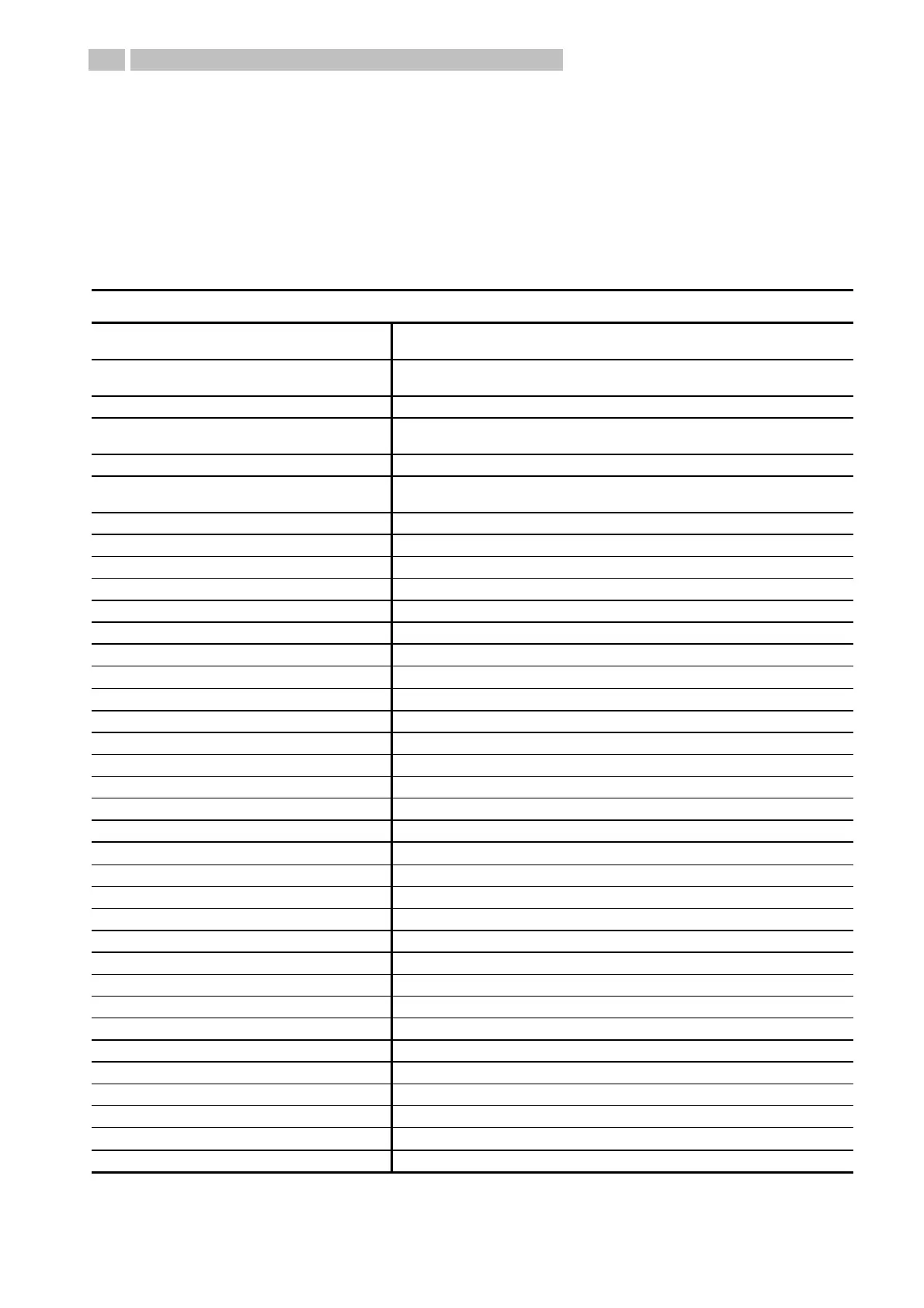

PRK 350 PRK 420 PRK 470 PRK 520 PRK 600

kW

kcal/h x 1000

260 ÷ 349

223,6 ÷ 300,14

300 ÷ 419

258 ÷ 360,34

380 ÷ 470

326,8 ÷ 404,2

400 ÷ 524

344 ÷ 450,64

470 ÷ 600

404,2 ÷ 516

kW

kcal/h x 1000

281 ÷ 379

241,6 ÷ 325,94

324 ÷ 457,8

278,6 ÷ 393,7

410 ÷ 510,5

352,6 ÷ 439,03

430 ÷ 571

369,8 ÷ 491,06

506 ÷ 654

435,1 ÷ 562,4

Combustion chamber volume m³ 0,293 0,293 0,39 0,39 0,467

kW/m³

kcal/h m³

1.293,5

1.112.410

1.562,4

1.343.664

1.308,9

1.125.654

1.464

1.259.040

1.400,4

1.204.344

Exchange surface m² 8,3 9,3 9,7 9,7 12

kW/m²

kcal/h m²

42

36.120

45

38.700

48,5

41.710

54

46.440

50

43.000

Smoke duct number n° 28 30 33 33 33

Smoke duct diameter Ø est. 1½” 1½” 1½” 1½” 1½”

Boiler weight kg 650 740 1.070 1.070 1.250

Water content lt. 340 400 470 470 570

Operating pressure bar 6 6 6 6 6

Hydraulic pressure bar 9 9 9 9 9

Max. operatine temperature °C 95 95 95 95 95

Water loss of heat ∆t=15°C mbar

24 38 19 23 32

Combustion chamber pressure mbar 2,4 3,6 3,8 4,1 4,8

Minimum efficiency at 100% % 89 89,2 89,2 89,2 89,2

Efficiency at 100% % 90,2 91,5 92 91,7 91,7

Minimum effciency at 30% % 87,6 87,8 87,8 87,8 87,8

Efficiency at 30% % 91,3 92,8 93,4 93 93

Loss of heat at the chimney with working burner % 7,38 7,8 7,45 7,65 7,65

Loss of heat at the chimney with burner out % 0,25 0,24 0,2 0,22 0,22

Loss of heat at the jacket ∆t=50°C %

0,62 0,7 0,55 0,65 0,65

Burner connection (Ø) mm 210 210 240 240 240

Flue connection (Ø) mm 250 250 300 300 300

Min. chimney depression mbar 0,2 0,2 0,2 0,2 0,2

Max smoke temperature °C 190 188 180 185 190

Smoke temperature in the output range °C 151 ÷ 190 147 ÷ 188 148 ÷ 180 151 ÷ 185 151 ÷ 190

CO

2

a gas % 9,8 9,7 10 9,9 9,9

CO a gas ppm 6 15 28 19 19

NOx a gas ppm 56 48 61 52 52

Max. light oil smoke flow rate m³/h 894 1.080 1.205 1.344 1.595

Max. methane smoke flow rate m³/h 790 967 1.064 1.200 1.447

Light oil burning air volume (practice) m³/h 489 590 658 735 842

Methane burning air volume (practice) m³/h 450 544 616 684 749

Combustion chamber dimensions (DiameterxLenght) mm

530 × 1.300 530 × 1.300 628 × 1.250 628 × 1.250 628 × 1.500

Thermostat adjustment range °C 55 ÷ 80 55 ÷ 80 55 ÷ 80 55 ÷ 80 55 ÷ 80

Output

Fornace output

Thermal load

Thermal output

Loading...

Loading...