Owner/Operator Manual

Manuel Du Propriétaire/Utilisateur

Models

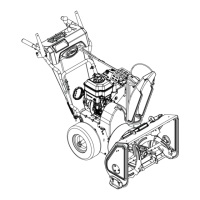

920013 – Compact 22 LE

(Serial No. 35000 and up)

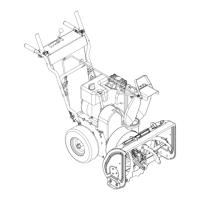

920014 – Compact 24 LE

(Serial No. 35000 and up)

920 Series

Sno-Thro

®

04335600C 11/11

Printed in USA

ENGLISH

FRANÇAIS

Gasoline containing up to 10% ethanol (E10) or up to 10% MTBE (methyl tertiary butyl ether)

is acceptable for use in this machine.

The use of any gasoline exceeding 10% ethanol (E10) or 10% MTBE will void the product

warranty.

Il est possible d’utiliser de l’essence contenant jusqu’à 10% d’éthanol (E10) ou 10% de

MTBE (éther méthyl-tertiobutylique) sur cette machine.

L’utilisation d’une essence contenant plus de 10% d’éthanol (E10) ou de 10% de MTBE

annulent la garantie

.