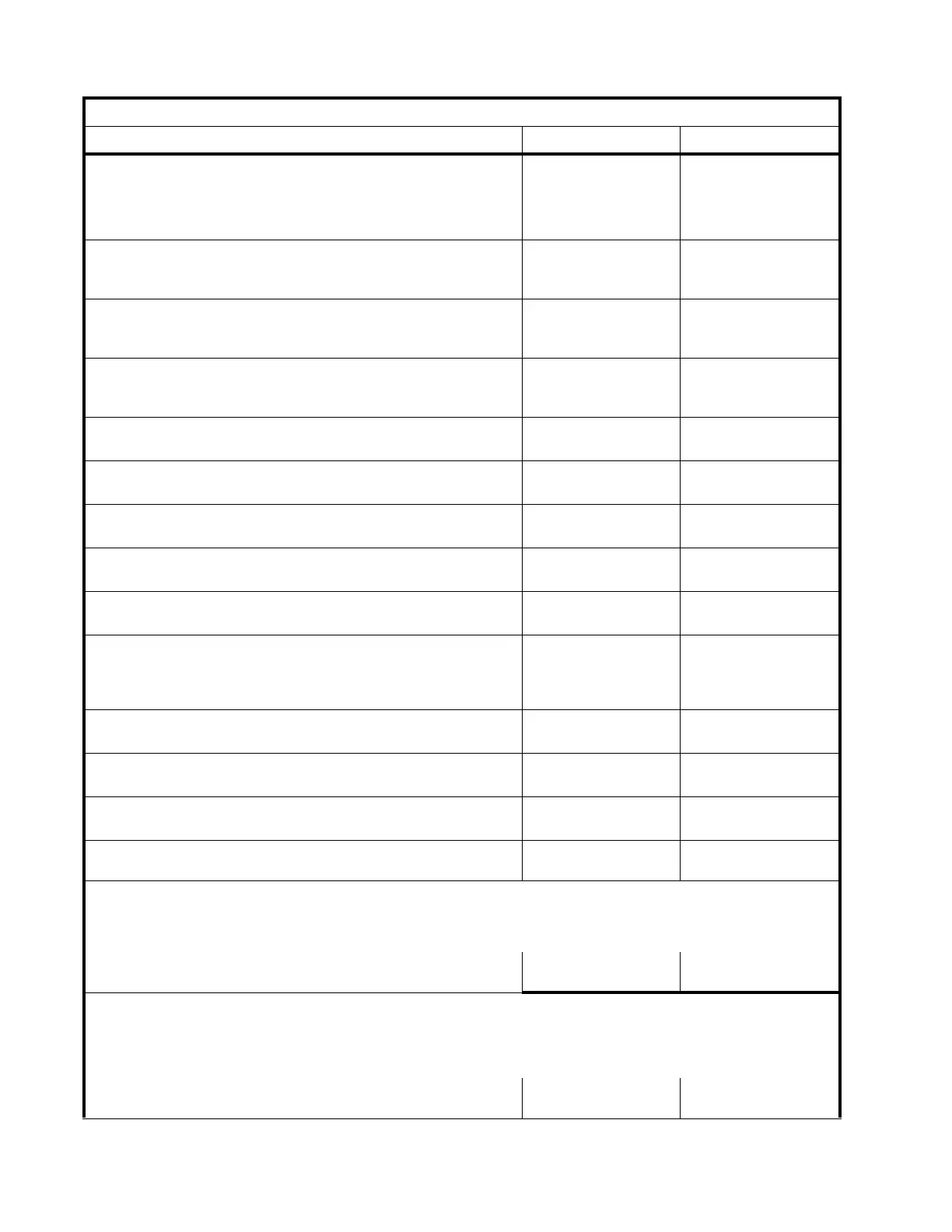

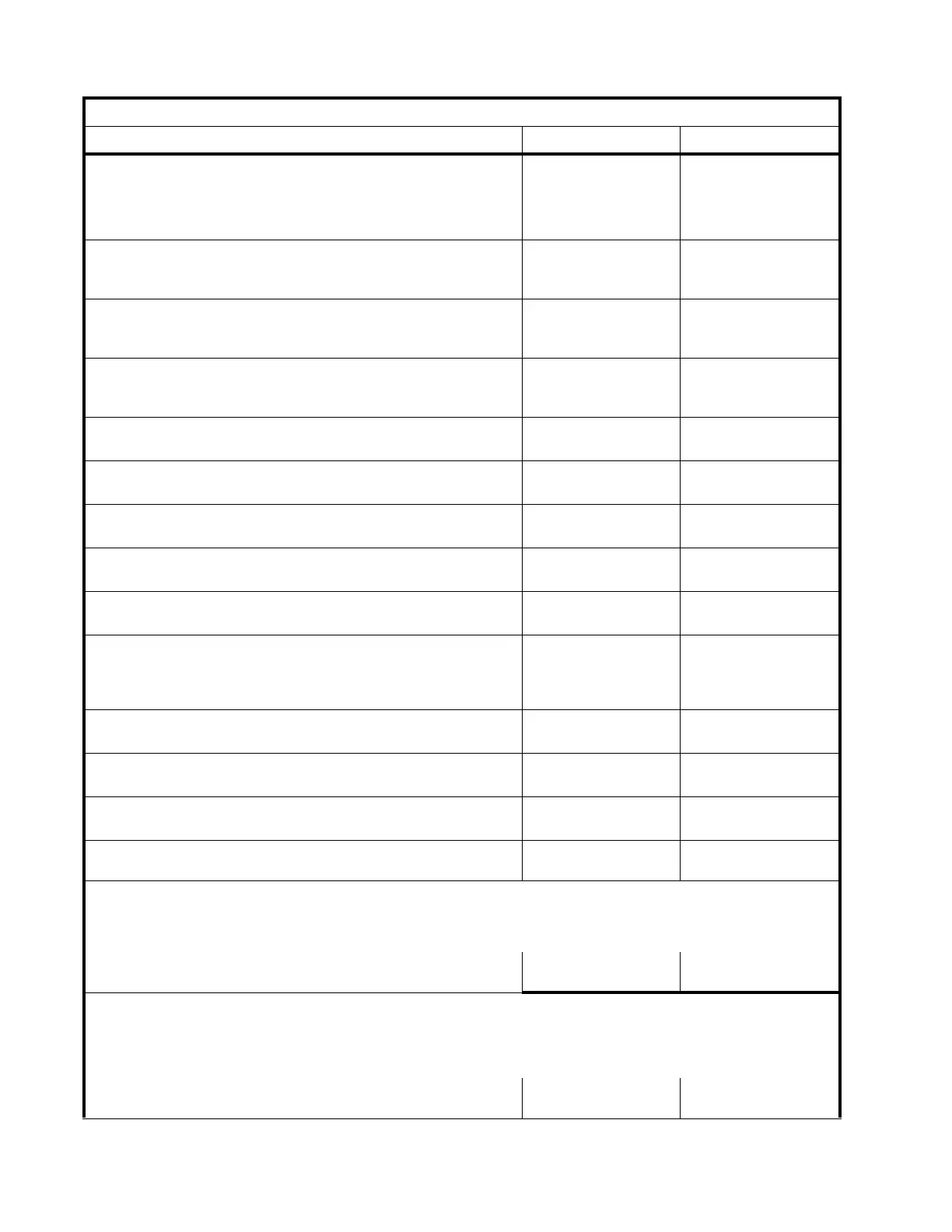

FOR MODELS: JGI, JGM, JGN, JGP AND JGQ SECTION 3 - START UP

PAGE 3-4 9/08

START-UP CHECK LIST - ITEMS TO CHECK IN THE FIELD AT COMMISSIONING

Description Date Checked Date Verified

1. Check and verify the top cover data plate of the compres-

sor frame for compressor design limitations such as rod

load, maximum and minimum speed, and maximum lube

oil temperature.

Commissioning Agent:

__________________

Distributor:___________

2. Check and verify the availability of correct start-up spares,

hand tools, special tools, compressor parts list and draw-

ings, and technical manuals at installation.

Commissioning Agent:

__________________

Distributor:___________

3. Check and verify the Ariel lube sheet and Lubrication

Specification matches the recommended oil grade and vis-

cosity for the service.

Commissioning Agent:

__________________

Distributor:___________

4. Check and verify all lube oil piping cleanliness per Ariel

lubrication specifications (see Technical Manual, Section

4).

Commissioning Agent:

__________________

Distributor:___________

5. Verify lube oil storage and supply line cleanliness per ER-

56.06. Verify crankcase oil supply isolation valve is open.

Commissioning Agent:

__________________

Distributor:___________

6. Verify prelube piping cleanliness per ER-56.06 and correct

circuit operation.

Commissioning Agent:

__________________

Distributor:___________

7. Verify there is an oil cooler and high temperature shut-

down for the oil into the compressor frame.

Commissioning Agent:

__________________

Distributor:___________

8. Verify whether the temperature control valve installation is

blending or diverting (blending preferred). _____________

Commissioning Agent:

