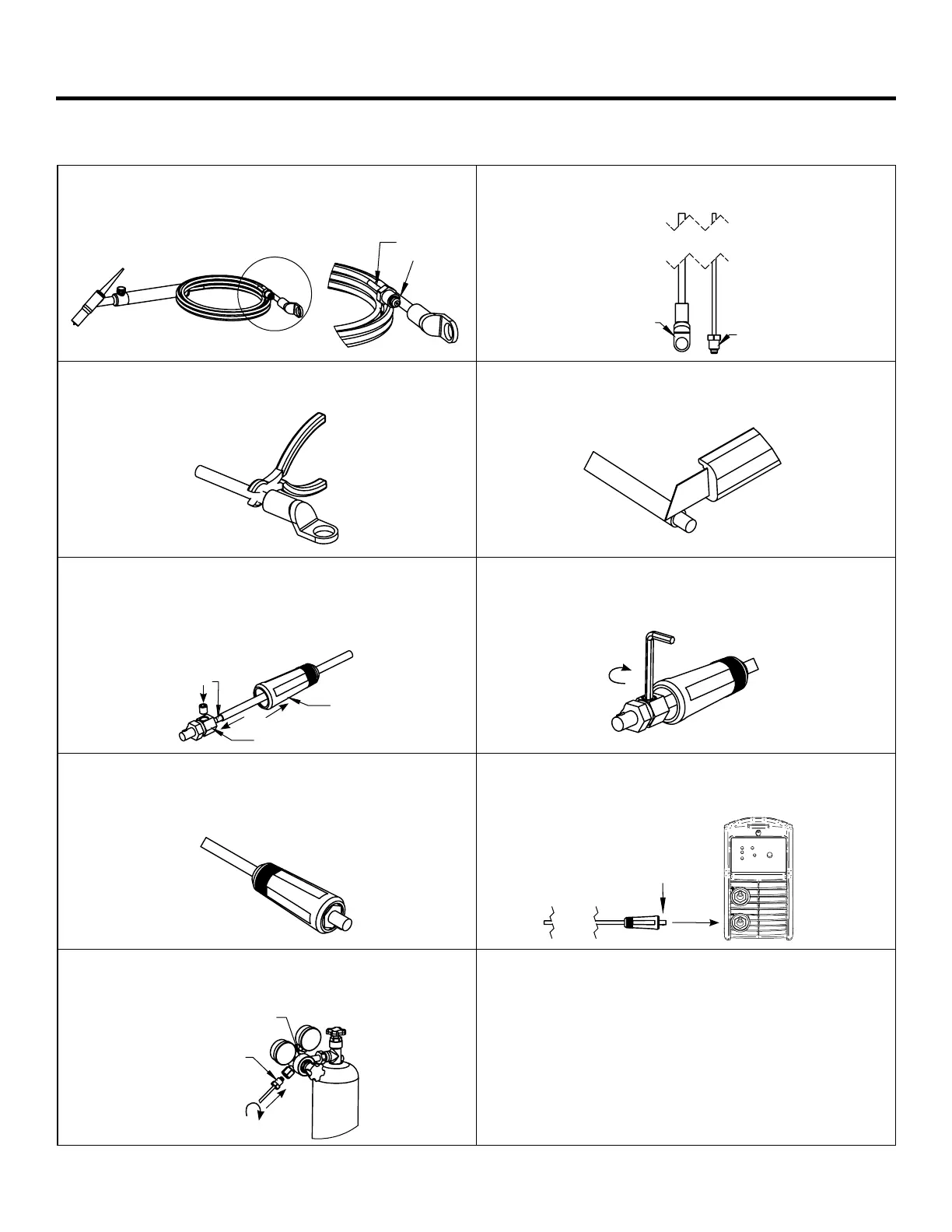

TIG TORCH K1782-7 INSTALLATION

F-1 F-1

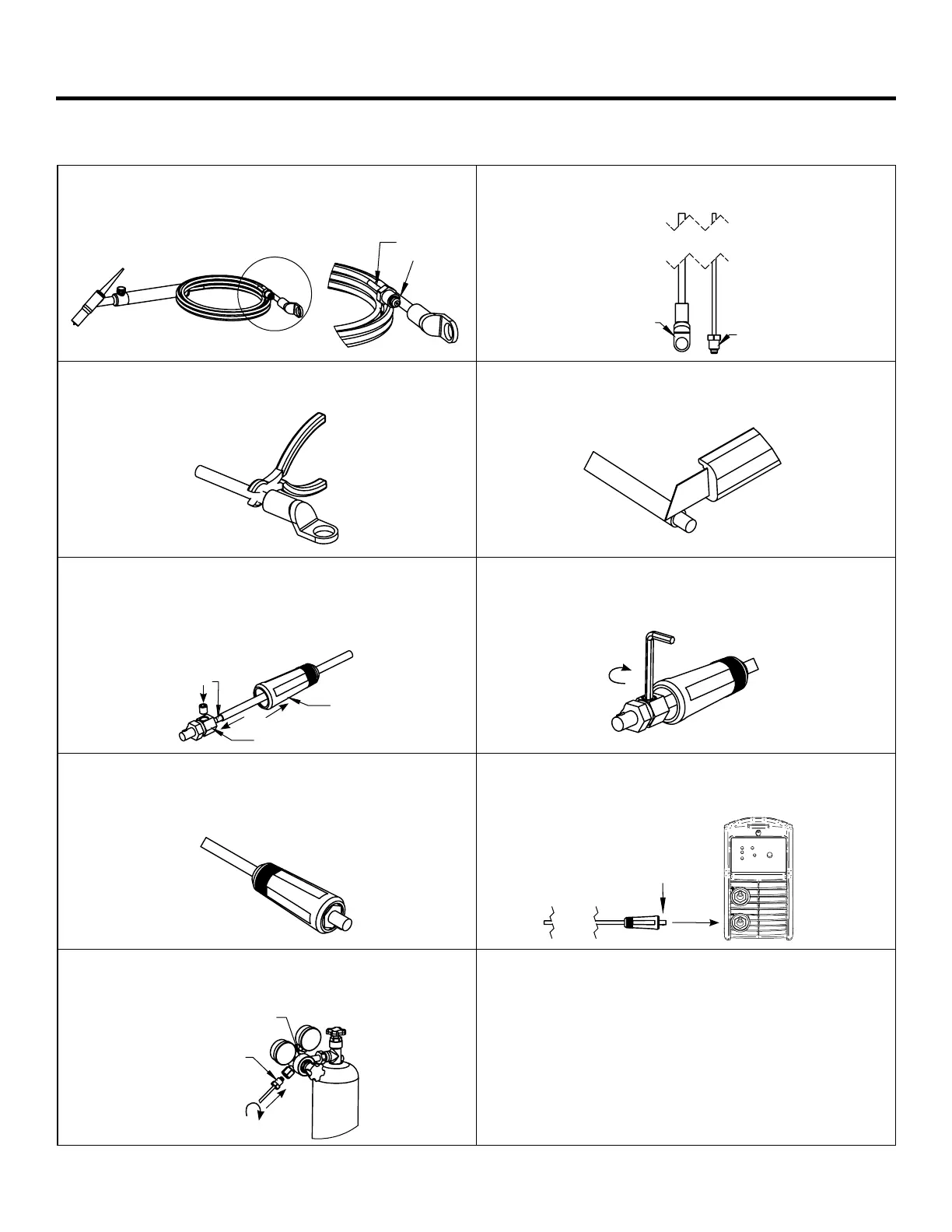

STEP 1:

Identify that the torch K1782-7 have two lines, gas line

and work wire.

STEP 2:

Identify torch tips, lug and pigtel.

STEP 3:

Cut the lug of the power cable.

STEP 4:

Cut the insulation aprox 1/2 inch.

STEP 5:

Place the plastic body of the quick connector into the

power cable, then place the brass quick connector to

the uncovered cable part ( copper), make sure it ts

securely with copper.

STEP 6:

With the Allen wrench rmly tighten the set screw bronze

connector.

STEP 7:

Place the plastic body brass connector, be careful to

align well plastic entries to the brass connector.

STEP 8:

When the cover is fully seated, connect it to the negative

input of the machine.

STEP 9:

Connect the torch pigtel to the regulator with ow meter

and tighten it securely.

STEP 10:

Place the work wire, energize the machine,

open and bleed the gas, put in TIG position,

adjust parameters and welding.

A

Gas line

Work wire

Lug

Pigtel

Plastic body

Quick connector

Uncovered cable

Tight

Connect to the negative input (-)

Flow meter

Pigtel

Tight

Loading...

Loading...