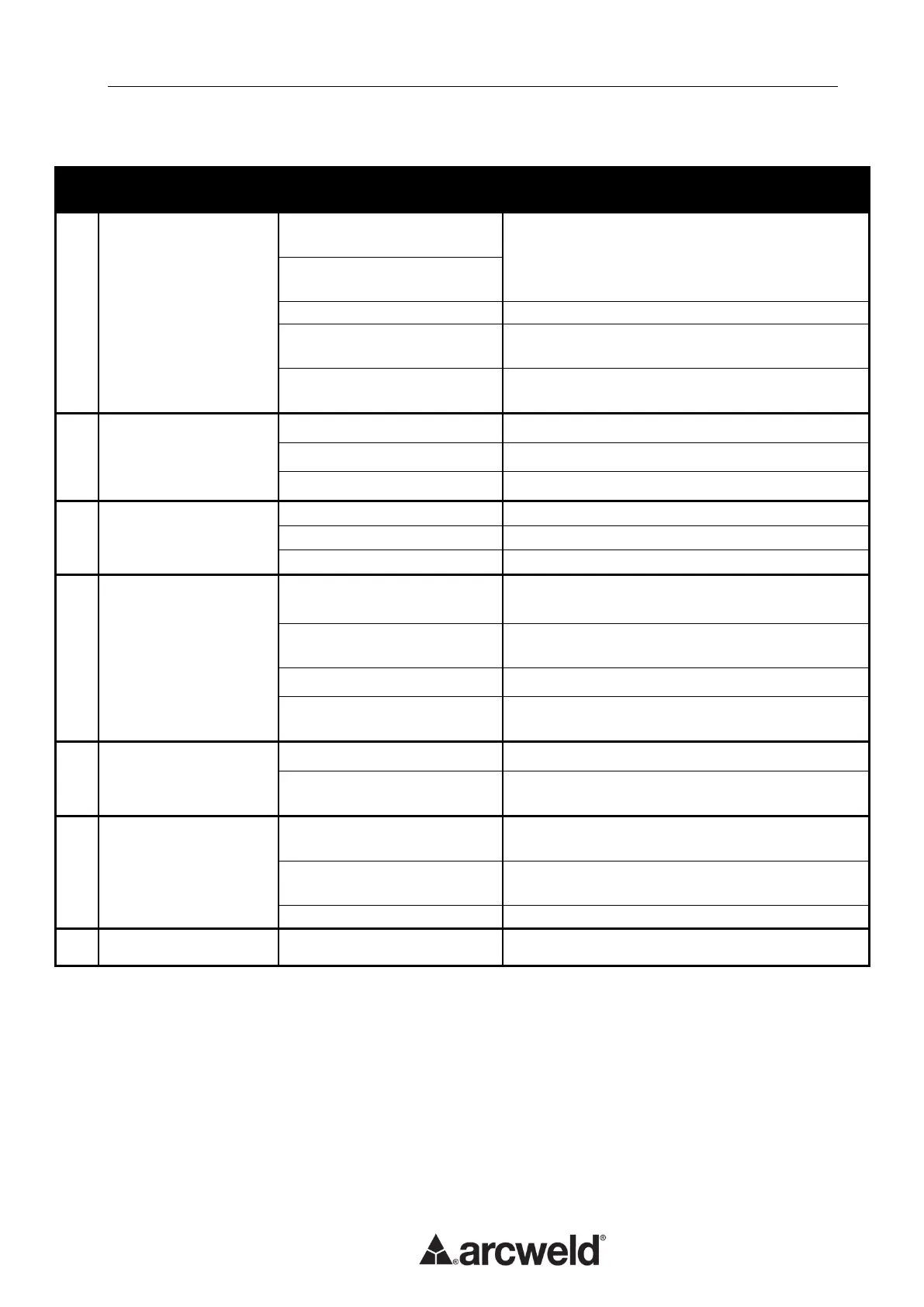

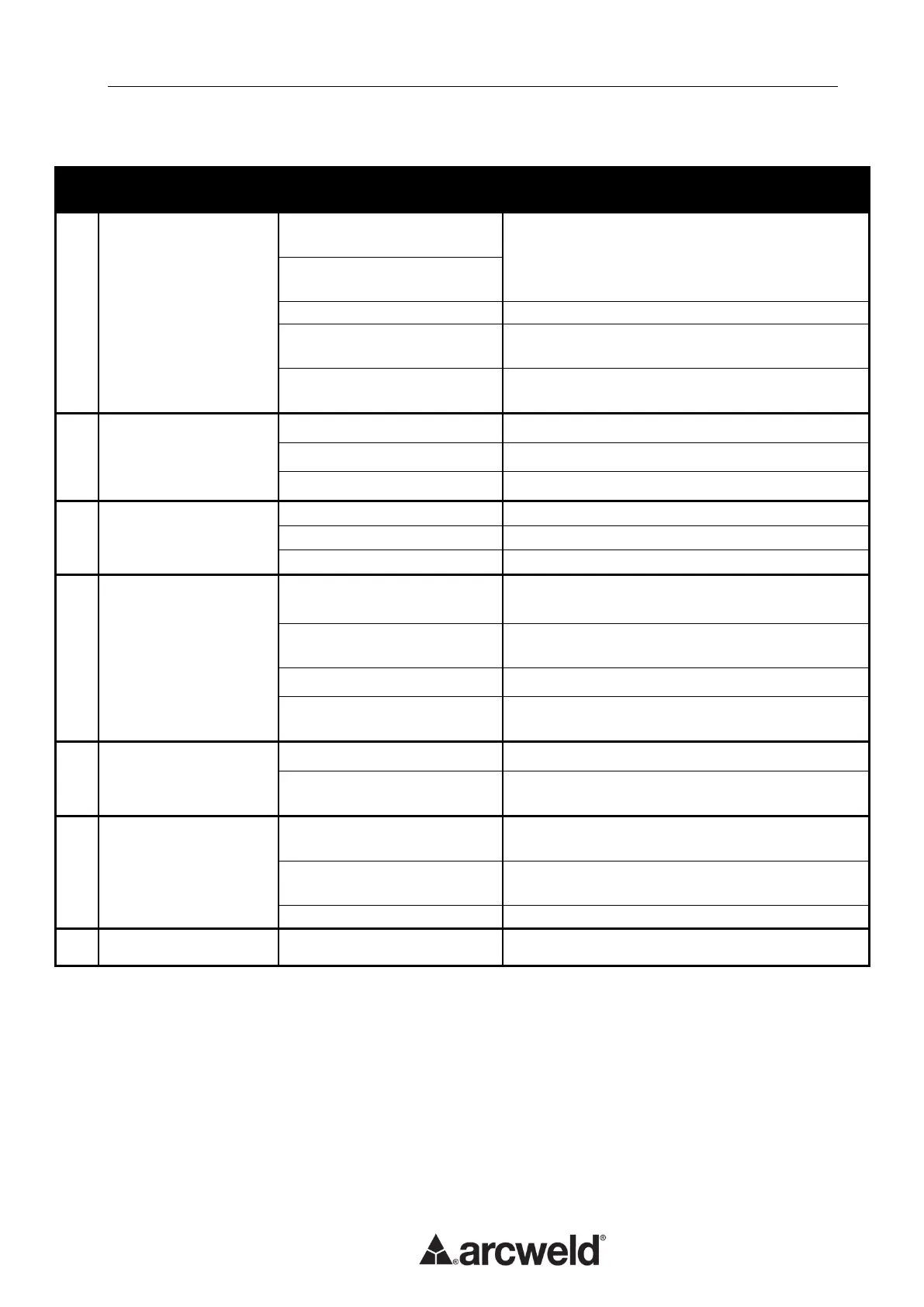

F-3 MAINTANANCE AND TROUBLESHOOTING F-3

Troubleshooting Guide

Yellow Thermal

Indicator is on

Input voltage is too high

(≥15%)

Switch off power source; Check the main supply.

Restart welder when power recovers to normal

state.

Input voltage is too low

(≤15%)

Insufficient ventilation.

Ambient temperature is too

high.

It will automatically recover when the

temperature reduces.

Exceeding the rated

duty-cycle.

It will automatically recover when the

temperature reduces.

Wire feeding motor

not working

Increase tension on drive roll

Cooling Fan not

working or turning

very slowly

Replace or repair the fan

Wire broken or disconnected

Arc is not stable and

spatter is large

Too large contact tip makes

the current unsteady

Change to proper contact tip and / or drive roll.

Too thin power cable makes

the power unstable.

Correct the input voltage.

Wire feeding resistance is

too large

Clean or replace the liner and keep the gun

cable straight.

Connect / repair work cable

Work piece has greasy, dirty,

rusty or painted

Clean work piece, ensure good electrical contact

between work clamp and job.

Torch is not connected

properly.

Gas pipe is crimped or

blocked.

Please contact our Field Service Shop.

Loading...

Loading...