__________________

Distributor:___________

9. Check compressor crankcase oil level controller for proper

installation, operation, levelness, and venting.

Commissioning Agent:

__________________

Distributor:___________

10. If applicable, check cooling water circuit cleanliness for the

oil cooler and cooled packing per Technical Manual. Verify

correct routing and test pump rotation. Set pressure appro-

priately per Technical Manual and leak test.

Commissioning Agent:

__________________

Distributor:___________

11. Verify correct filter element installation. Prime the oil filter

element and all lube oil piping with oil.

Commissioning Agent:

__________________

Distributor:___________

12. Verify proper compressor crankcase oil level before start-

ing (about 7/8 full in site glass).

Commissioning Agent:

__________________

Distributor:___________

13. Verify correct installation of a low oil pressure shutdown

tubed to the downstream side of the oil filter.

Commissioning Agent:

__________________

Distributor:___________

14. Operate pre-lube system.

Commissioning Agent:

__________________

Distributor:___________

15. OPTIONAL STEP: Record “out of plane” readings (pre-grout) - see ER-82.

Drive End _________ _________ _________ _________ _________ _________ Auxiliary End

_________ _________ _________ _________ _________ _________

Commissioning Agent:

__________________

Distributor:___________

16. Record soft foot readings. More than 0.002 inches (0.05 mm) pull-down on any frame foot requires cor-

rection. See Technical Manual.

Drive End _________ _________ _________ _________ _________ _________ Auxiliary End

_________ _________ _________ _________ _________ _________

Commissioning Agent:

__________________

Distributor:___________

Loading...

Loading...